EN

UNI 30 E 17261 - 561.228 8 - MAINTENANCE

Cap. 8 - Pag. 5/6

THIS MANUAL IS PROPERTY OF - ANY TOTAL OR PARTIAL REPRODUCTION IS STRICTLY FORBIDDEN

Check:

• Check the flexible air pipes.

• Check and if necessary replace the trapezoidal belts.

• Check piston, balls, seals, manometer, by-pass, and generally that there are no anomalies.

• Replace the oil in the compressor

• Replace the oil in the pump reducer.

• Replace the oil in the mixer reducer.

OPERATIONS TO PERFORM EVERY YEAR OR 1000 HOURS

• Replacing the worn valve seats.

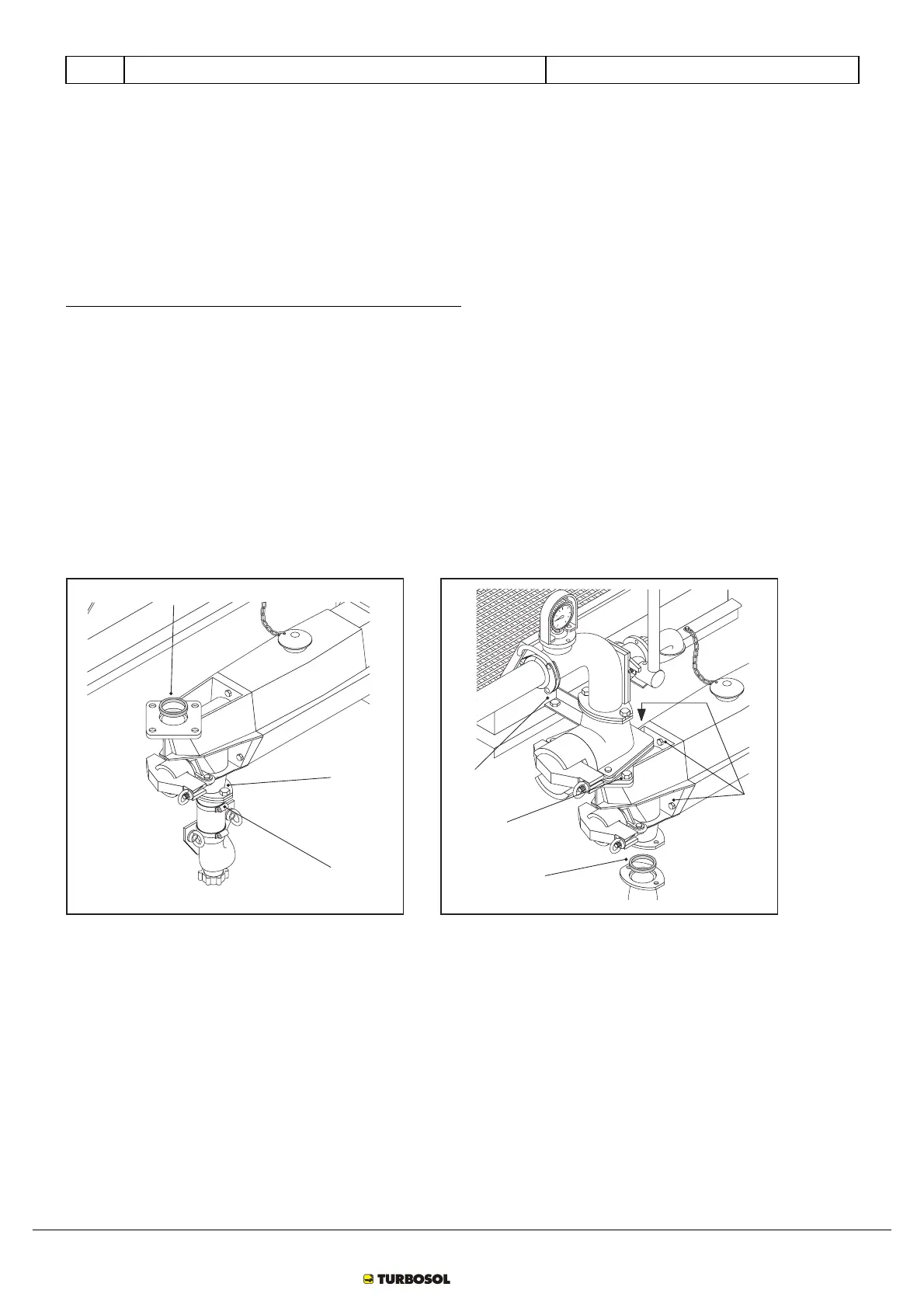

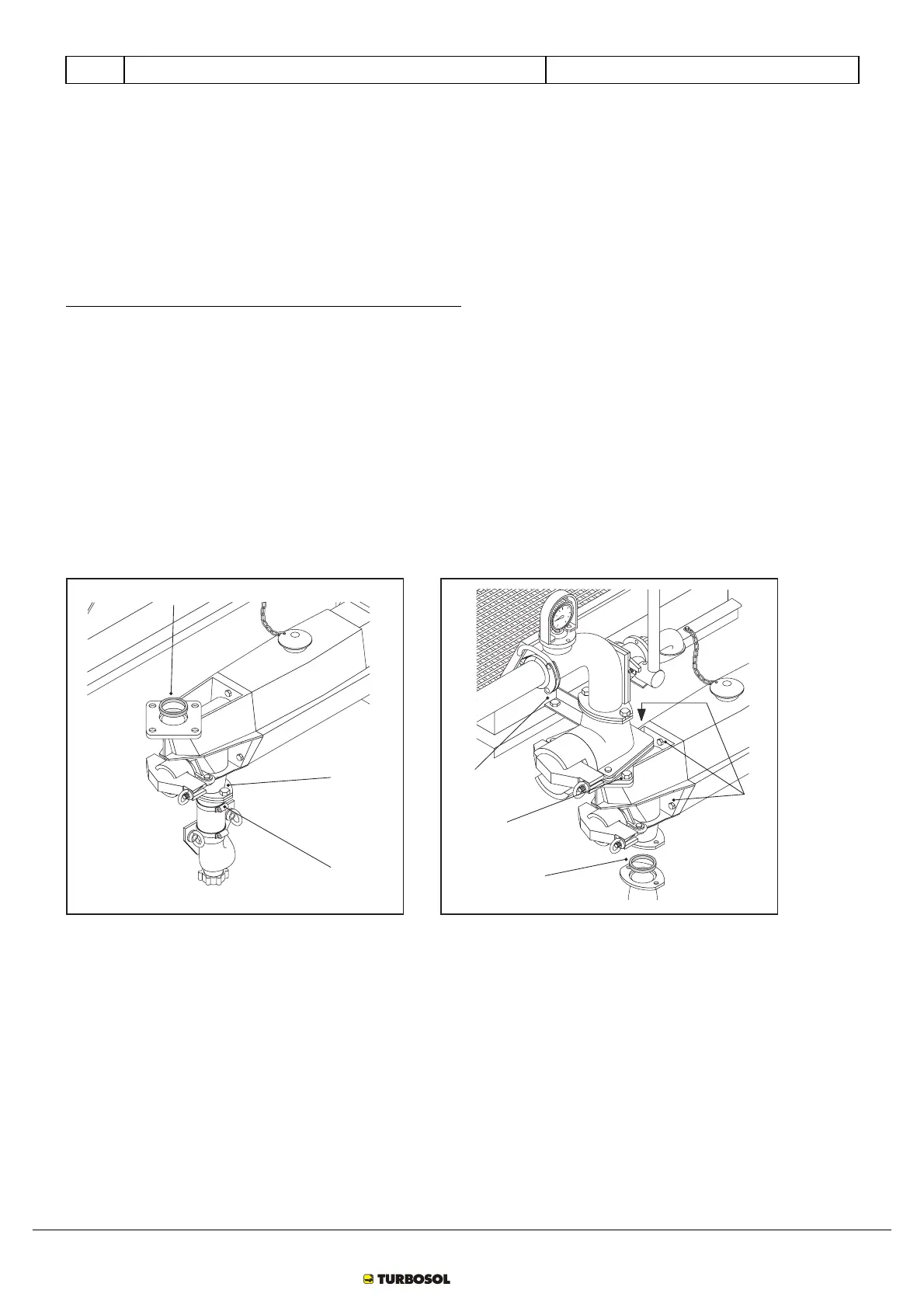

Flow valve seat.

Loosen the screw (FIG.58-REF.1) that blocks the flow valve body to the hopper and the four screws (FIG.58-REF.2) that fix it

onto the intake valve body.

Remove the worn flow valve seat (FIG.57-REF.1) and replace it.

Re-mount the valve body fixing it using the relevant screws.

Intake valve seat.

Unscrew the hose clamps (FIG.57-REF.2) that fix the rubber fitting, which connects it to the intake collector and the two screws

(FIG.57-REF.3) that fix the intake valve body to the intake collector flange.

Remove the worn intake valve seat (FIG.58-REF.3) and replace it.

Rimontare la flangia di aspirazione.

3

4

1

2

3

2

1

FIG.57 FIG.58

Loading...

Loading...