EN

UNI 30 E 17261 - 561.228 7 - USE AND OPERATION

Cap. 7 - Pag. 1/14

THIS MANUAL IS PROPERTY OF - ANY TOTAL OR PARTIAL REPRODUCTION IS STRICTLY FORBIDDEN

7.1 OPERATING PRINCIPLE

The mixture, whether prepared separately with any concrete mixer or mixer, or packed in the mixer incorporated in the

plastering machine (EMF version), is made to fall onto the machine vibrating sieve.

The sieved mortar falls into the hopper. From here it is pumped via pump with gravitational valves to the place of use and then

sprayed onto the walls using a gun (different depending on the type of material used) into which the material and the air

supplied by the compressor, incorporated into the machine, flow.

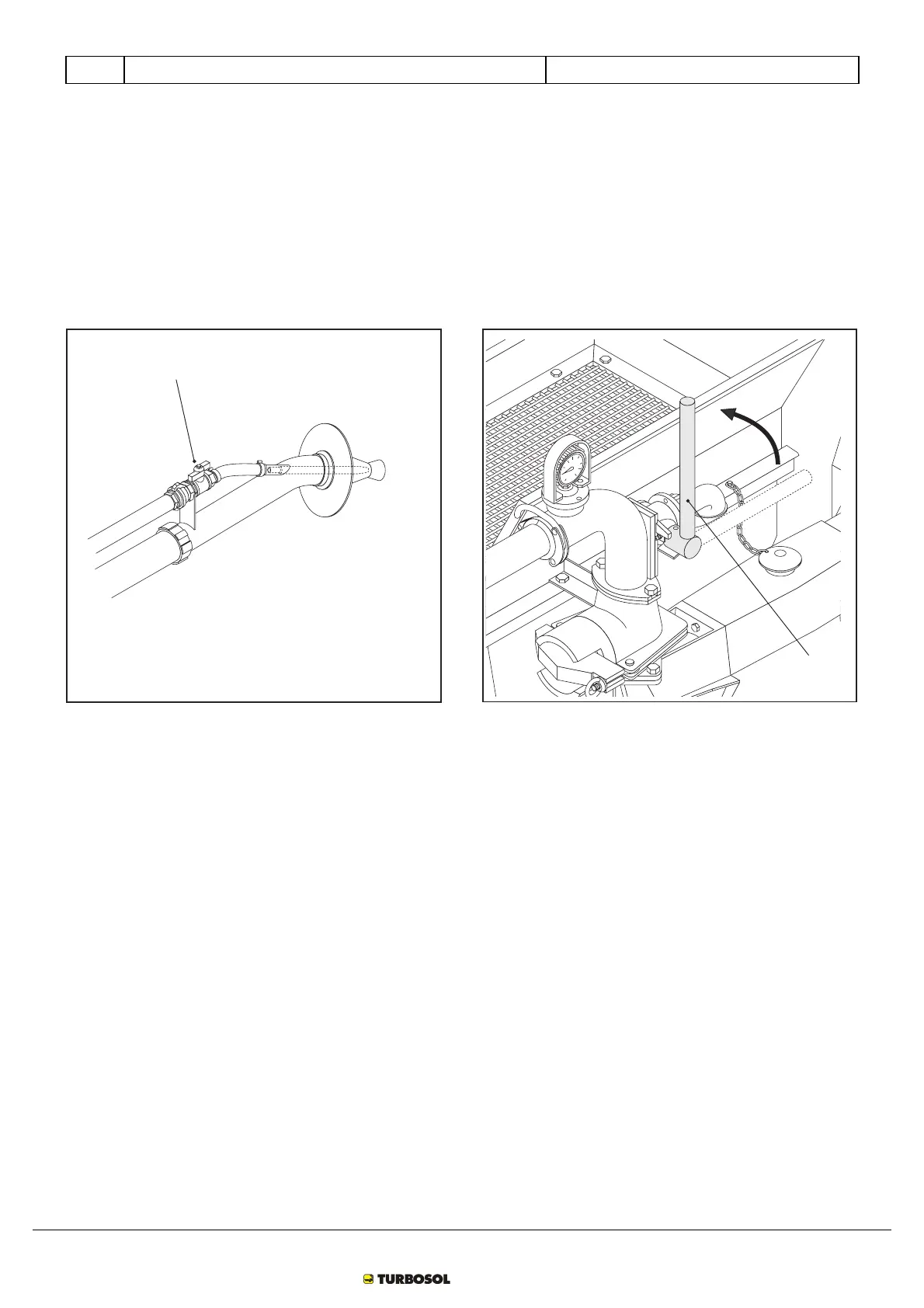

Machine start and stop are controlled directly by the operator at the gun, by opening and closing the air cock (FIG.19-REF.1)

positioned on the mortar gun.

