Bulletin 30-20 — Page 11

© Copyright 2010, Unico, Inc.

minate the secondary drain line above a windowsill so

that the drainage splashes on the window. This will serve

as an indicator that there is a problem with the primary

drain. In cases where a secondary drain line cannot be

run, add a float switch or a micro switch with a paper

fuse.

Refrigerant Coil Connections

Note

All refrigerant coils are shipped from

our factory pressurized with nitrogen.

They do not contain any refrigerant.

WARNING

To prevent injury to eyes, face away

from the Schrader valve when releasing

nitrogen gas.

The refrigerant coils are equipped with a Schrader valve

port to relieve the pressure and for factory testing pur-

poses. It can also be used to check for leaks prior to in-

stallation. Unscrew the Schrader cap and press the de-

pressor. If there is no nitrogen pressure present, the

coil may have developed a leak during shipment and

should be returned to the point of purchase for ex-

change. If pressure is present, then go ahead and relieve

the pressure in the coil be continuing to press on the de-

pressor. When all the pressure is removed cut the ends of

the connections off.

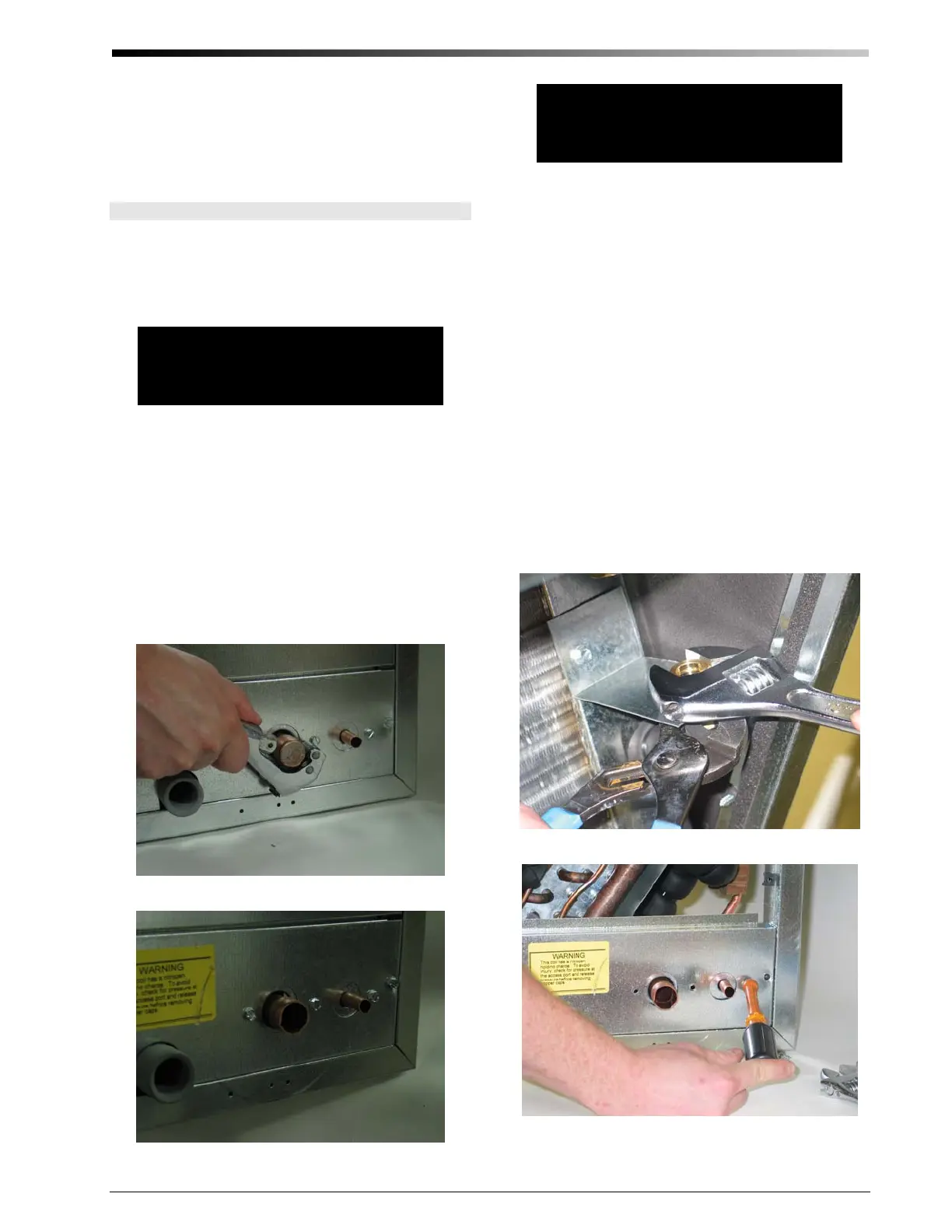

Cut end of connection as shown.

