COOLING

SYSTEM

COOLING

Draining

Pull

thc

hcrtcf

control knob to thc lLrll\

open position.

Reirove the mdielor fillcr

cap

I

open the tap in thc bottonr of thc

radirlor

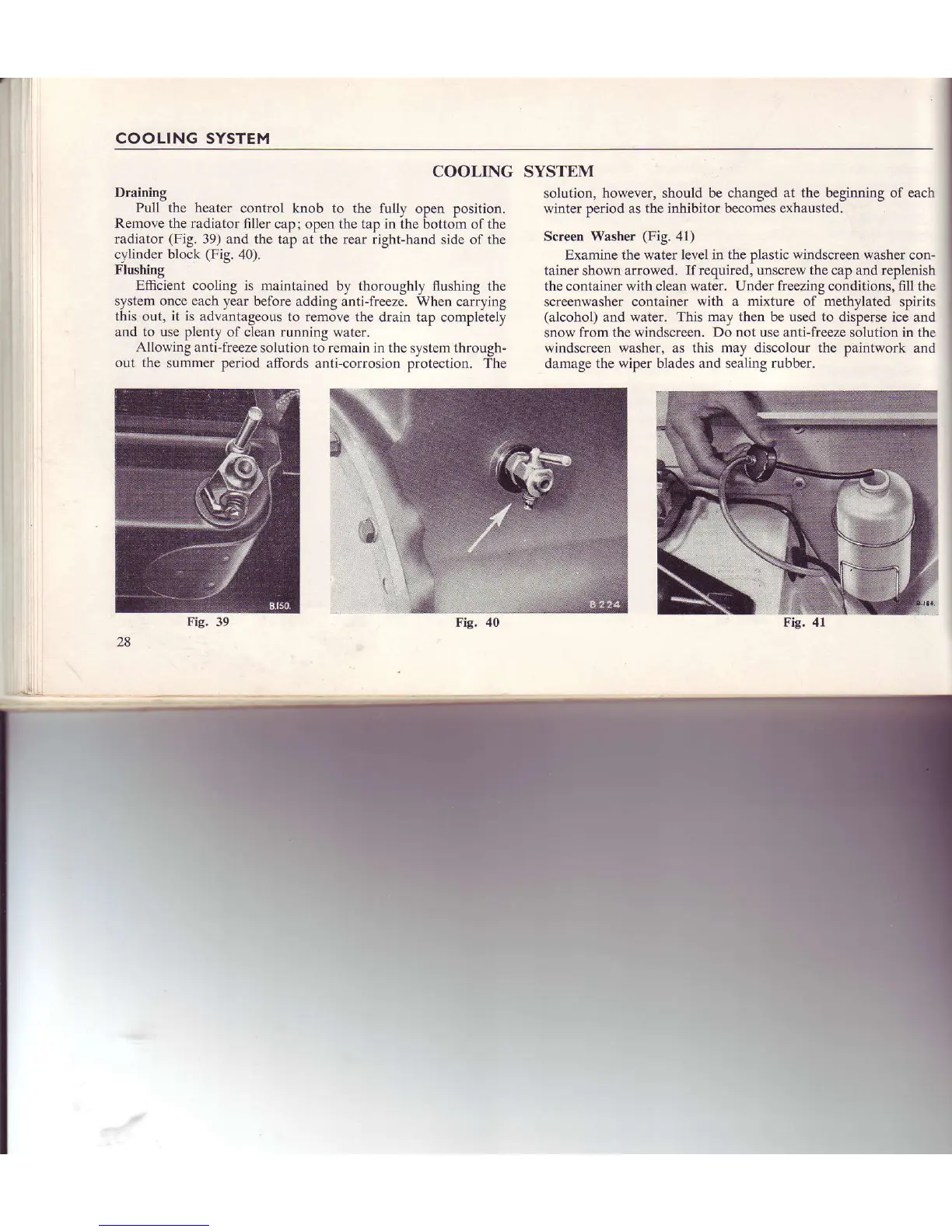

(l.ig.

-'19) and thc

tap ilt thc rcitr riqht-hand side of the

cvlinder

block

(Fiq. :10).

Flushing

Eflicicnt coclinq is Inaintaincd

tTv lhoroughh IlLrshing lhe

s\stcn1 ollcc cilch

vcilr

bclbre addinq anti-f|'cczc.

Whcn ci,trr\i g

this out, il is advdnliLqcous

to rento\e the drain tep completelv

rnd

to usc

llcnt\

ol clelln runninq watcr.

Allo\inq anti frcczc

solLrlion lo retrain in thc

st'stcnt

through-

oul lllc sLrnr|nar

pcriod

allbfds

anli-corI(rsion

pfotcction.

