33

Installation instructions

ENGLISH

CH

C

P.

CH

P. Car.

DHW

Stemp.

ACC

Y4

1

2

3

4

1

2

3

1

2

3

4

5

6

Y3

Y2

12 11 10 98 765

4321

0

1

2

3

4

5

6

7

8

9

981011121314

2134567

Jp2

L

Y4

1

2

3

4

1

2

3

1

2

3

4

5

6

Y3

Y2

12 11 10 98 765

4321

0

1

2

3

4

5

6

7

8

9

981011121314

2134567

Jp2

SE

24 V -DC

CM 140 - cascade manager

24 V -DC

BR

BK

R

S

M

G

FL

D

230 V - 50 Hz

L1

PE

N

2

L1

PE

N

1

C C CNC NC NO

1.3 (T.S.)

1.2 (P. min.)1.1 (P. max.)

SAFE

1

NPEL1

Menu

L

N

SS

M

Ext. MinDPIn

0-10V

P.

mod.

D

230 V - 50 Hz

L1

PE

N

2

L1

PE

N

1

NPEL1

Menu

+ 24 V

(-)

eBUS +

1

2

3

4

1

2

3

4

5

6

7

Menu

678910 11 12 FL TA

INAIL

Y2-BCM

12345

1

Y3- BCM

Y2-HSCP/UFLY

56

843

Y1-BMM1

4321

Y4- BCM

23

eBUS -

eBUS +

FL

1

C C CNC NC NO

1.3 (T.S.)

1.2 (P. min.)1.1 (P. max.)

SAFE

L

N

SS

M

Ext. MinDPIn

0-10V

P.

mod.

