Bulletin 30-20 — Page 9

© Copyright 2010, Unico, Inc.

DUCT CONNECTIONS

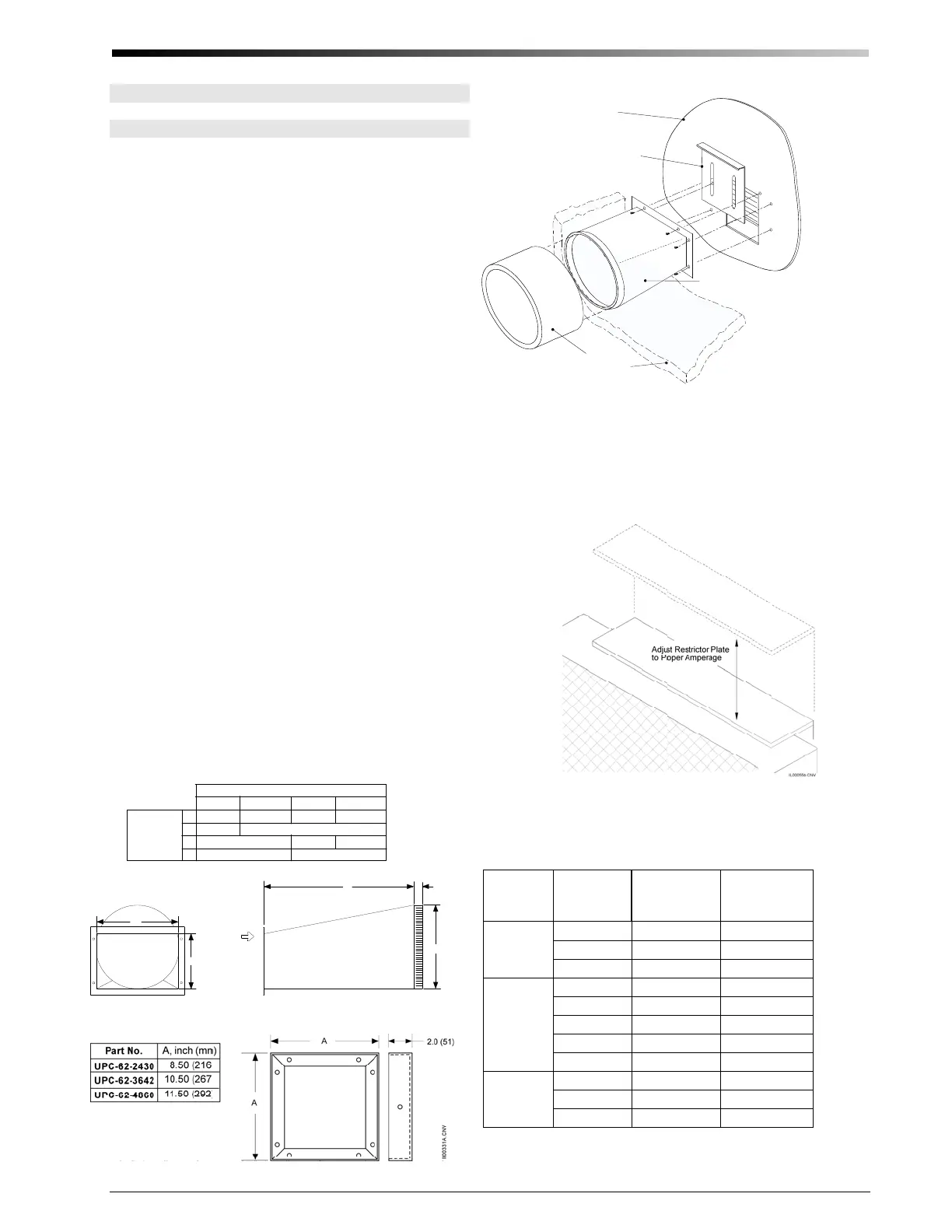

Supply Plenum

Unico has a complete line of round and square plenum

adapters available as shown in figures 10 and 11. In

addition, all blowers include a restrictor plate to be in-

stalled between the supply adapter and the unit. The

purpose of the restrictor plate is to eliminate objectiona-

ble outlet noise because the blower is delivering more

air than required. In most cases where the maximum

airflow is required, the restrictor may be omitted.

To attach the plenum adapter, first install the restrictor

plate. Then install the adapter with eight (8) sheet metal

screws as shown in Fig. 12. Sheet metal screws for in-

stalling both are provided with the blower.