1

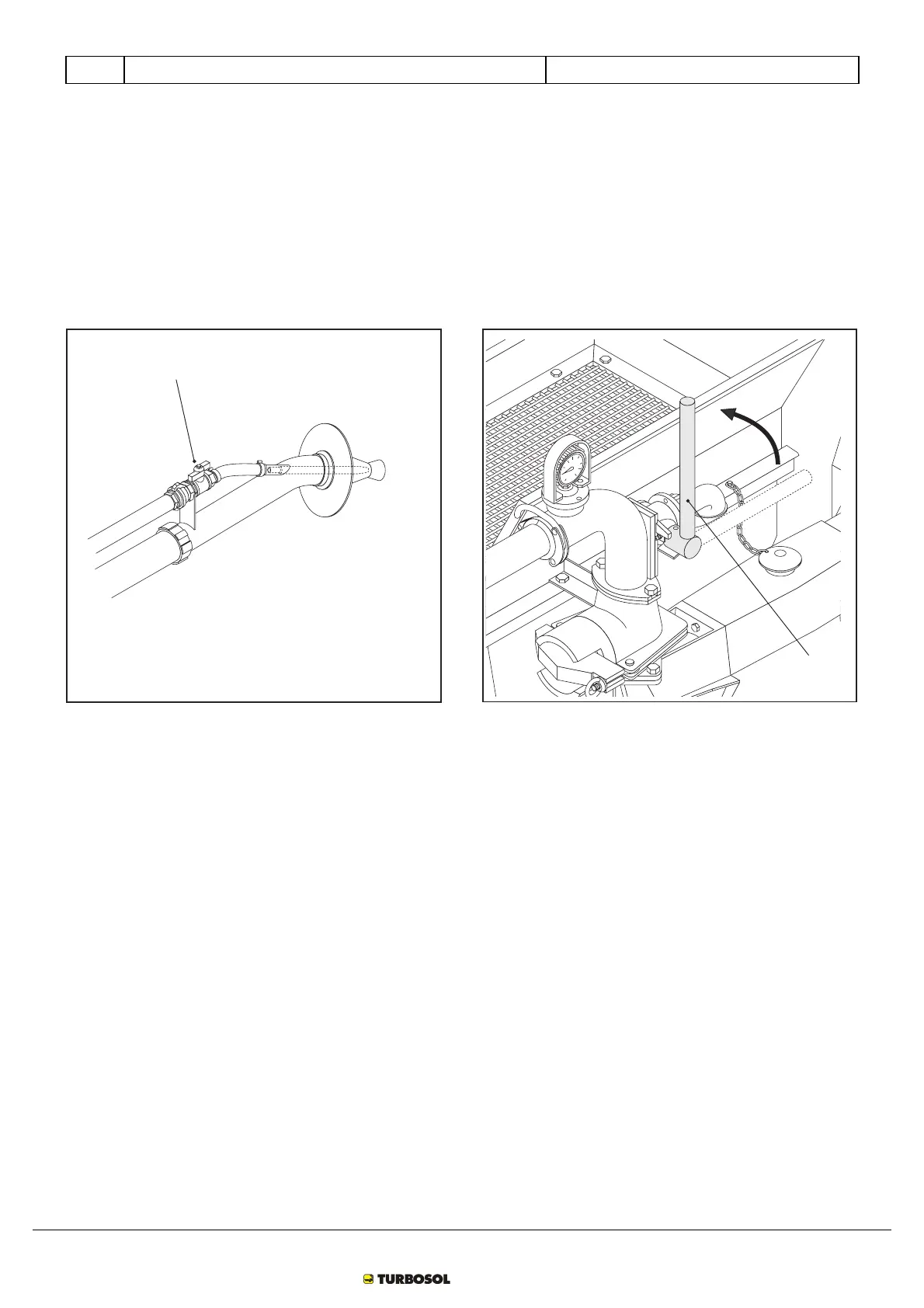

1

FIG.19 FIG.20

As a general indication, with deflectors that have a smaller diameter, the material is projected with a wider span and vice versa.

Using the by-pass lever (FIG.20-REF.1) it is possible to divert the flow of material towards the piping (horizontal position) or in

circulation towards the hopper (vertical position).

During the start-up phase, in this way it is possible to start the machine without load and, in case of blocking of the pipes or

gun, discharge the pressure present in the piping (vertical position).

The mortar pump overpressure safety device, releases motor transmission from the motor to the pumping unit to prevent

dangerous overloads to the pipes and pumping unit.

7.2 PUMPABLE MATERIALS

Below find some fundamental concepts in the realisation of traditional mixtures, which must be conveyed using the UNI 30. The

aggregates must be within the particle size curve (FIG.21): mixed sand with particle size 0-6 mm.

Loading...

Loading...