38

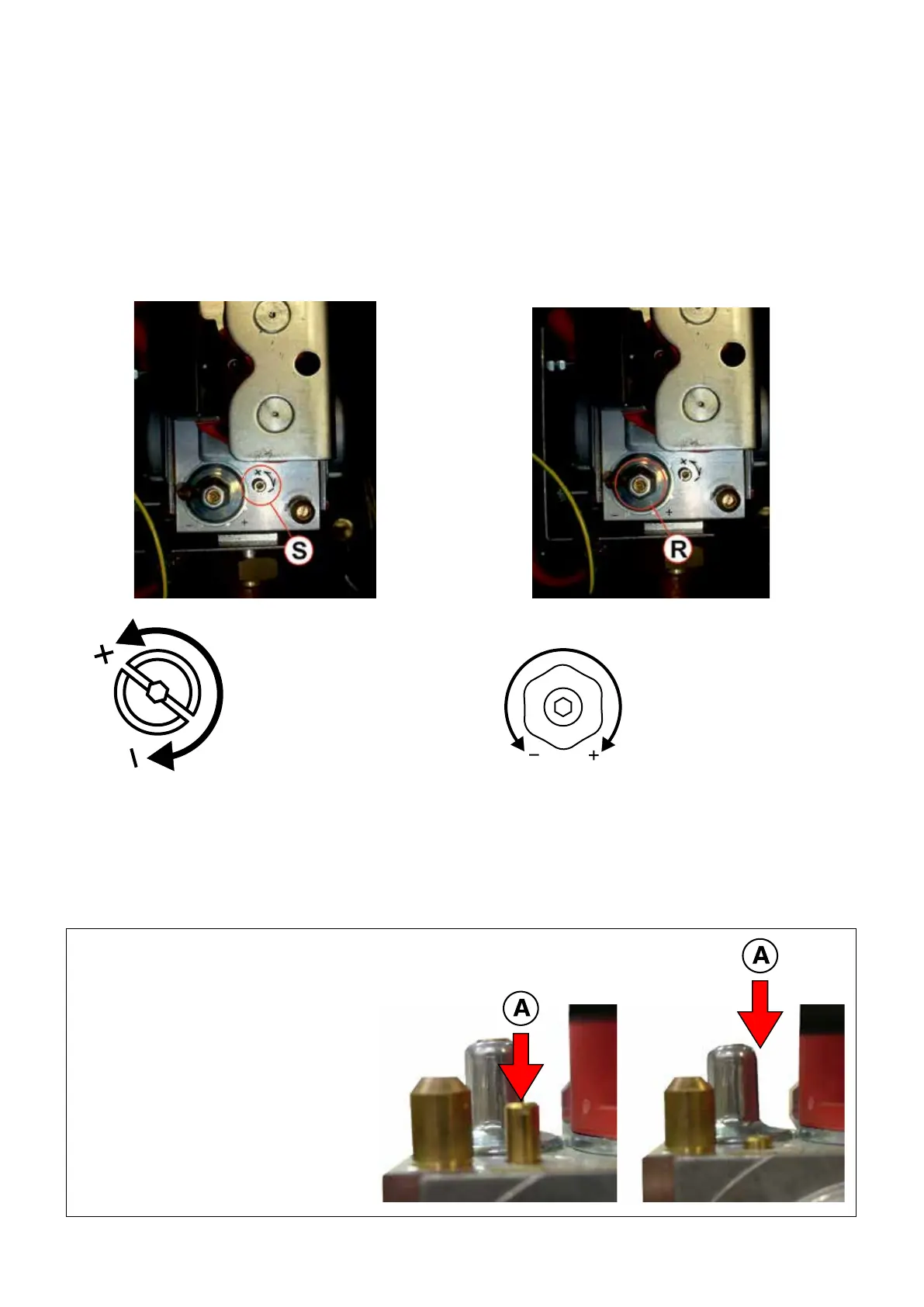

(S)

ADJUSTMENT SCREW

MAXIMUM OUTPUT

(R)

ADJUSTMENT SCREW

MINIMUM OUTPUT

- Remove the cap and insert the CO2 analysis sensor in the

ue gas sample point of the intake/exhaust terminal, see

chap. 3.12.2.

2) Minimum output adjustment

- Operate the boiler in “calibration” mode at MINIMUM OUTPUT

(see 3.12.1)

- Once the burner is on, check that the “MINIMUM” CO2 output

value corresponds to what is indicated in the “NOZZLES -

PRESSURE” table.

- If necessary, adjust the value by turning (with a 2.5 mm hex

key) screw “R” CLOCKWISE to increase it, ANTICLOCK-

WISE to decrease it

(see NOZZLES-CAPACITY-PRESSURE table).

