5

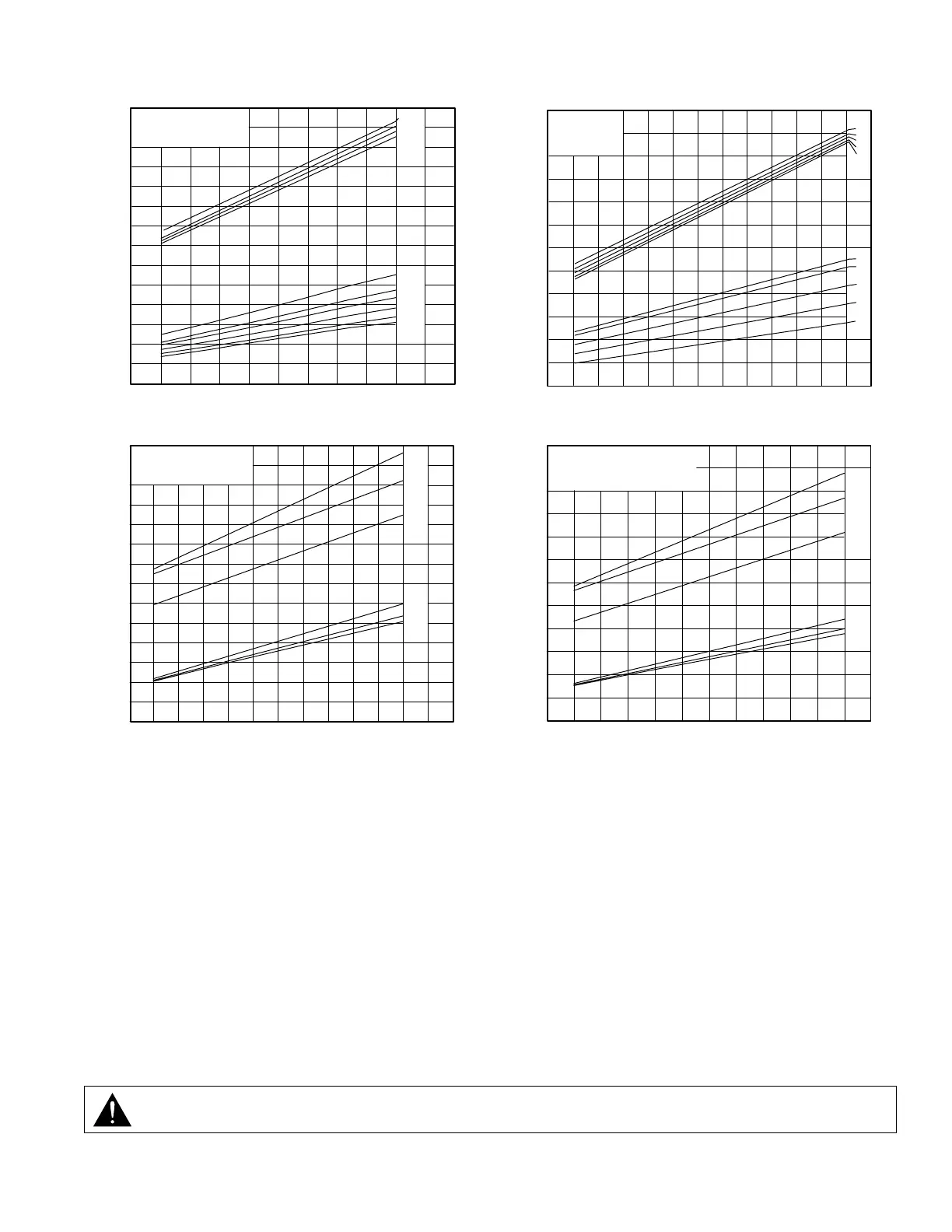

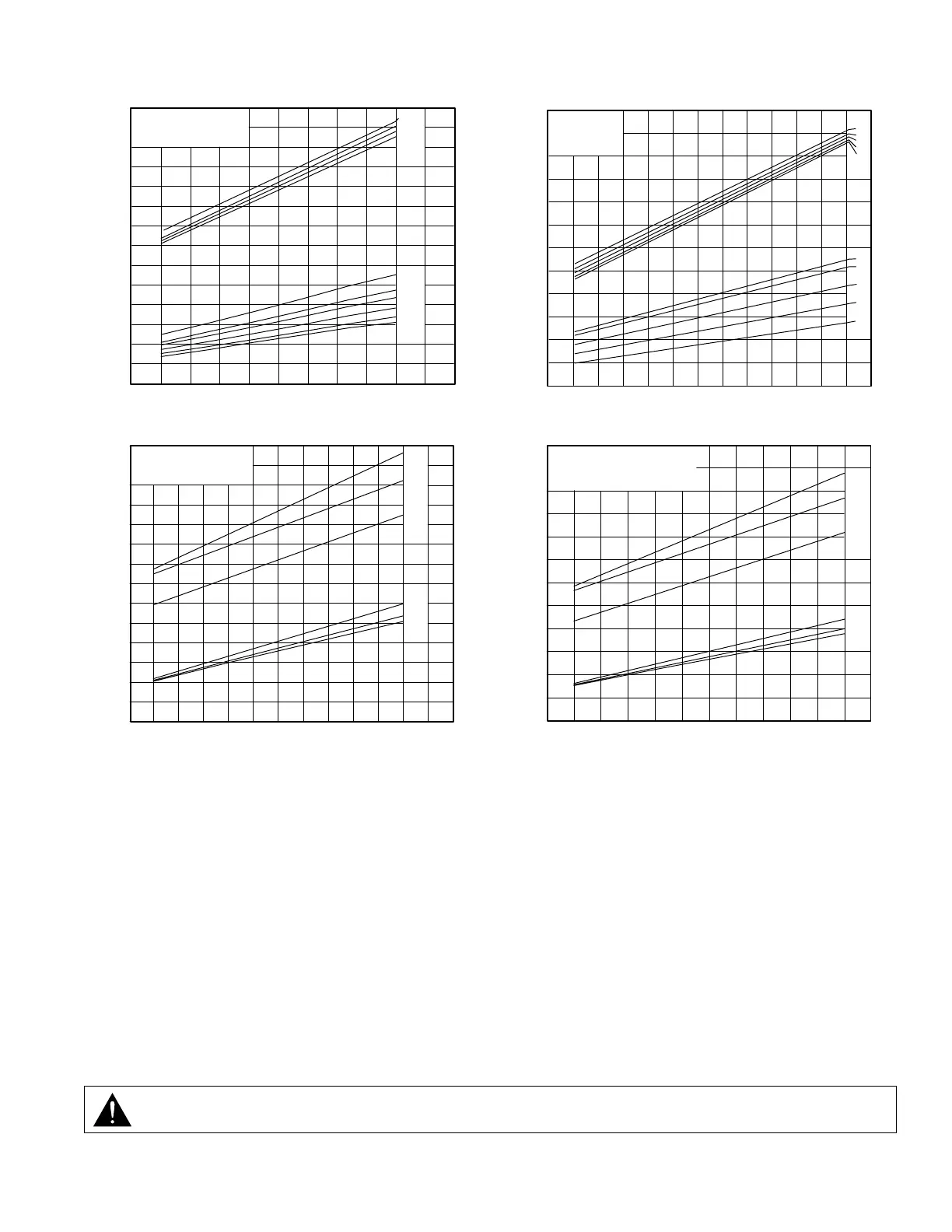

PERFORMANCE CURVES

OPERATING THE BLOWER

1. Inspect blower mounting, drive line, PTO, and air lter for integrity.

2. Remove Camlock dust cap and connect the hot air hose.

3. Follow trailer instructions regarding product hose connection and valve operation.

4. Slowly engage PTO with engine at idle, and blower unloaded. Bring up to operating speed and lock engine at recommended

speed (Shown in cab)

5. Unload trailer as per trailer manufacturer’s recommendation and do not exceed maximum tank pressure or maximum blower

pressure.

6. While discharging, visually check blower for vibration, mechanical noise or excessive heat.

7. If relief valve is opening, adjust proportioning valve to reduce tank pressure.

8. Reduce pressure to zero as per trailer manufacturer’s instructions.

9. Disengage PTO

10. Disconnect blower hose and replace Camlock dust cap.

WARNING: The blower and accessories become hot and will cause serious skin burns on contact. Rotating

machinery is dangerous. Always wear ear protection when in close proximity to the blower.

