Bulletin 30-20 — Page 10

© Copyright 2010, Unico, Inc.

Return Duct

Unico supplies a return duct system but any return duct

system is acceptable provided the pressure loss does not

exceed 0.15 inches of water (37 Pa), including filters.

The return duct should have at least one 90° bend be-

tween the unit and filter box to reduce sound transmis-

sion directly from the unit.

The Unico Return Duct system has a single return that

includes the return air box with filter, the return duct,

and the return air adapter (refer to Fig. 3). Multiple re-

turns or extra long returns are possible so long as the

maximum pressure loss is not exceeded. For vertical

installations or tight spaces it may be necessary to fabri-

cate a return duct system from duct board or lined metal.

The typical return duct is 10-foot (3 m) in length so it

may have to be cut to avoid bunching if the distance to

the unit is significantly less than 100-inches. The mini-

mum length should be 7-feet (2 m). When given a

choice, the shorter distances should be avoided as this

may increase sound transmission from the unit.

Cut an opening for the return box as specified in Table 1.

For the 2430 and 3642 if the joists or studs are on 16-

inch (410mm) centers, there is no need to build a frame

to hold the return air box. Otherwise, it will be necessary

to construct a frame around the opening. For the 4860

return, it will almost always be necessary to cut and

header at least one joist.

Center the return air box so the filter frame flange covers

all the gaps and make sure the flange is flush against the

wall or ceiling. Install the return air box against the

frame using nails or screws.

Screw holes are provided in the return air box. Use the

holes nearest the corners. The other holes are for mount-

ing the filter grille. See Fig. 14.

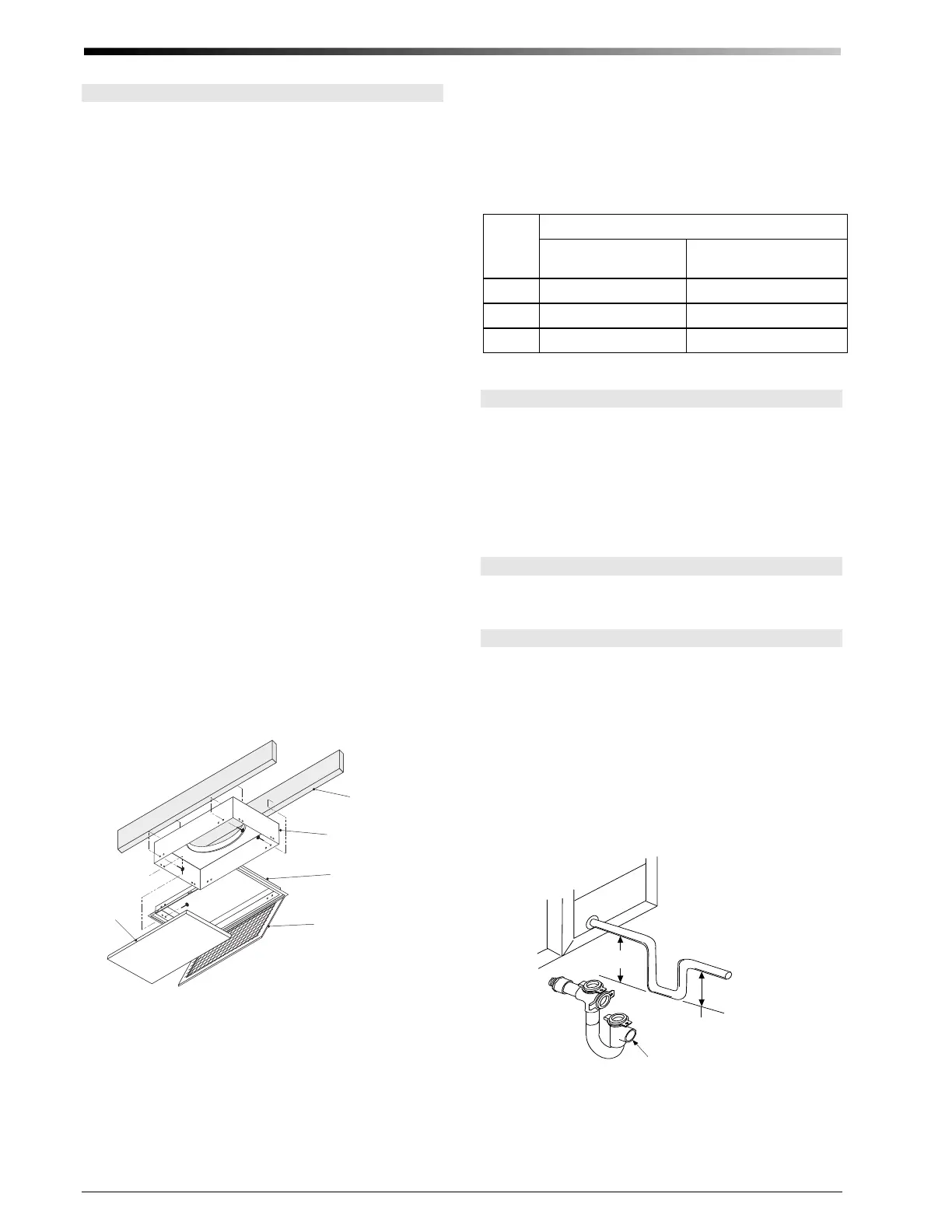

FRAMING

RETURN AIR BOX

FILTER FRAME

FILTER

FILTER GRILLE

IL00048.CNV

Figure 14. Return Air Box and Filter

Install filter frame into the return air box using four nails

or screws. Use the holes furthest from the corners. Insert

filter and hold in place by rotating metal clips. Close

grille and secure with clips.

