Bulletin 30-20 — Page 13

© Copyright 2010, Unico, Inc.

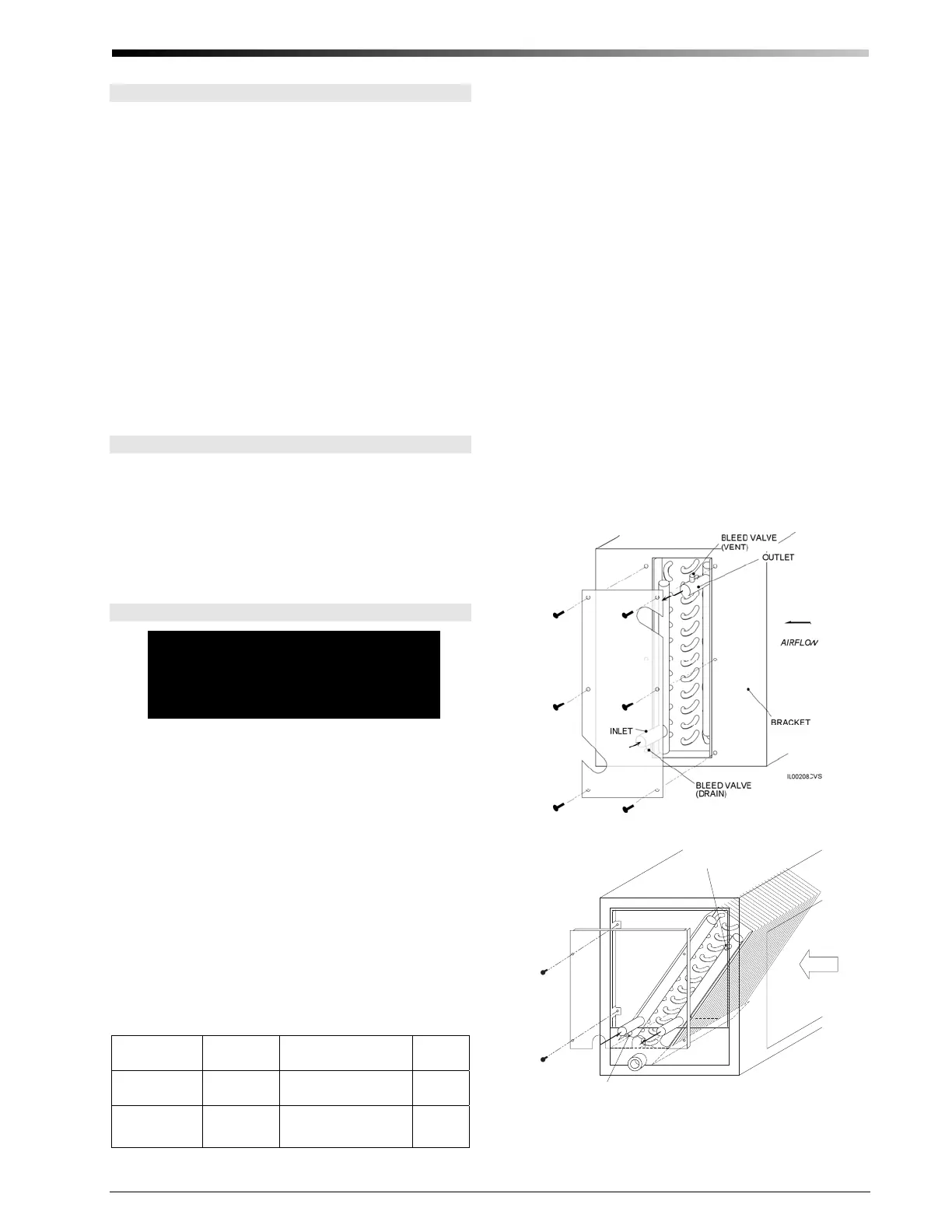

Water Connections

If you are installing the hot water coil, remove the side

coil access panel and cut away the insulation. Slide the

coil into the cabinet and secure with brackets supplied

with the hot water coil. Install the access panel after the

coil is in place.

All water connections are 7/8-inch (22mm) sweat con-

nections. Sweat the water connections, then fill the sys-

tem. Bleed the air from the coil by backing off the screw

inside the bleed valve for venting (Fig. 16).

If unit is in an unconditioned space below freezing, care

must be taken not to freeze the water in the coil. The best

method is to use a glycol-water antifreeze solution with a

freezing point below the coldest temperature expected.

After venting the chilled water coil, replace the access

panel and seal around the connections with the rubber

gasket provided.

Coil Cleaning

The coil should be sprayed with liquid detergent, or any

commercially available evaporator cleaner solution, tho-

roughly and rinsed thoroughly before installation to as-

sure proper drainage of condensate from the coil. This

will eliminate blowoff and assure maximum coil perfor-

mance. If not sprayed, approximately 50 hours of break-

in time are required to achieve the same results.

WIRING

WARNING

Disconnect electrical supply before

wiring unit to prevent injury or death

from electrical shock.

All electrical wiring must comply with all local codes

and ordinances. Blower module controls and compo-

nents are bonded for grounding to meet safety standards

UL Standard 1995 and CAN/CSA-C22.2 No. 236 and

are listed by ETL. All 50 Hz units are CE marked and

conform to the Low Voltage 73/23/EEC and EMC

89/336/EEC Directives.

Use a separate 1 ph - 230/208V – 60/50 Hz power

supply with a 15 amp breaker and appropriate wire

gauge per code.

