Bulletin 30-20 — Page 2

© Copyright 2010, Unico, Inc.

Each module is available in three sizes: 2430, 3642, and

4860. Models with a 3660 model number denote that the

particular unit piece may be used with the 3642 or 4860

model.

There are three basic modules: a blower module, a cool-

ing module, and a heating module. The blower module

includes the blower wheel, blower housing, motor, and

electrical control box. The cooling module includes a

cooling-only refrigerant coil, a heat pump coil, or a

chilled water coil. The heating module is supplied as an

empty cabinet with room for a slide-in hot water coil.

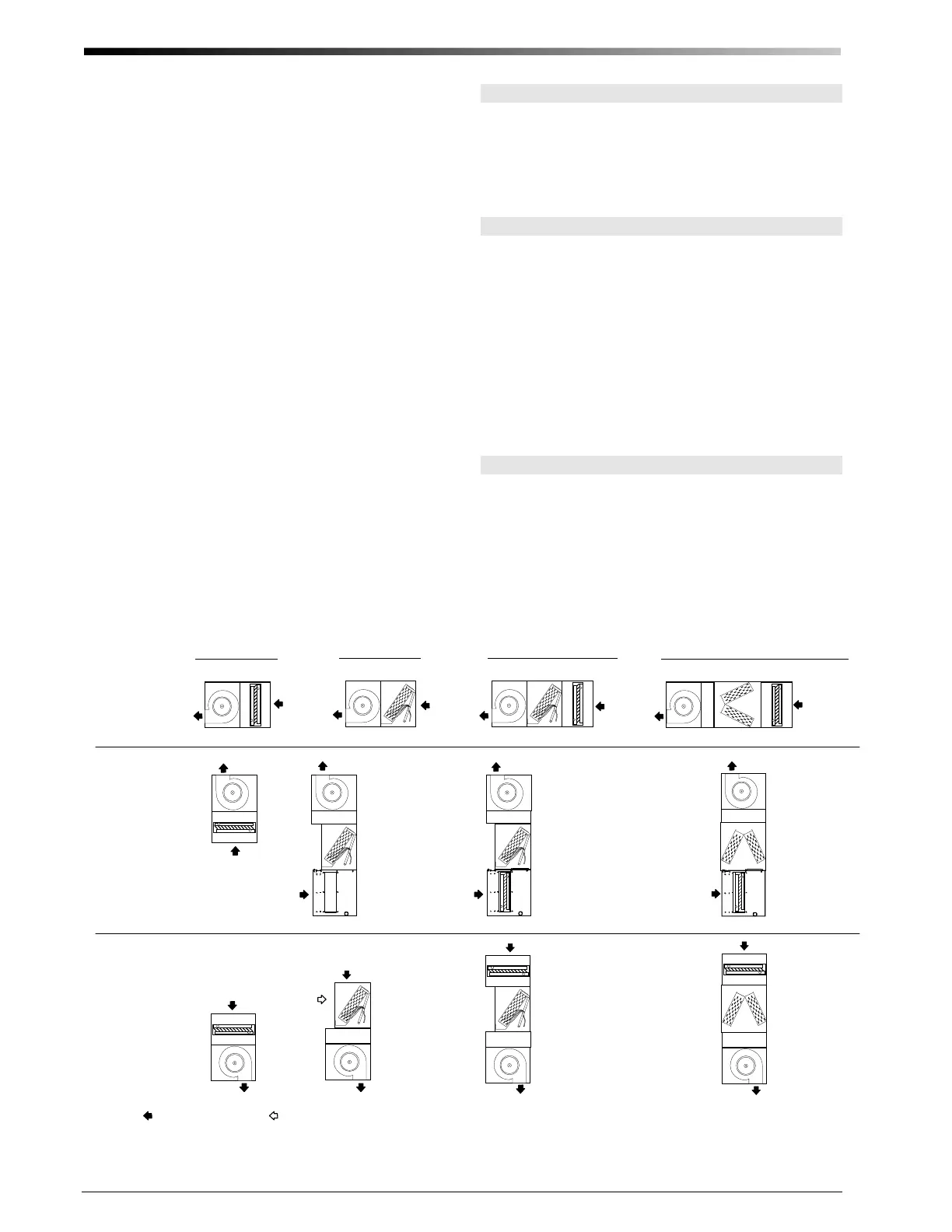

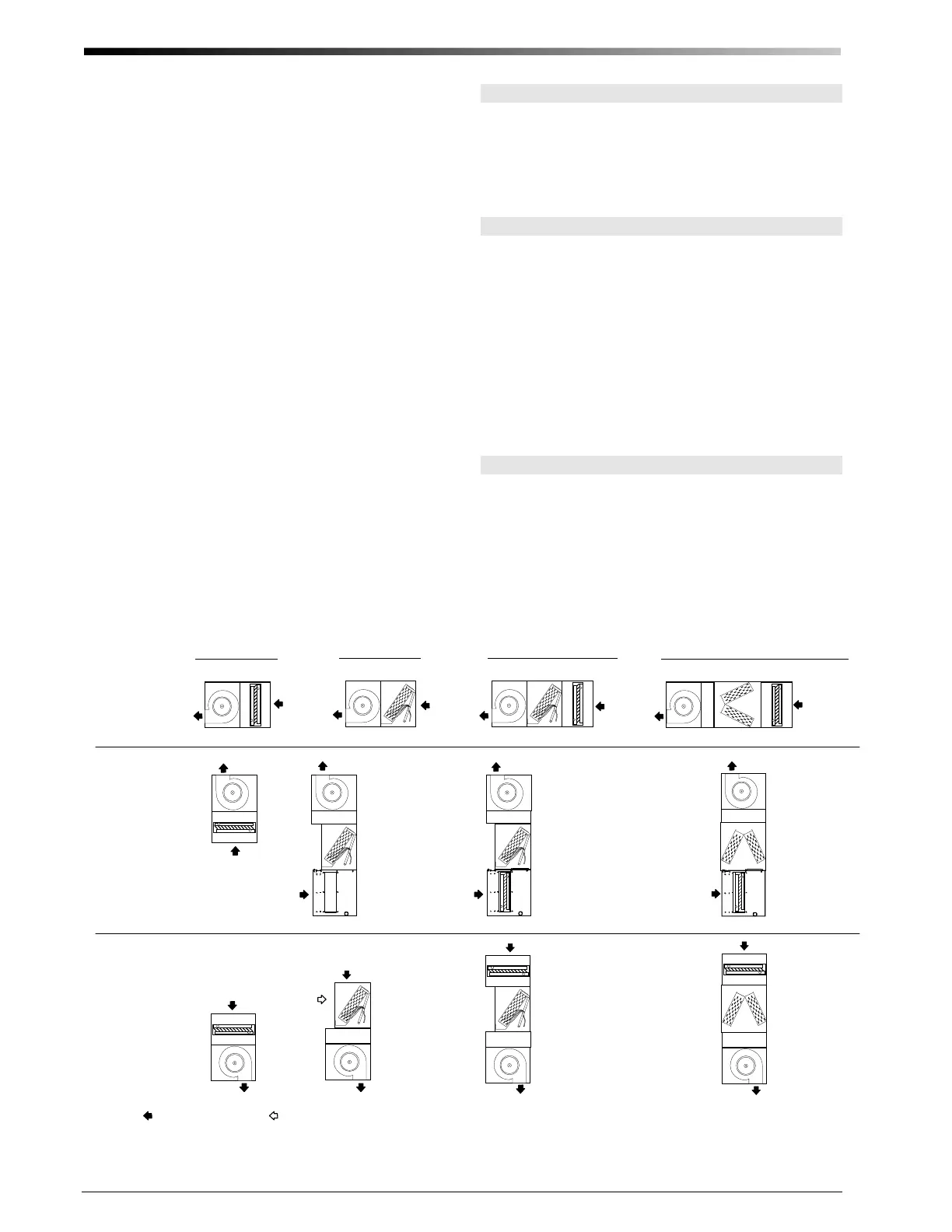

The modules can be arranged to provide only the options

needed as shown in Figure 1 (with details on pages 26

and 27). Heating-only systems require the blower

module, the heating module, and a hot water coil. Cool-

ing-only systems include the blower module and a cool-

ing module. For heating and cooling all the modules are

combined with coils. The system may even be used for

ventilation-only, using just the blower module.

Unico designed and built blowers feature direct drive

motors or EC motors and are located in the air stream.

Each blower wheel is balanced to Unico specifications.

The blowers feature a quick twist-and-lock motor mount

for easy maintenance (see page 16). The motorized

blower assembly consists of the motor, which is

mounted to the inlet ring, and the wheel, which is

mounted to the motor shaft.

OPTIONS

