46

We recommend having qualified technical

personnel carry out the provisions of current

regulation concerning periodic maintenance

checks.

Since the dust is vacuumed inside, the ue gas side resistance,

through the boiler, increases which, eventually, will lead to a

reduction of the thermal load (and, consequently, of the power).

Before cleaning, check the thermal load (see 3.13) and the

CO

2

percentage (see 3.13). If the read load (with correct CO

2

)

is around 5% of the indicated value, the boiler does not need

to be cleaned.

Therefore, the operation can be limited to cleaning the siphon

ATTENTION!

A drop in thermal load may be caused by the

obstruction of the exhaust duct or of the air inlet

duct. Firstly check that this is not the cause.

If a load reduction is detected of more than 5%,

check the cleanliness of the condensate collec-

tion pan and of the burner. Clean the siphon also.

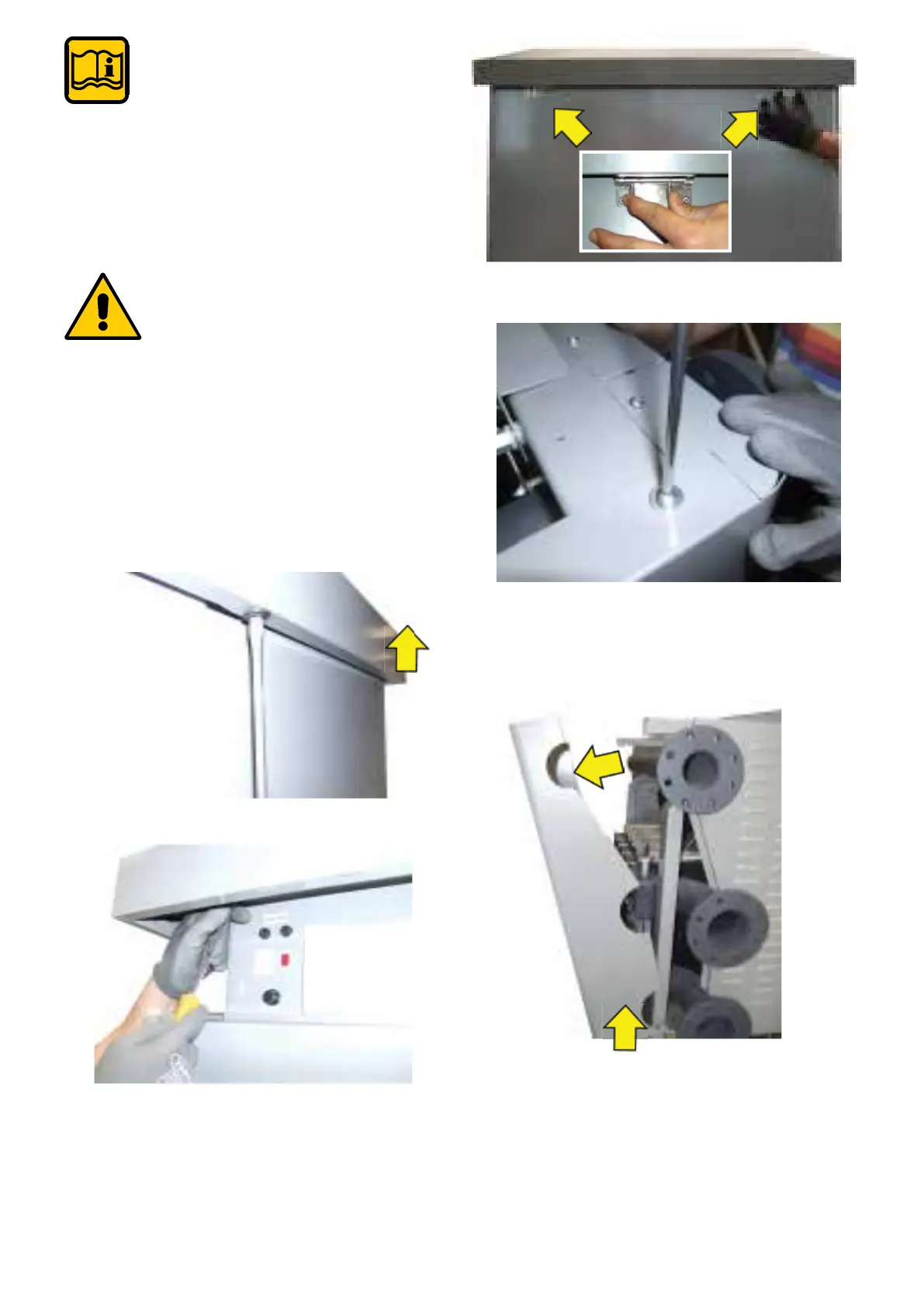

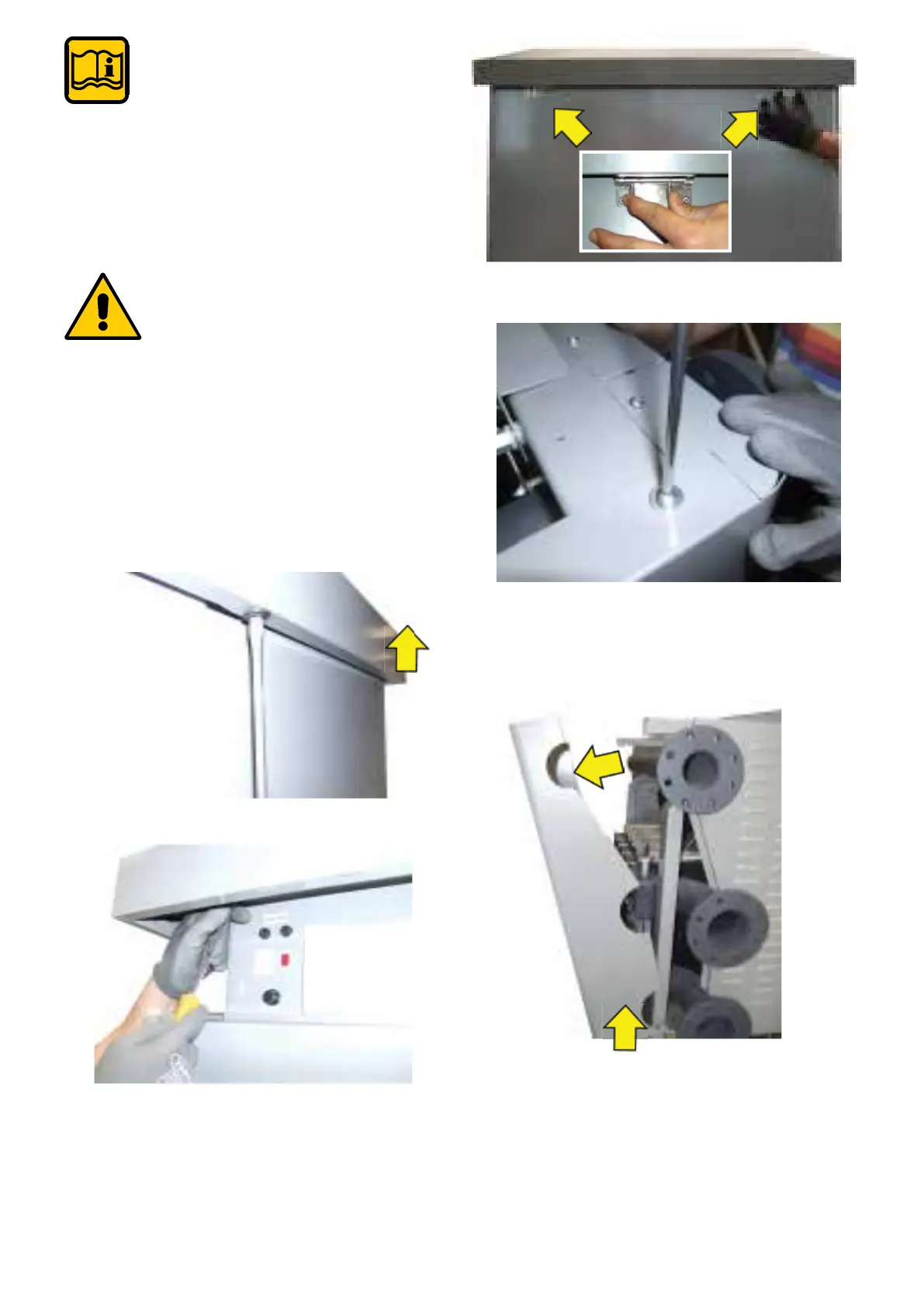

- Act on the two rear closing hinges to remove the cover

- Remove the casing fastening screws, rear, front and lateral.

- all casings

First phase – Disassembly

• Close the power and gas supply ensuring that the valve is

closed properly.

• Remove:

- Turn the indicated screw to lift the cover

- Remove the 2 cover fastening screws

Loading...

Loading...