Two different control boxes are available: one with a

variable ventilation speed control, one without. All stan-

dard units include a variable speed motor controller to

adjust the proper airflow for constant ventilation where

required by code or desired by the resident. The “ventila-

tion” speed is adjustable down to half airflow.

Control BoxMo-

del No.

Ventilation

Control

Availability

Wiring

Diagram

A00175-G02 Yes

Standard

(U.S., Canada)

Fig. 20

A00175-G03 No

Special Order

(Europe)

Fig. 21

The control box includes a 24-volt transformer, the ne-

cessary blower relays, and terminal blocks. Space is pro-

vided for a heat pump heating mode bypass relay

(shipped with heat pump cooling module). Space is also

provided for an additional double pole double throw

(DPDT) relay for wiring a boiler, pump, or valve if heat-

ing with hot water.

1. First, connect the motor plug to the wiring harness

from the control box.

2. Then, route the anti-frost switch lead wires (located

on the refrigerant coil) through the interior of the

modules to the control box. Connect the leads to

terminals #3 and #6 of the Low Voltage Terminal

Block. ALL DX COILS NEED THE FROST

SWITCH.

3. Next, connect the control wiring per figures 17

through 19. For units with electric duct heaters, refer

to Bulletin 30-34. Match thermostat anticipator set-

tings for combined amperage load of all compo-

nents, including electric heater contactors, to pre-

vent damage to thermostat.

4. Connect power supply to terminals L1 and L2 on

the high voltage terminal block. Connect a ground

(a) Hot Water Coil

BLEED VALVE

(VENT)

BLEED VALVE

(DRAIN)

IL00054b.CVN

IN

OUT

AIRFLOW

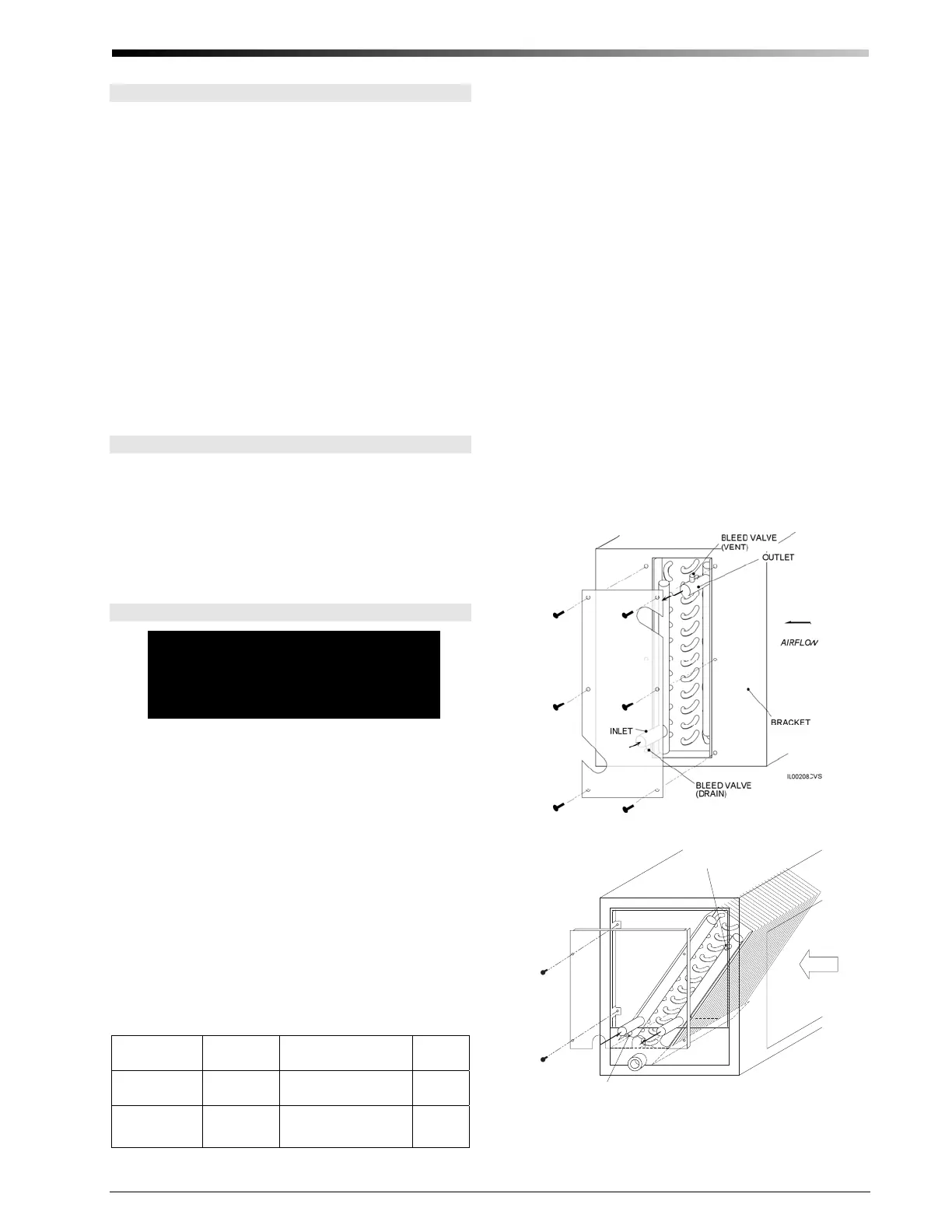

(b) Chilled Water Coil

Figure 16. Water Coil Connections

Loading...

Loading...