Bulletin 30-20 — Page 22

© Copyright 2010, Unico, Inc.

As a recommended further check on airflow, use a ve-

lometer to measure the airflow from each outlet. The

most convenient instrument to use is a hand held vane

type velocity meter that fits directly over the outlet. The

Turbo-Meter (Davis Instruments Catalog No. DS105I07)

or equivalent meter will give a direct LED readout on

the Knots (FPM x 100) setting, when multiplied by 2

gives the CFM of the outlet within an accuracy of 10%.

(Multiply ‘knots’ by 0.94 to obtain L/s.) Refer to Tech-

note 113 for more information.

By measuring and totaling the airflow of all outlets, the

total airflow of the system can be closely approximated

and provide a crosscheck for the airflow determined

from the motor amperage using the airflow-amperage

table that is shipped with the Blower module.

Note: These tables are for the specific mo-

tor installed in each blower module. Be

sure the table used applies to the correct

model number that is shown on the table.

Use Table 7 to correct the airflow.

Check Static Pressure Measure the external static

pressure (see the following section) in the supply plenum

at least two feet (610 mm) from the unit and verify that it

is within the allowable range.

With the restrictor plate positioned according to table 4,

the plenum static pressure should be 1.4 to 1.6 inches of

water column (350 to 400 Pa). If the plenum size is 9-

inch (229mm) diameter, the plenum static pressure will

be a little greater, about 1.8 inches of water column (450

Pa).

It is not necessary to measure the return duct static pres-

sure unless it was field fabricated. The maximum return

static pressure (including filters) should be 0.15 inches

of water (37 Pa). If it is greater than 0.15 inches of water

column, add the return system pressure drop to the

supply plenum static pressure to get the total static pres-

sure drop.

For example: If the supply static pressure is measured

to be 1.6 inches w.c. and the return system pressure drop

is 0.25 inches w.c, the total static pressure drop is: 1.6 +

0.25 = 1.85. In this case the static pressure is too high.

If the restrictor plate is not positioned according to Table

4, the static pressure reading is not an effective indicator

of airflow although it should still be recorded. In this

case, measuring motor amperage is the only reliable in-

dicator.

Check Motor Amperage. Remove the control box

cover and measure the current with an amp meter and

compare to the Motor Amperage-Airflow table enclosed

as a separate sheet in the Blower Module carton.

Check Outlet Airflow. Measure and record the air

flow from each outlet with a TurboMeter (refer to Tech

Note 113, How to Measure Outlet Airflow, for more in-

formation). Place the TurboMeter against each outlet,

centered as best possible and record the “knots”. Multip-

ly the knots by 2 to obtain CFM, then sum all the outlets.

The sum is the total airflow; this can be compared to the

outlet indicated by the amperage. A significant differ-

ence could indicate duct leakage.

How to Measure Static Pressure Measure the

supply plenum static pressure at least 18-inches

(457mm) from the unit, but before any tee or elbow. A

distance of between 2 and 3-feet (0.6 to 0.9m) is best.

Use an inclined manometer capable of reading at least

2.5 inches of water column (622 Pa), such as Dwyer

Instrument’s model 109 manometer. Be sure to zero the

scale and level the manometer.

A magnehelic gauge that measures up to at least 2.5

inches of water may also be used.

Use a metal tube, typically ¼-inch (6mm) diameter, to

measure the static pressure. Determine where you want it

and cut or punch a small hole in the duct. Make the hole

the same size as the metal tube to prevent leakage. Insert

the metal tube 1-inch (25mm) so that the tip of the tube

is flush to inside wall of the duct and perpendicular to

the air stream as shown in Fig. 26.

Attach the metal tube to the manometer using a rubber

hose (usually supplied with the manometer). Record the

pressure.

Note: If the tube is not perpendicular to the air stream,

the reading will be in error. You will get a higher reading if

the tube is angled toward the air stream.