1) Maximum output adjustment

- Operate the boiler in “calibration” mode at MAXIMUM OUT-

PUT (see 3.12.1)

- Once the burner is on, check

that the “MAXIMUM” CO2 output value corresponds to that

indicated in the “NOZZLES - PRESSURE” table.

- If necessary, adjust the value by turning the ‘’S’’ adjustment

screw CLOCKWISE to decrease it and ANTICLOCKWISE

to increase it

(see NOZZLES-CAPACITY-PRESSURE table).

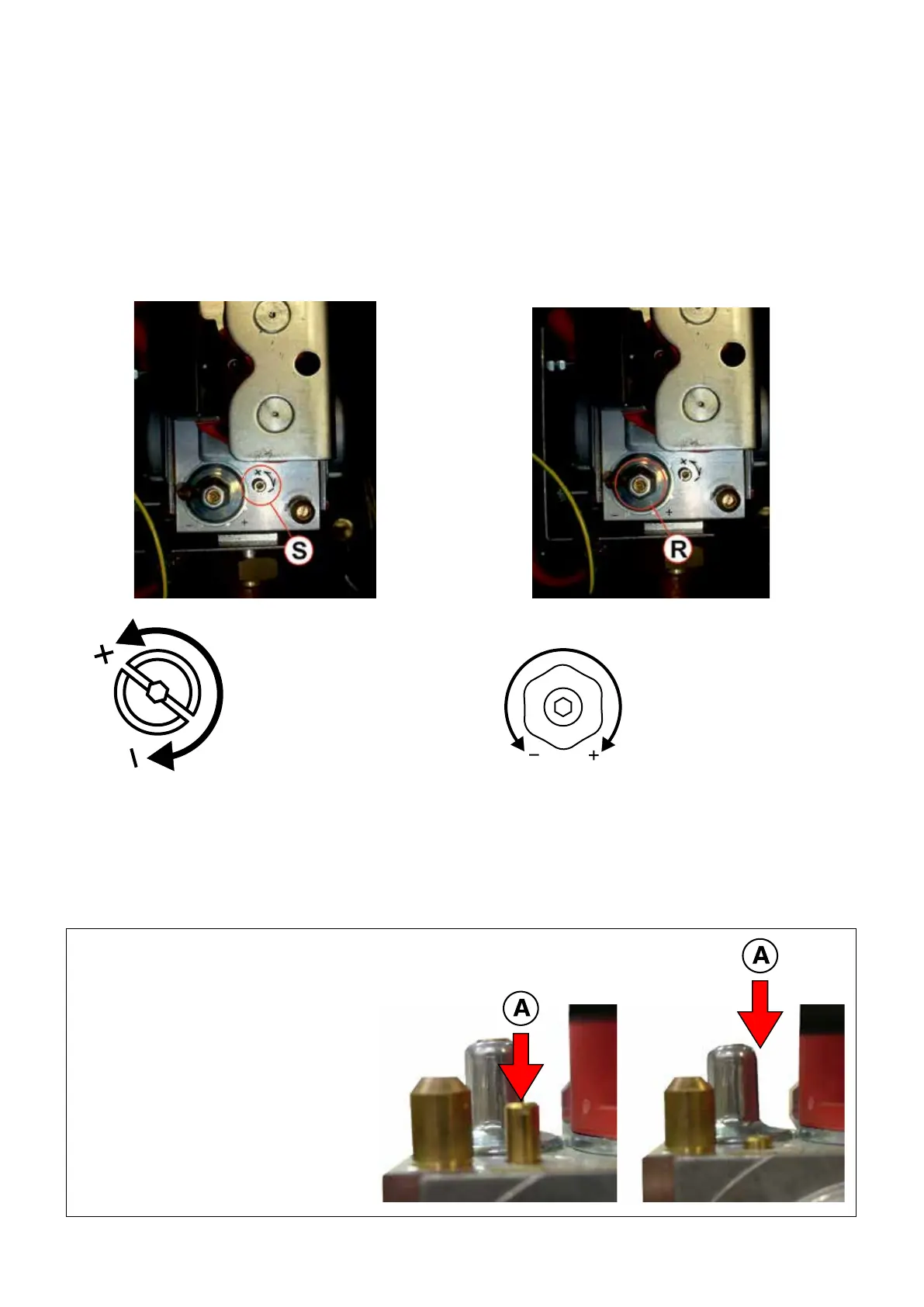

In case of replacement of the Gas valve or

ignition diculties:

Tighten the maximum adjustment screw ”A”

clockwise up to the stop, then loosen by 7 turns.

Check the boiler ignition, in case of a block,

loosen the screw “A” again by one turn, then try

igniting it again. If the boiler still stops running,

perform the above operations again until the

boiler ignites.

Now adjust the burner as previously illustrated.

Loading...

Loading...