25

Note:It is recommended that you refresh the Dark Current (refer to Page21) before check.

Stray Light Check

Specification: Less than 0.3%T at 340nm by ASTM E 387

A good indication as to whether the stray light level is within specification may be obtained as follows:

1. Set the wavelength to 340nm.

2. Select BASIC MODE With the sample compartment empty, close the lid and press the 0A/100%T

key to set the LCD display to 100.0%.

3. Prepare a solution containing 50gm/L of sodium nitrite (NaNO

2

) in distilled water and fill a square

cuvette with this solution.

4. Place the cuvette in the sample compartment. Close the lid. The display should read<0.3%T.

Note:It is recommended that you refresh the Dark Current (refer to Page21) before check.

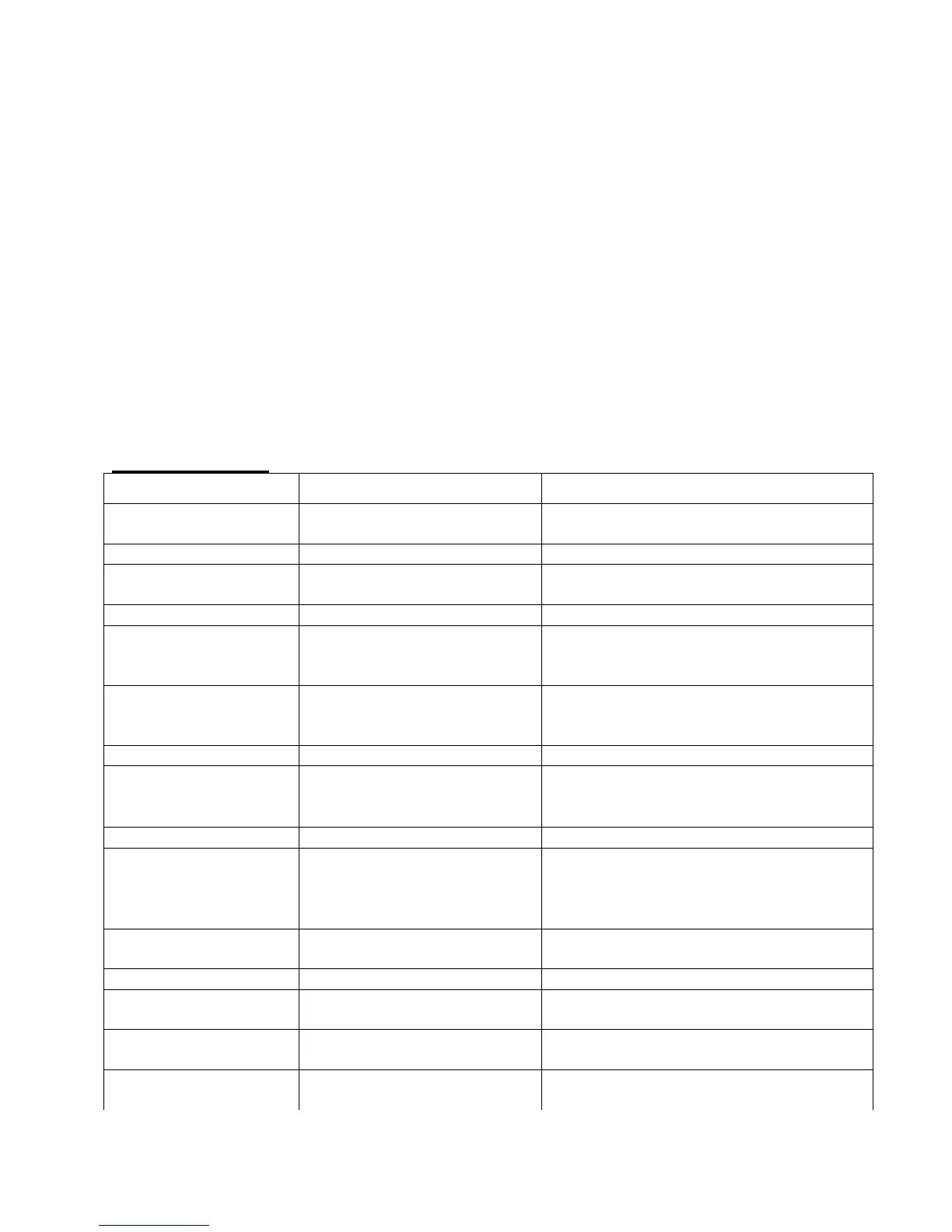

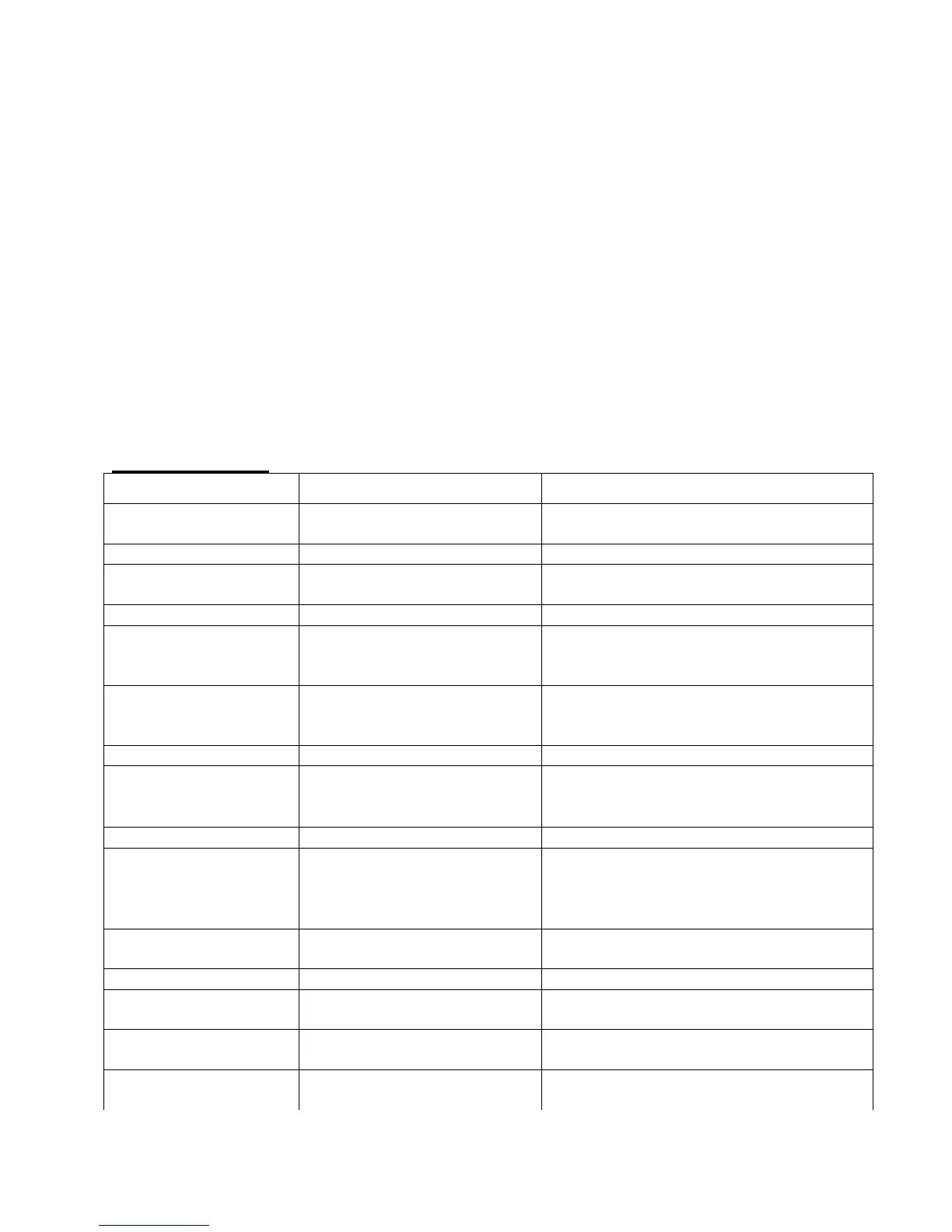

Trouble Shooting:

PROBLEM

Possible

Solution

Instrument Inoperative

Power cord not connected to

outlet

Plug instrument in.

Dead Power outlet Change to a different outlet

Internal fuse blown or defective

electronic component

Call an authorized service engineer.

Improper power setting Set to the main power

Instrument cannot set

100%T (0.000A)

Light beam blocked Check sample holder. See if holder is

properly positioned and nothing is blocking

light path.

Lamp is misaligned. Check to see if light is positioned properly on

entrance slit to monochromator. Call

Technical Service for details (800-588-9776).

Defective electronic component. Call an authorized service engineer.

Incorrect

Transmittance to

Absorbance correlation

Bubbles or particles in solution. Check sample preparation and analytical

procedure.

Defective electronic component. Call an authorized service engineer.

LCD Digital Display

does not change

regardless of sample

concentration

Concentration reading “frozen”. Sample Solution too Dark ,

dilute it and

Restart measurement procedure.

Wrong wavelength setting. Check sample procedure and wavelength

setting.

Insufficient sample volume. Fill cuvette with more sample.

Stray sample preparation vapors. Prepare the sample away from the

instrument. Use proper ventilation.

Bubbles or particles in solution. Check sample preparation and analytical

procedure.

Defective electronic component

or loose wiring.

Call an authorized service engineer.

Loading...

Loading...