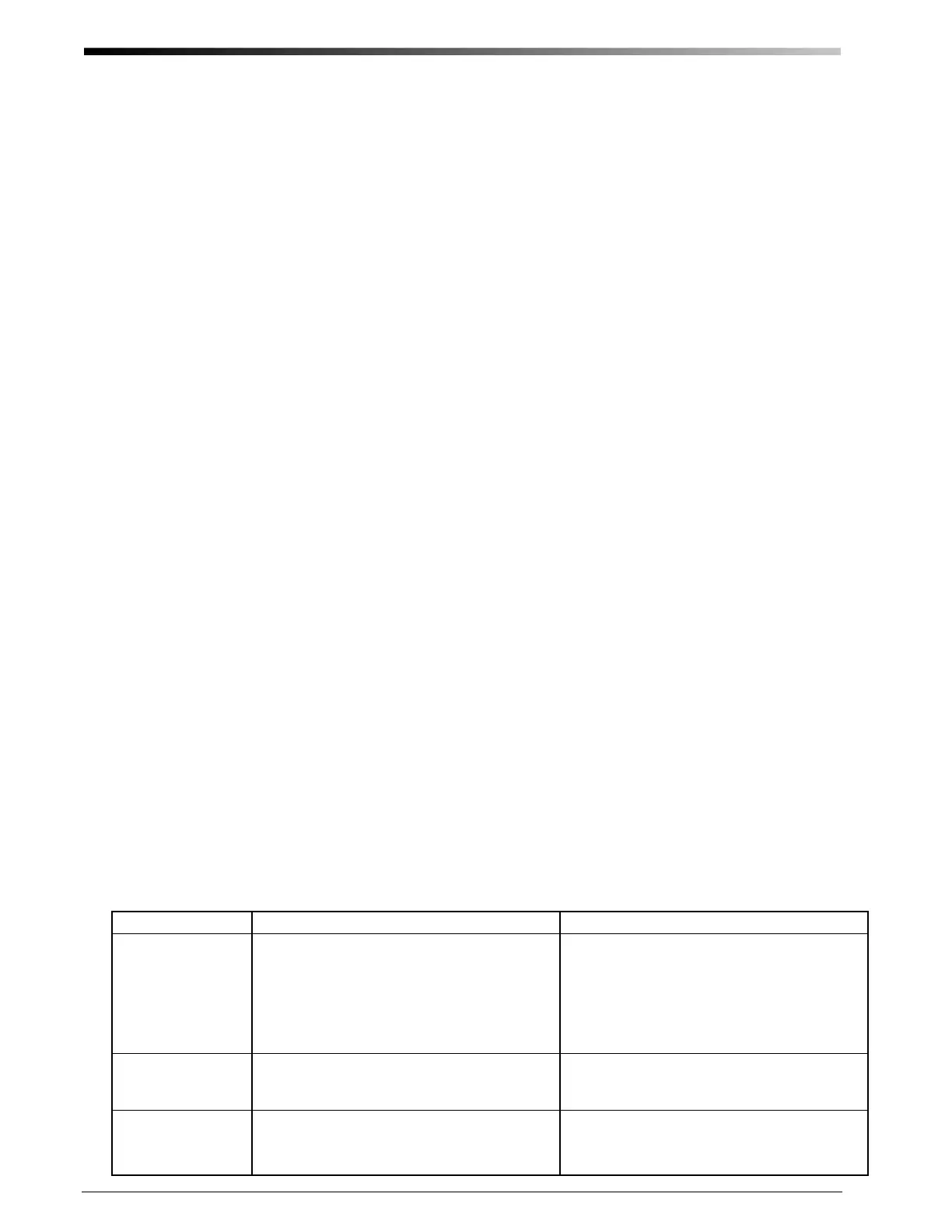

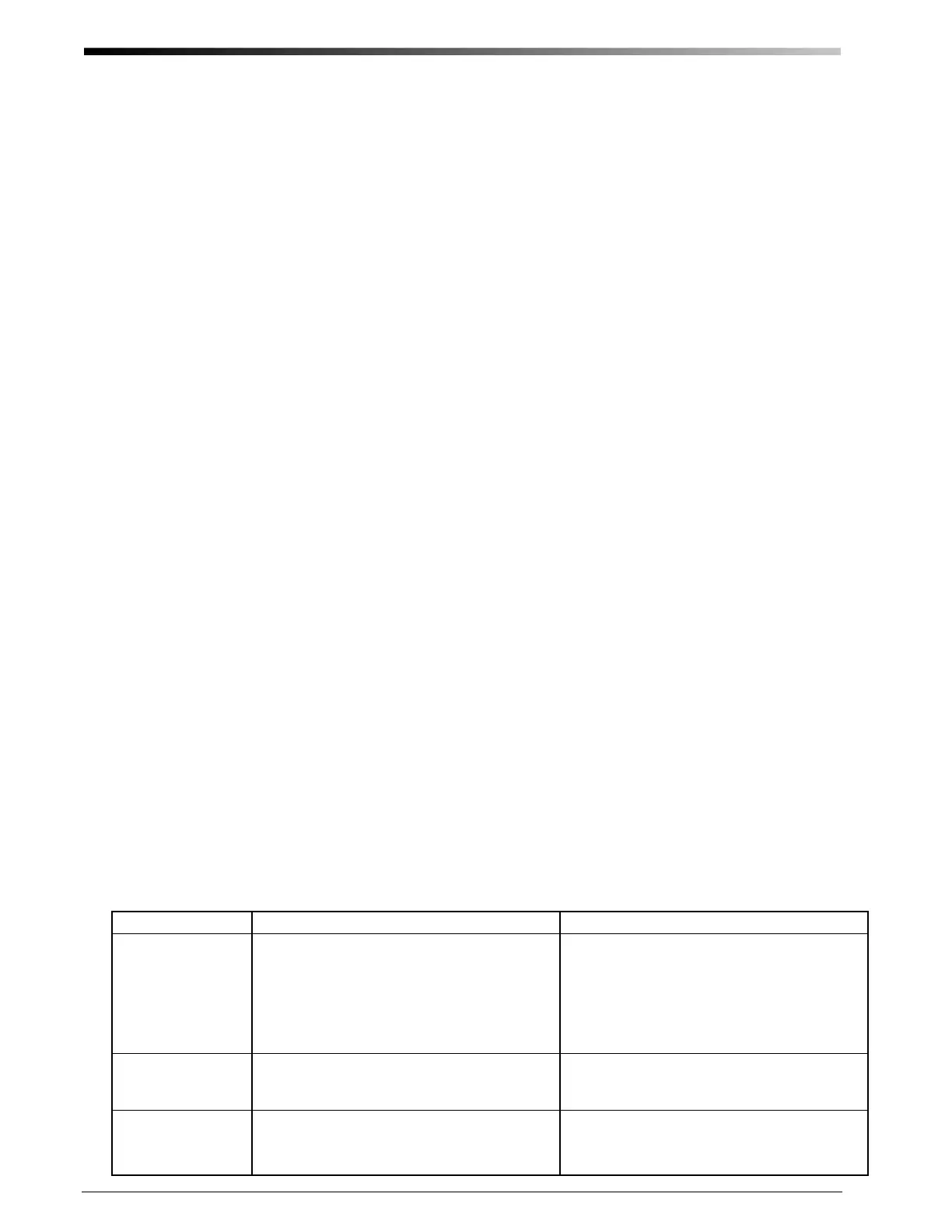

Table 7. Airflow Troubleshooting Chart

Problem Probable Cause Remedy

Low Static, Low Ampe-

rage

Restrictor set too low.

Blocked filters, restriction in return duct.

Low Voltage.

Blower Wheel not aligned properly.

Dirty blower wheel.

Open restrictor to table 4 setting.

Clear restriction.

Check with local utility.

Center wheel inside of inlet ring. Position on shaft for

1/8 inch (3 mm) clearance from inlet ring.

Clean wheel.

Low static, high ampe-

rage

Large number of outlets.

Restrictor setting to high.

Close restrictor to proper amperage, or

Add balancing orifices to outlets.

Close restrictor to obtain proper amperage.

High Static,

Low Amperage

Restrictive duct system. Add outlets, add splitter vane in tee, reduce the num-

ber of tees and elbows in plenum, increase plenum

size to 9” equivalent, or

Open restrictor to proper amperage.

Loading...

Loading...