Other options and modules are also available to add ad-

ditional features or to simplify installation. These in-

clude an electric duct heater, multiple return plenum, and

a vertical plenum stand. Please refer to the latest Unico

Catalog for information on these and other options.

UNPACKING

All modules are inspected prior to shipping and are care-

fully packaged in individual cartons. Inspect all cartons

prior to unpacking. Notify carrier of any damage.

Open each carton to remove the modules. Inspect unit

for visible signs of concealed damage and notify carrier

of any such damage.

All materials are sold FOB Factory and it is the respon-

sibility of the consignee to file any claims with the deli-

vering carrier for materials received in damaged condi-

tion.

LOCATION

Locate the air handler to minimize the number of plenum

elbows and fittings while keeping the supply duct runs as

short as possible. (See Bulletin 40-30, Component Duct

Layout Design). Provide minimum clearance on both

sides for servicing the unit as shown in Fig. 2.

Heating and Cooling

Horizontal

Flow

Vertical

Counter-Flow

Vertical

Up-Flow

IL00010d.CVN

Heating Only

Cooling Only

No

mal Ai

Inle

/

u

le

ional Ai

Inle

Blower Module`

Spacer Module

Cooling Module

Vertical Plenum

Module (with Hot

Water Coil)

Vertical Plenum

Module (without Hot

Water Coil)

Spacer Module

Heating Module

(with Hot Water Coil)

Heating and Cooling (M4860)

Figure 1. Basic Module Arrangement (refer to detail figures shown on Pages 26 and 27)

Loading...

Loading...