7

CHECK VALVE

• Minimum restriction for application and mounted downstream of the relief valve.

• The check valve should be sized for maximum air flow (CFM).

SUCTION & DISCHARGE PIPING

• All piping should be free and clear of any welding slag or foreign material.

• The suction piping requirements is a minimum of 4’’ (100 mm) diameter for proper flow to the blower.

• The discharge piping is recommended to be 3” (80 mm) diameter.

CAUTION: Do not use a rubber elbow in the suction line during vacuum operation. The elbow will fail causing the

blower to overheat. This will cause damage to the blower.

MUFFLERS & DISCHARGE FILTRATION

• Minimum restriction for application

• Mount downstream of relief valve.

CAUTION: For food-grade applications, always install a properly sized food-grade discharge filter downstream of

the muffler (between muffler and trailer).

VACUUM VALVE

• A vacuum valve and filter must be installed to properly protect

the blower from overheating while vacuum loading.

• Size for proper air flow and vacuum rating.

• This valve should be located before the blower inlet air filter.

Normally this valve is mounted on the trailer.

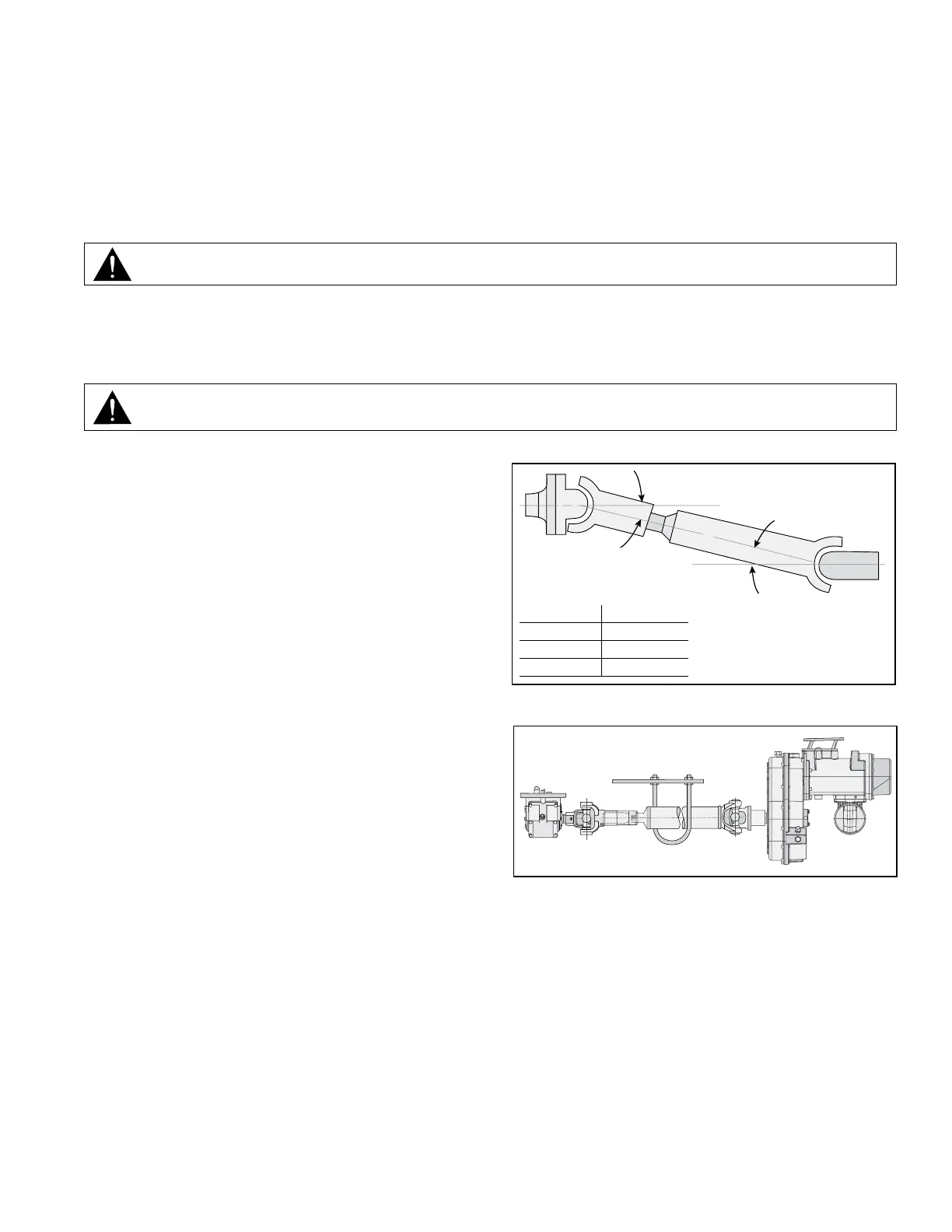

PTO DRIVE SHAFT

• Blower drive shaft and PTO output shaft must be parallel and

in phase. Maintain axis within one degree in vertical plane to

ensure low vibration during operating conditions.