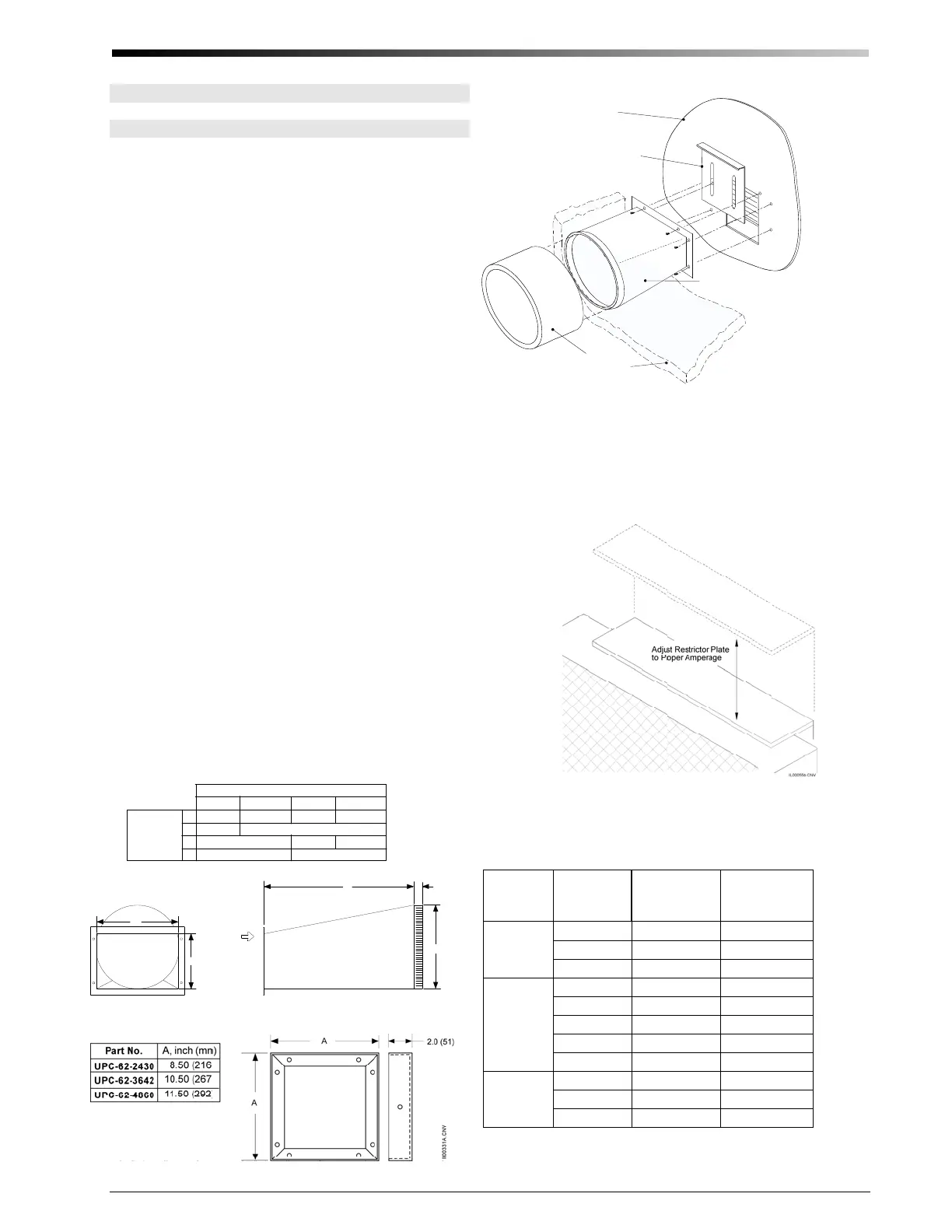

The restrictor plate is used to set the system airflow (see

Fig. 13). The full open position corresponds to the high-

est airflow the installed duct system will allow. Set the

restrictor plate to the full open position and measure the

system airflow. The required system airflow is 200-250

CFM per nominal ton (27-34 L/s per nominal kW).

Measure the motor amperage and use this to ensure the

200-250 CFM per nominal ton (27-34 L/s per nominal

kW) has been achieved. If elevated sound levels are no-

ticed at the outlets and there is more that 250 CFM per

nominal ton (34 L/s per nominal kW), the airflow may

be reduced with the restrictor plate. Always measure the

system airflow by the motor amperage (see Table 4).

Refer to the airflow-amperage charts provided with the

blower.

Note: Do not use restrictor plate to adjust

plenum static pressure. Adjust the restrictor

to the proper amperage. This will assure

proper airflow.

Attach the plenum to the adapter by inserting it over the

supply adapter. If using sheet metal duct, use three (3) or

four (4) equally spaced sheet metal screws or nails to

secure the duct to the supply adapter. Then tape around

the seam with UL 181A aluminum tape. Then wrap the

outside of the plenum adapter with the supplied blanket

insulation and secure the insulation seams with UL 181A

tape.

Figure 13. Restrictor Setting

Blower

Module

Restrictor

Plate

Plenum Adapter

Plenum

Insulation Wrap

IL00308.CVX

Figure 12. Supply Plenum Adapter Installation

Table 4. Approximate Amperages at Given Airflows

Unit Size

Airflow,

CFM (L/s)

MBxxxxL

Amps

@230V †*

MBxxxxL+CB

Amps

@230V †

4860

1250 (590)

4.1 4.1

1000 (470) 3.5 3.3

800 (380) 3.1 2.8

3642

1000 (470) 3.9 3.7

900 (420) 3.6 3.4

800 (380) 3.2 3.2

700 (330) 3.0 2.9

600 (280)

2.8 2.7

2430

600 (280)

2.2 1.9

500 (240)

2.0 1.6

400 (190)

1.8 1.4

* multiply by 1.1 if 208V

† for more exact airflow use the chart included with the blower

B

A

D

L

1 (25)

crimped

I

L

0

0

2

8

6

.

c

n

v

AIRFLOW

Model, UPC-61-

1218

2430

10 (254)

3642

4860

7.16 (182)

10.13 (257)

18 (457)

9 (229)

A

B

Dimension,

inch (mm)

6.5 (165)

6 (152)

3.25 (83)

6.38 (162)

D

L

7 (178)

12 (305)

Figure 10. Round Supply Plenum Adapter Dimensions

Figure 11. Square Supply Plenum Adapters

Loading...

Loading...