678910 11 12 FL TA

INAIL

Y2- BCM

12345

1

Y3- BCM

Y2-HSCP/UFLY

56

843

Y1-BMM1

4321

Y4- BCM

23

eBUS -

eBUS +

B

B

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

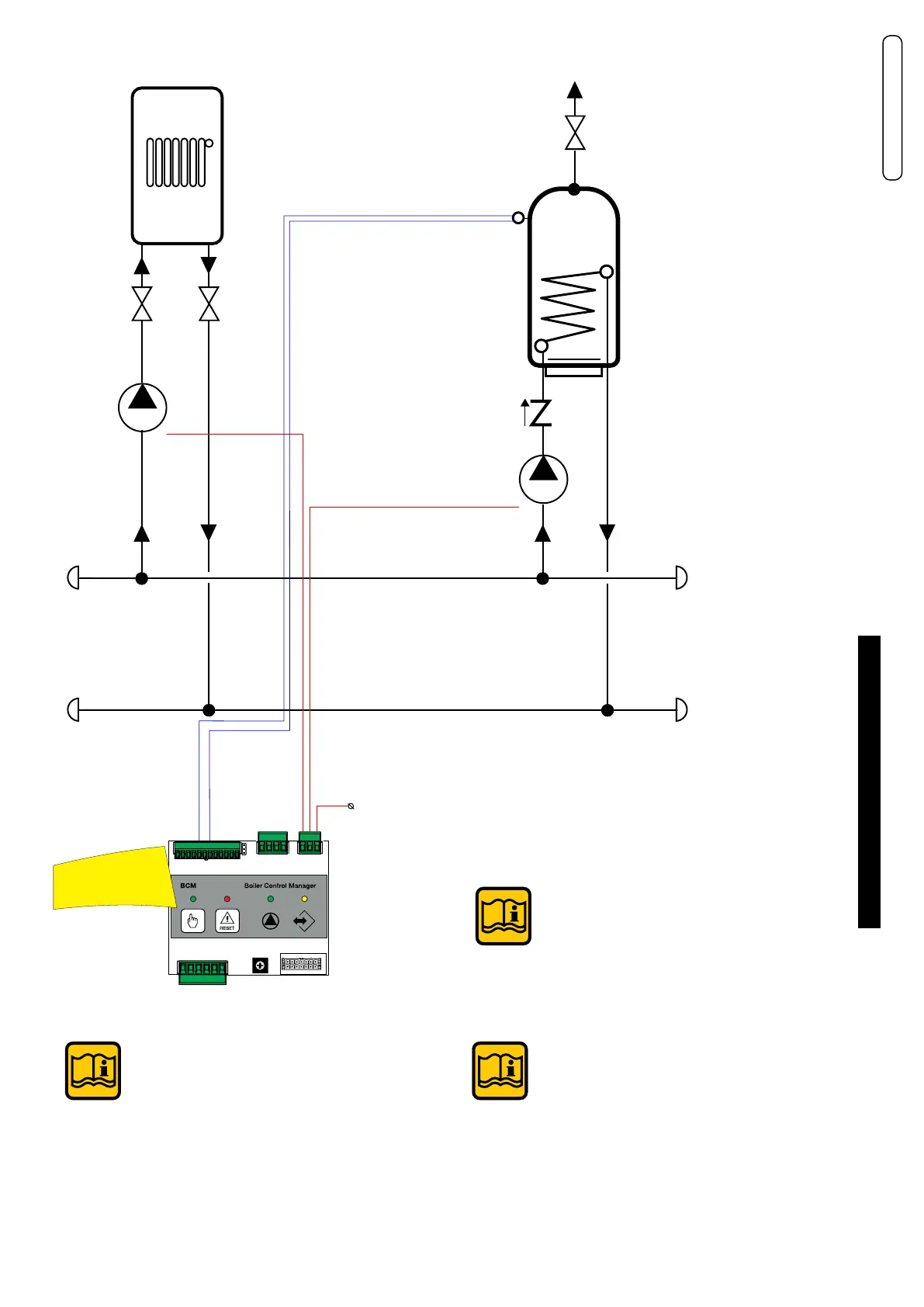

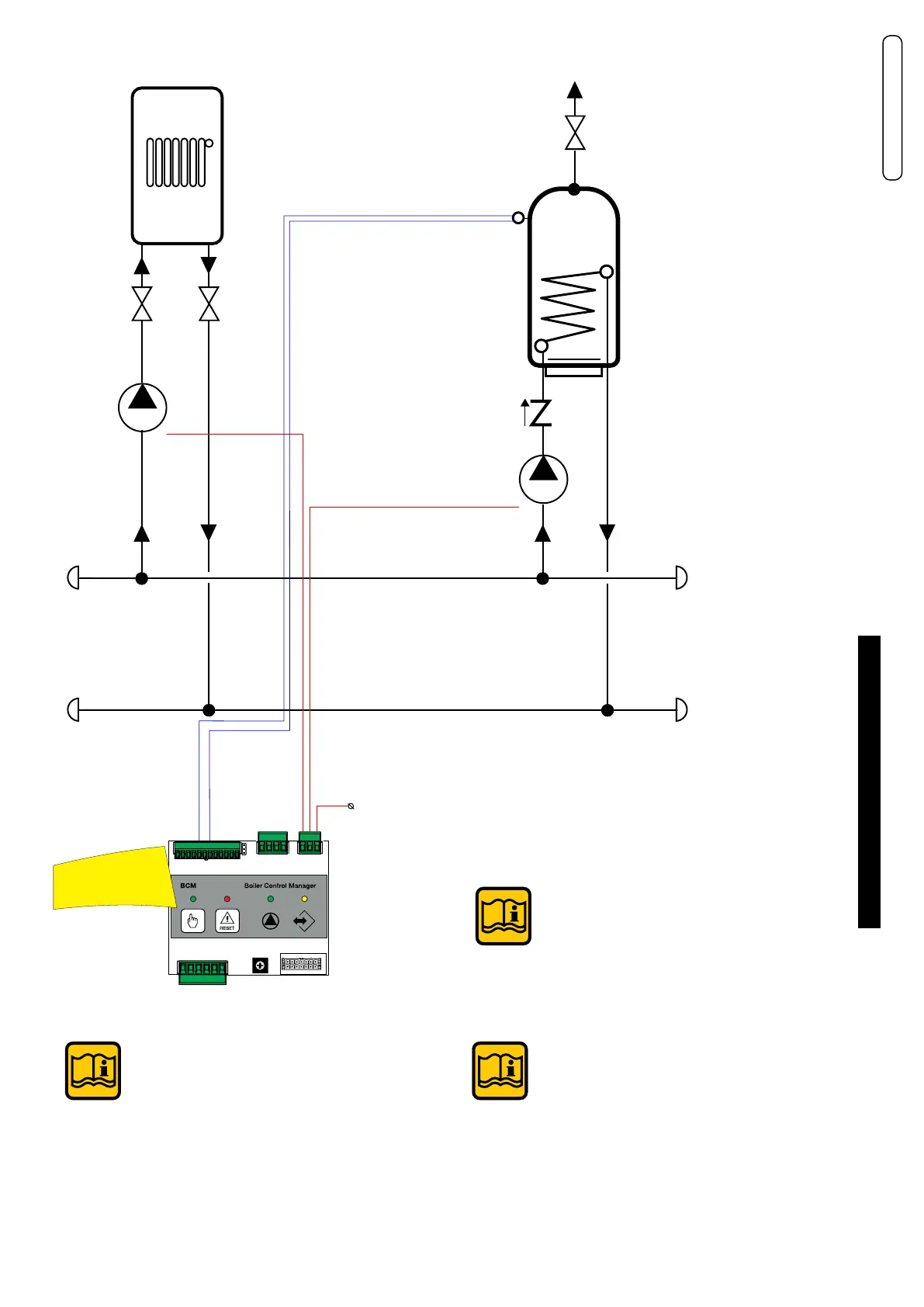

with direct zone and DHW production.

secondary loop

Note:

In case of installation with single boiler, the above

connections must be made on the return

terminal board (BCM board) inside the boiler.

Note:

To congure cascade boiler management param-

eters, refer to the specic installation manual.

Note:

Illustrative diagram, consider the total nominal

ow rate, any check valves (not supplied), and

verify the eciency of the ow switches at each

ow rate in modulation.

Loading...

Loading...