EN

UNI 30 E 17261 - 561.228 8 - MAINTENANCE

Cap. 8 - Pag. 3/6

THIS MANUAL IS PROPERTY OF - ANY TOTAL OR PARTIAL REPRODUCTION IS STRICTLY FORBIDDEN

1

3

3

4

1

2

2

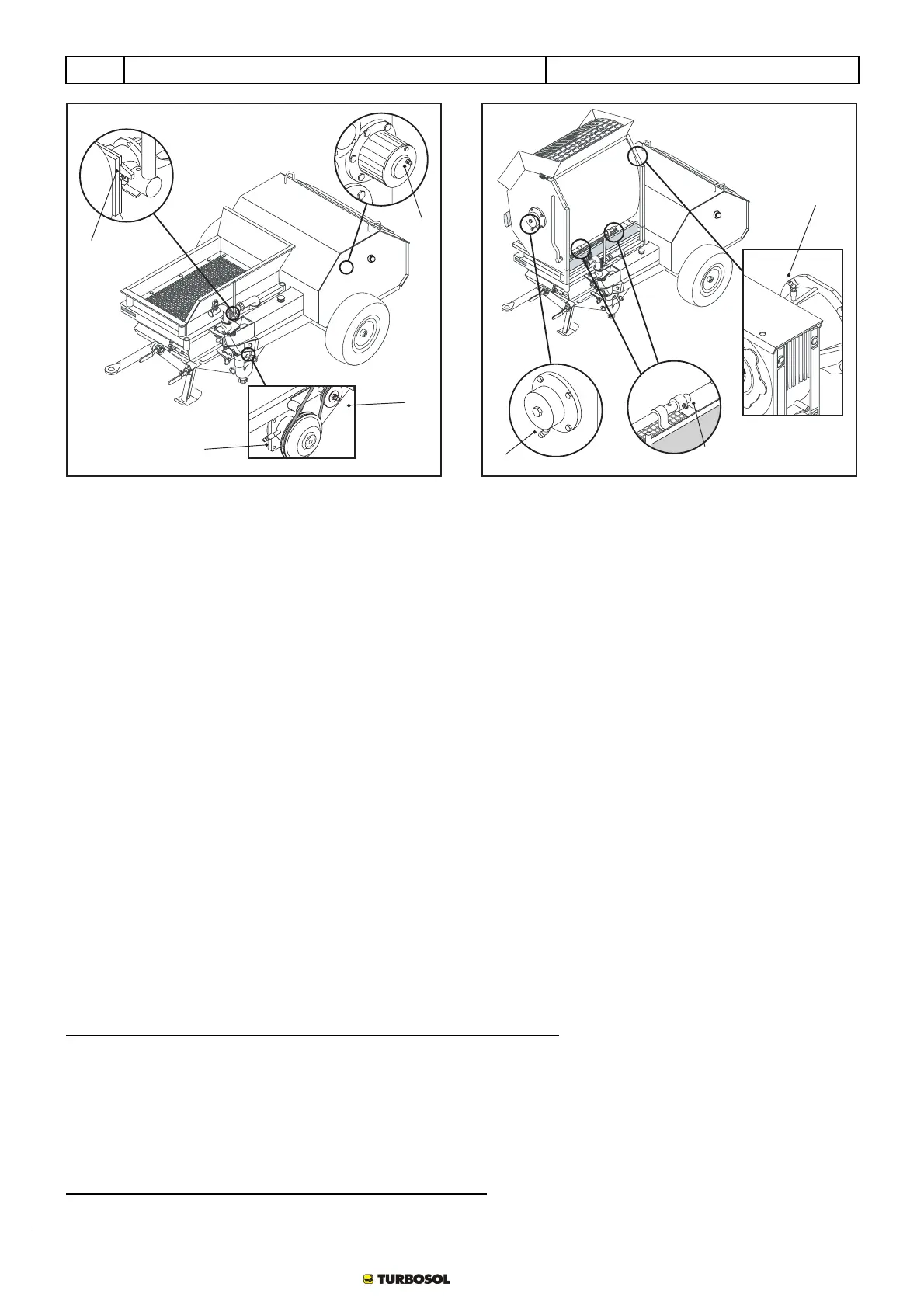

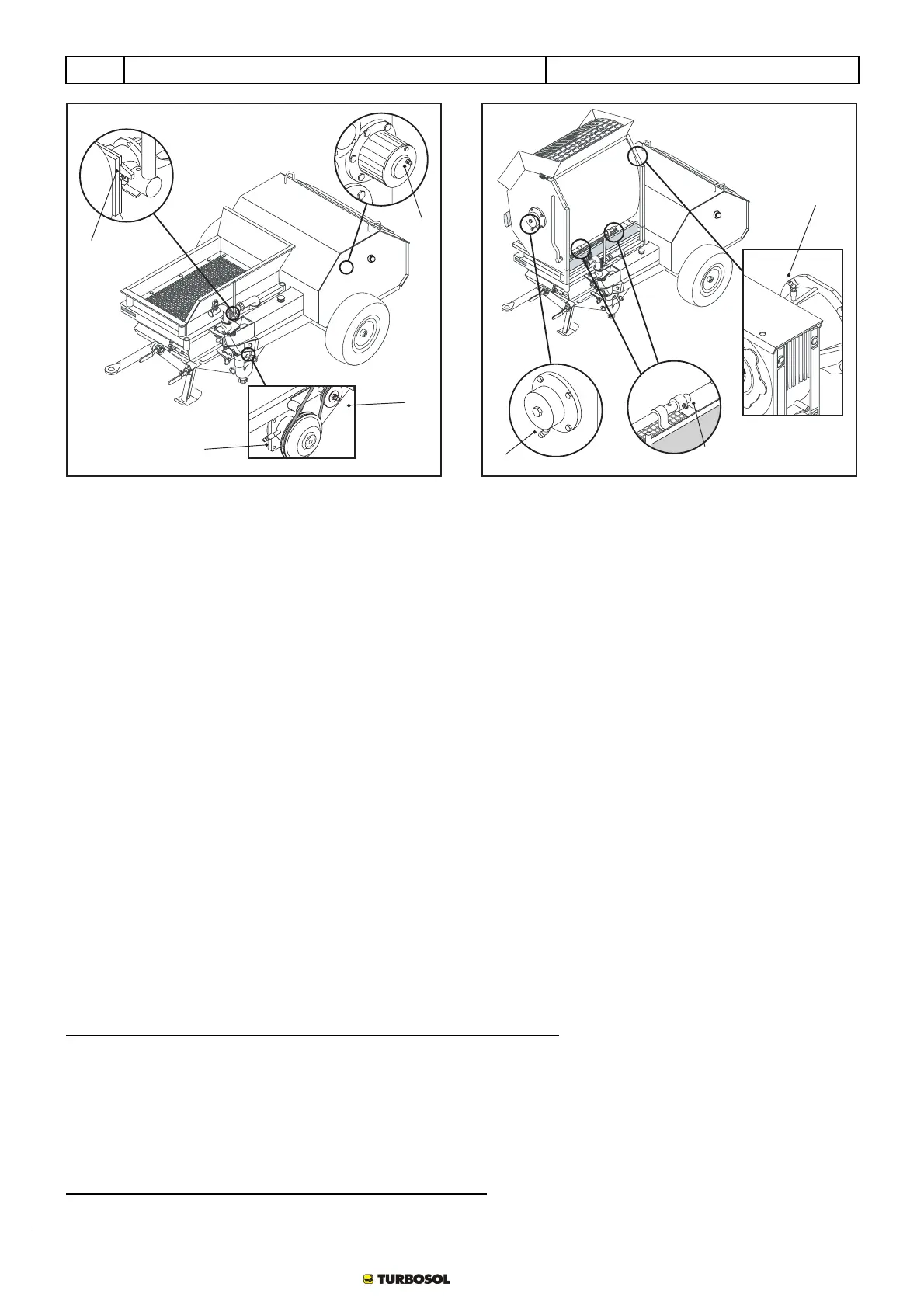

FIG.52 FIG.53

In the version with mixer (EMF) also grease: the hatch shaft (FIG.53-REF.2), the blind support body (FIG.53-REF.1), the ring

support flange (FIG.53-REF.3).

For the execution of the operation to be correct, the grease must escape from the sealing cups.

If you forget to perform this operation, in a brief period of time (days) the sealing gaskets and the supports are ruined.

The operator must also make sure that programmed maintenance is respected, by the qualified staff, described successively.

The Manufacturer is not liable for any consequences deriving from the failure to comply with the maintenance table or for the

operator performing operations that are the responsibility of qualified staff.

Period of inactivity of the plastering machine.

When putting the plastering machine in storage for a period of inactivity the following operations and checks must be

performed:

• Discharge the water contained in the lubrication tank, removing the discharge cap.

• Disassemble the hopper discharge cap situated on the intake collector.

• Disassemble the various pieces of pipe collecting them in just as many rolls, so that they are not bent.

• Protect painted parts of the machine from rust by spraying them with a layer of naphtha or oil.

• Do not spray the rubber parts.

• Lift the machine so that the wheels do not touch the ground.

• Make sure that the last machine washing has taken place in compliance with the instructions; that the various fittings have

been spread with grease and that all tools and accessories have been put in the relative box.

8.2 A CURA DEL PERSONALE ABILITATO

OPERATIONS TO BE PERFORMED EVERY MONTH OR EVERY 100 HOURS

• Compressor oil replacement.

OPERATIONS TO PERFORM EVERY 3 MONTHS OR 250 HOURS

Loading...

Loading...