Thc

SYSTEM

solution.

however. should Lre changcd

at thc bcginning of

each

wi le. period as

thc inhibitor beconres exhausted.

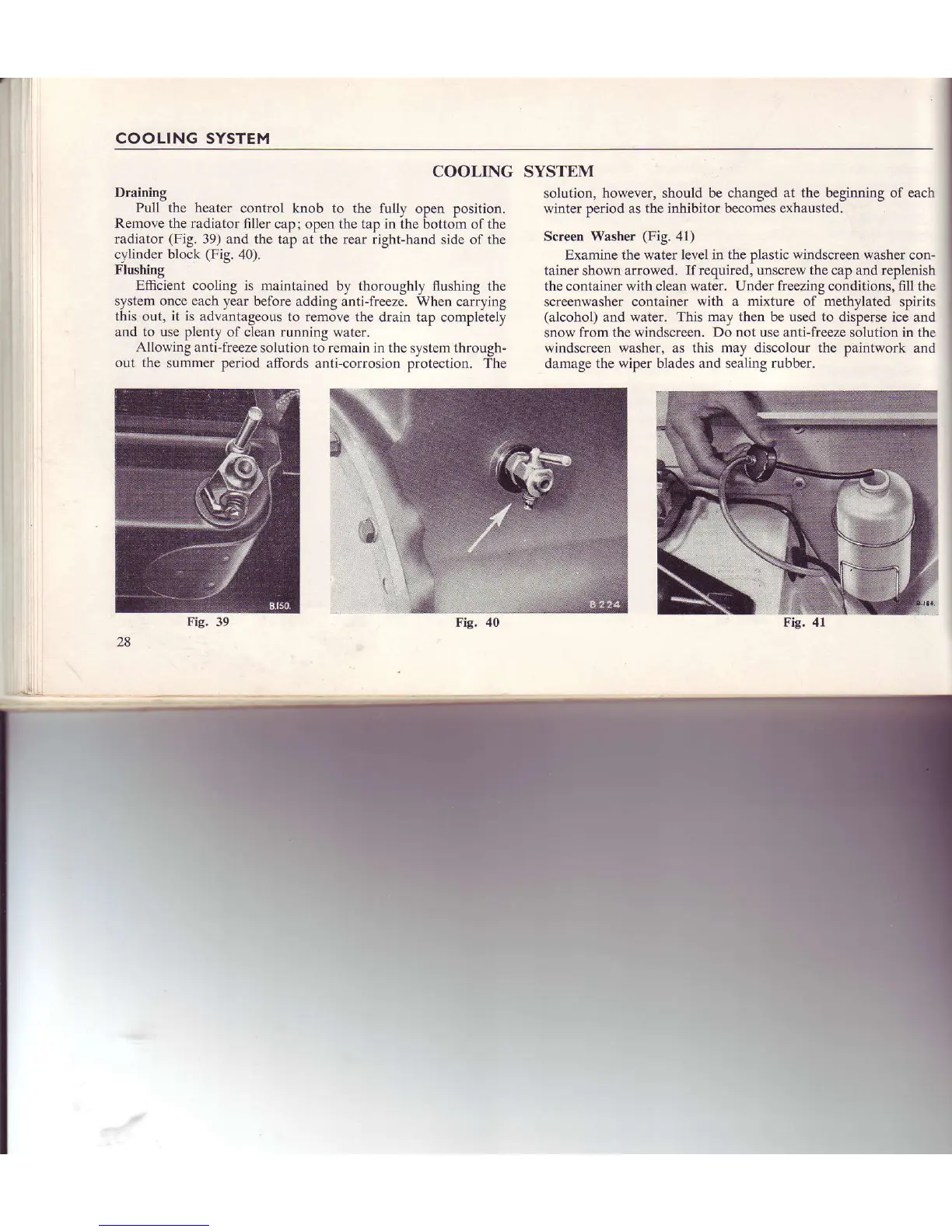

Scrccn Washer

(Fig.

.11)

Ex!rminc

thc

watcr le\'cl in the pltstic windscrcen $ashcr

co'r-

taincr

sh()wn

arrowed. requlred. unscre$ the cap and replenish

the container \\ith cleln

\!atcr.

LJndcI

freezing

conrlitjons. fill thc

scrccnwashcr container

$ith a nrixlLlre of fiethvlatcd

spirits

(alcohol)

and $ater. Ihis n'rav thcn be used to disperse ice

and

sr'lo\! lion'r the

\\indscrecn. Do n()l usc anti-frecze

solution in thc

\\indscrccn \\ashe]-. as this nrar discolour the piiintwork

and

dallllge the \!iper bllrdes rrrd scalrng

fLrbhcr.

,10

Irig.

39

Fic.

Fig.

4l

l8

Loading...

Loading...