44

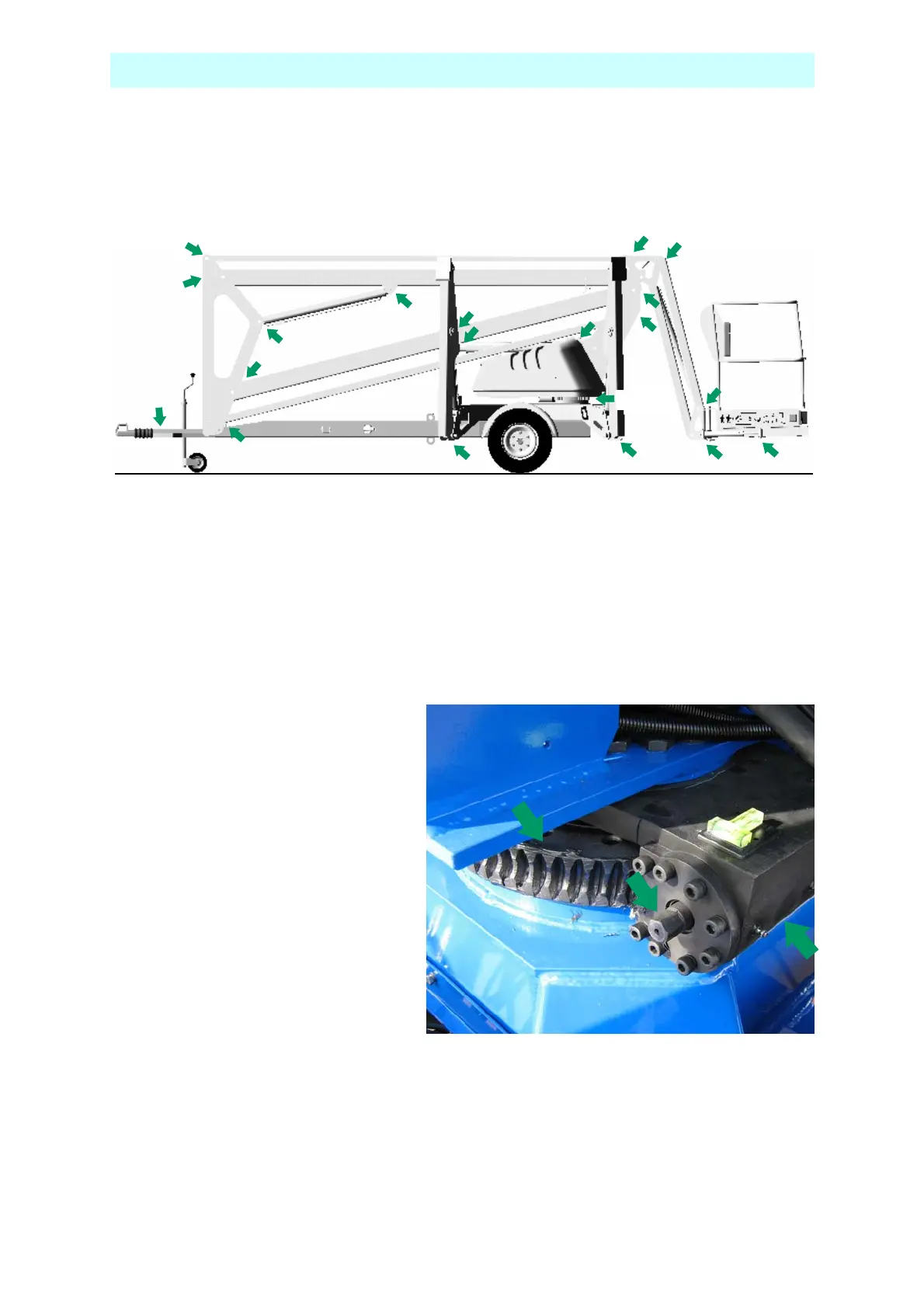

GENERAL GREASE POINTS

Regular greasing not only greatly improves the service life of the bushes, it also will remove

any moisture which may cause internal corrosion on the wall of the bosses making it difficult

to remove the pivot shafts for inspection.

LUBRICATION SPECIFICATIONS

We recommend only using premium quality grease. Experience has shown that a Lithium

based grease offers very good performance. For the slew ring the RENOLIT ARMNA

G4789 from Fuchs offers extremely good lubrication and anti corrosion properties.