• Use a minimum of a 1300 series (SAE 1300 or DIN 100) drive

shaft that has been correctly balanced at the operating RPM.

• Do not force yokes onto the blower drive shaft or the PTO

output shaft.

• T650 drive shaft is 1 5/8” diameter with a 3/8” keyway and

2-9/16” inches long.

• T950H drive shaft is 40 mm diameter with a 12 mm keyway

and 65 mm long.

• Refer to Figure 2 to ensure that the drive shaft is at the

proper angle.

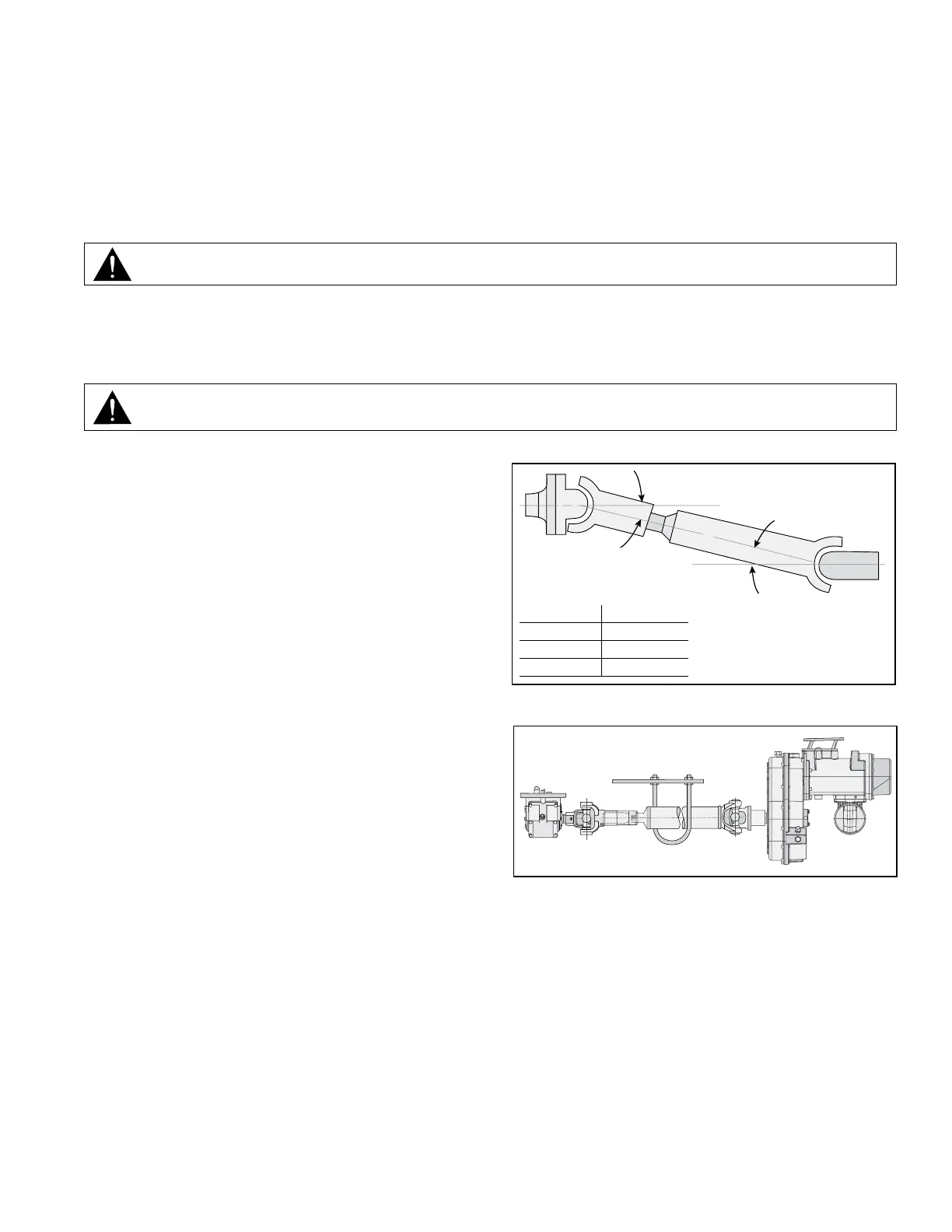

• A “U” bolt hanger (Figure 3) should be installed to prevent the

drive shaft from damaging the blower or PTO if the slip yoke

comes apart. The slip joint should be half compressed. This

will also stop the drive shaft from dropping to the ground, and

causing potential thrust damage to the blower.

DRIVE SHAFT ANGLE

(Horizontal Plane)

SPEED ANGLE

1250 RPM 12 Degrees

1650 RPM 10 Degrees

2000 RPM 8 Degrees

THE ANGLE OF THE

DRIVE SHAFT SHOULD

NOT EXCEED 12°

Figure 2. Drive Shaft Angle

Figure 3. U Bolt Hanger Installation

Loading...

Loading...