BHP

AIRFLOW BASED UPON

INLET CONDITIONS OF:

14.7 PSIA & 70° F

0

10

20

30

40

50

60

600

550

500

450

400

350

300

250

1000 1250 1500 1750 2000 2250

PSIG

25

20

18

15

12

10

PSIG

10

15

20

25

CFM

Airflow at Inlet (CFM)

Horsepower (BHP)

1000 1200 1400 1600 1800 2000 2200

10

14

17

17

14

10

0

5

10

15

20

25

30

200

250

300

350

400

450

500

550

600

RPM

BHP

AIRFLOW BASED UPON

INLET: 70° F

DISCHARGE: 29.92” Hg Abs.

"Hg

"Hg

CFM

T650 VACUUM CURVE

Airflow at Inlet (CFM)

Horsepower (BHP)

AIR FLOW AT

STANDARD INLET

CONDITIONS

1013mb + 20°C

kW

0

10

20

30

40

50

60

0.5

1

1.5

2

2.2

bar

0.5

1

1.5

2

2.2

bar

400

500

600

700

800

900

1000

1100

m³/h

1200 1400 1600 1800 2000 22001000

RPM

Airflow at Inlet (m³/h)Kilowatts (kw)

350

475

575

575

475

350

AIRFLOW BASED UPON

INLET: 20°C

DISCHARGE: 1 BARA

DENSITY @ 20°C & 1 BARA: 1.2 KG/M³

kW

0

5

10

15

20

25400

300

500

600

700

800

900

1000

1100

m³/h

1200 1400 1600 1800 2000 22001000

mbar

mbar

RPM

Airflow at Inlet (m³/h)Kilowatts (kw)

Loading...

Loading...