Especially at very low temperatures (-30DegC)

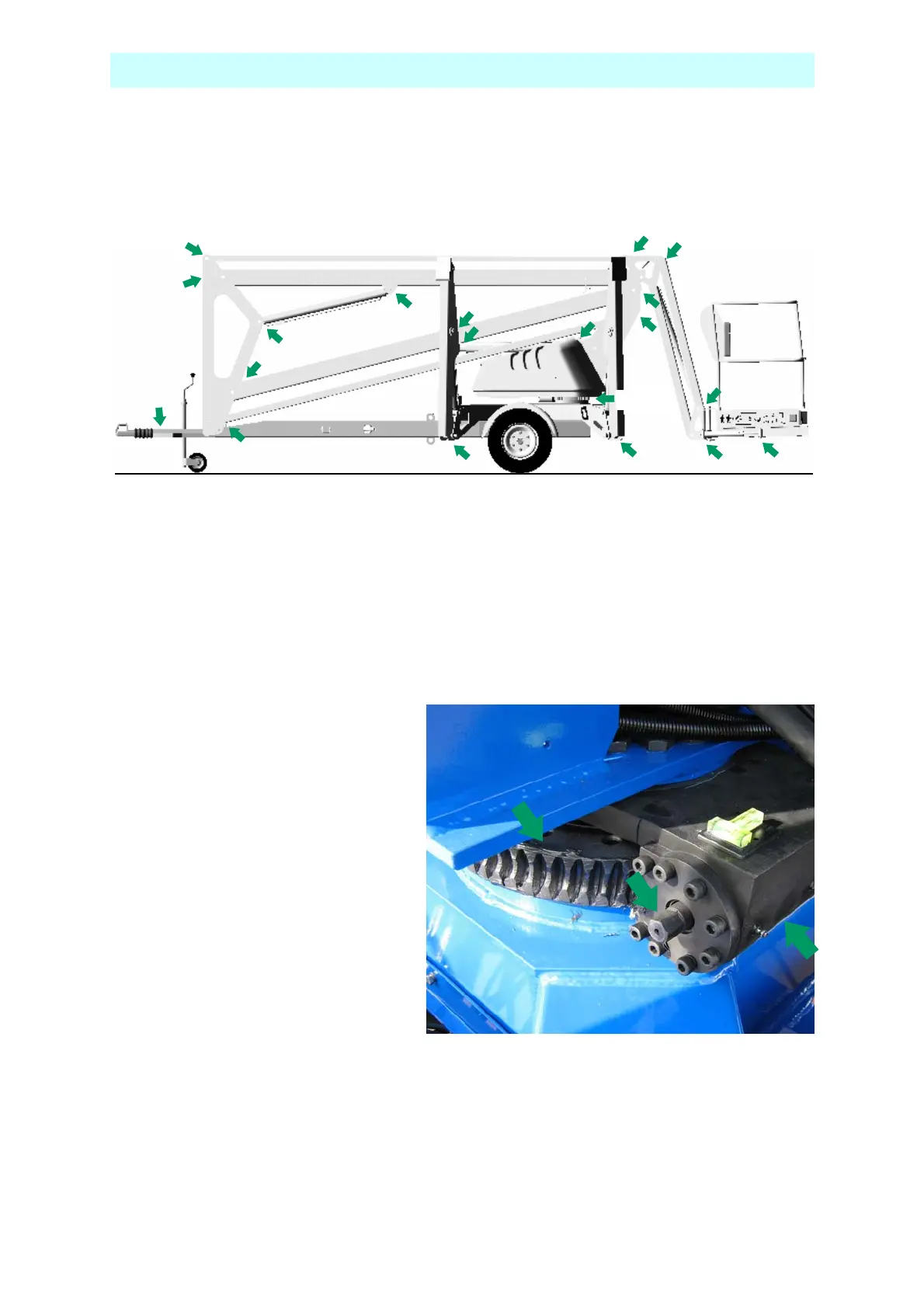

Slew Drive

SLEW DRIVE

To grease the slew ring you must set

the machine up and slew around so

you can gain access to the reas-

sessed grease nipple fitted to the top

face of the slew ring.

When greasing the worm housing

take care not to push out the oil seal

on the end face. If you do, remove

excess grease from the end and drive

the seal back in.. See Slew Drive

Gear section for more details.

MAINTENANCE PROCEDURE

Loading...

Loading...