Refer to Table 5 for correct Return Duct Adapter selec-

tion. Attach the proper return duct adapter to either the

Heating or Cooling Module. Then attach the return duct

to the adapter and to the return air box using the Q-bands

and Q-clips.

The return air adapter ships with an insulation blanket

that must be wrapped around the adapter. Tape the

seams with UL 181A aluminum tape.

Table 5. Return Duct Adapter

Unit Size

Blower Module +

Cooling Module

Heating Module

+ Cooling Module

4860 UPC-59-4860 UPC-104-4860

3642 UPC-59-3642 UPC-104-3642

2430 UPC-59-2430 UPC-104-2430

Multiple Returns

If more than one return is desired, Unico has designed a

return plenum (MR) module. The MR module is availa-

ble in two sizes: 2430 and 3660, and it includes a central

filter. The MR module is easily fitted to the air handling

unit and multiple return openings may be cut in the top

back or sides of the box. Refer to Bulletin 20-20.6, Re-

turn Plenum Module, for additional information.

PIPING

All piping must be in accordance with all local codes

and ordinances.

Condensate Lines

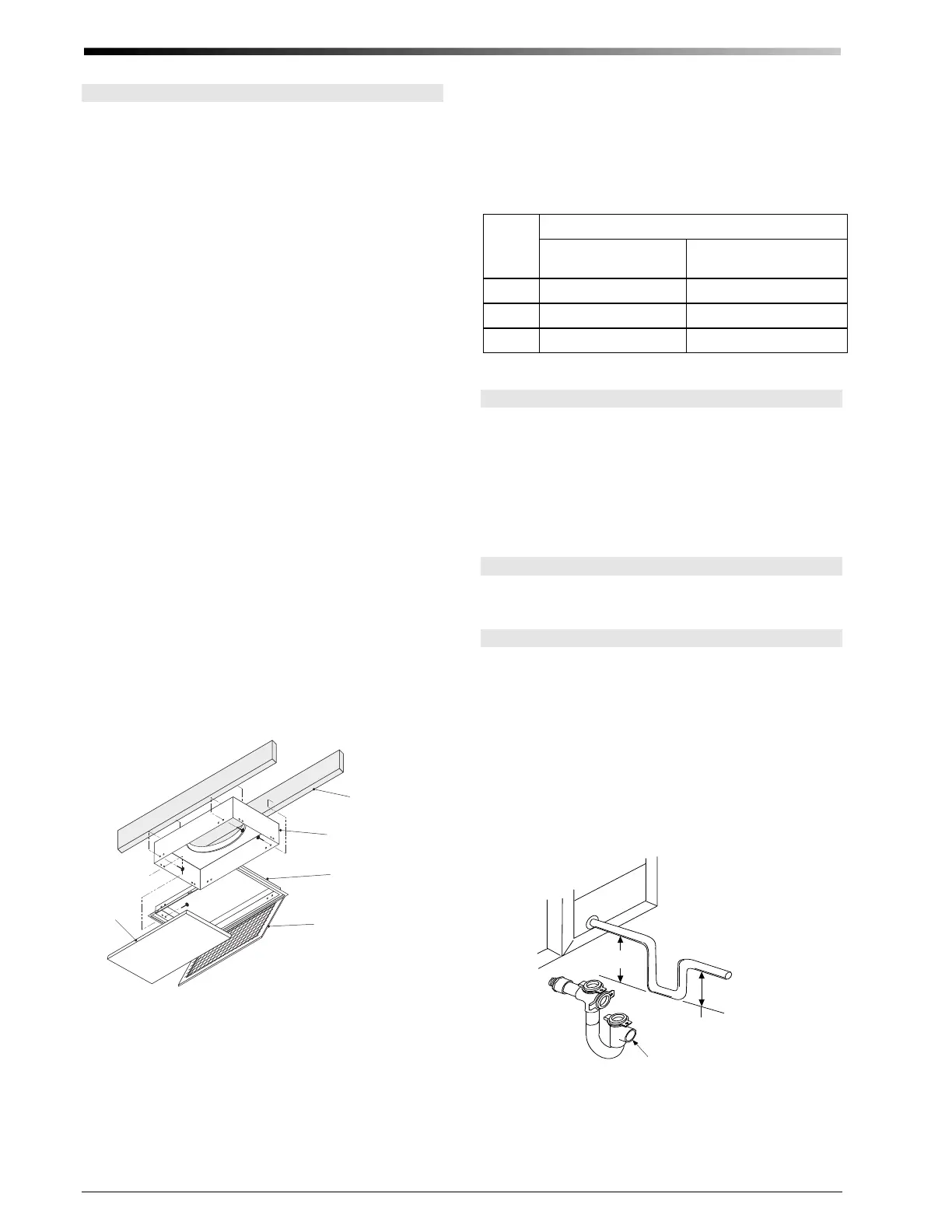

The primary drain pan condensate connection is a ¾-

inch (19mm) female pipe thread fitting and the second-

ary drain pan connection is a ¾-inch (19mm) PVC sock-

et fitting. Elevate the unit so the condensate lines are

pitched at least ¼-inch per lineal foot (20 mm per me-

ter). Trap the condensate line near the unit using U-trap

A00924-G03 as shown in Figure 15. In some cases it

may be necessary to wrap the condensate line near the

unit with insulation to prevent water condensation on the

outside of the pipe. In some climates or locations it may

be necessary to protect trap from freezing in the winter.

53/8

(137 mm)

21/4

(57 mm)

Pitch ¼ inch per foot

(2 cm per m)

IL00046a.cvx

U-TRAP (A00924-G03)

shi

ed wi

h MC modules

Figure 15. Typical Condensate Trap

Do not trap the secondary drain line and do not terminate

line into the primary drain line. Run secondary drain line

so that any drainage will be immediately known without

causing damage to property. A typical location is to ter-

Loading...

Loading...