Connection after the end has been cut off.

WARNING

To prevent injury, remove all pressure

from coil before removing connection

end caps.

CAUTION

When brazing, purge with nitrogen gas

to prevent the formation of oxides.

The refrigerant lines are copper sweat connections. The

liquid line is 3/8-inch (9.5mm) OD and the suction line

is 7/8-inch (22mm) OD. Refer to the condensing unit

manufacturer’s instruction for proper line sizing infor-

mation based on distance from condenser.

Install a liquid line filter drier as close to the coil module

as possible to protect the evaporator from foreign object

debris. For attic installations or when using long line

sets, an optional moisture indicating sight glass should

also be installed between the filter-drier and expansion

valve, near the indoor unit.

All refrigerant coils require a thermostatic expansion

valve. The valve is shipped loose and should be attached

prior to charging. If the system will be using R-410a, be

sure to use the R-410a valve; these can be ordered sepa-

rately as shown in Table 6. Always use new Teflon seals

when replacing the TXV (Unico Part No. A00809-001).

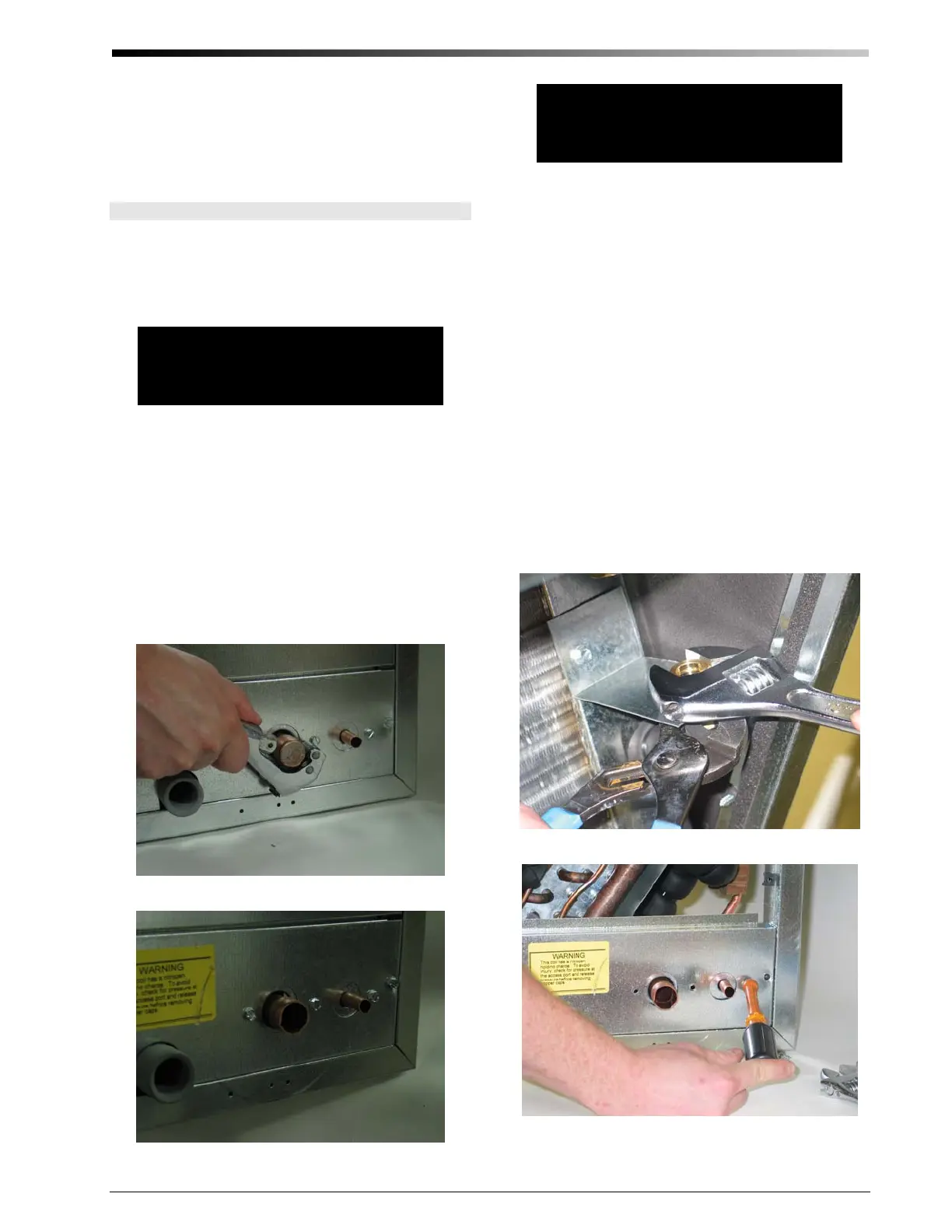

Remove nut as shown.

Remove side panels as shown.

Loading...

Loading...