Page 3-10

Maintenance 3.7 - Hydraulic Oil Tank and Filter

TL38 Service & Parts

3.7 HYDRAULIC OIL TANK AND FILTER

FLUID LEVEL

With the platform fully lowered, open the equipment module and remove the reservoir breather/

cap. Oil should be at the full mark.

OIL AND FILTER REPLACEMENT

1. Operate the work platform for 10-15 minutes to bring the hydraulic oil up to normal operat-

ing temperature.

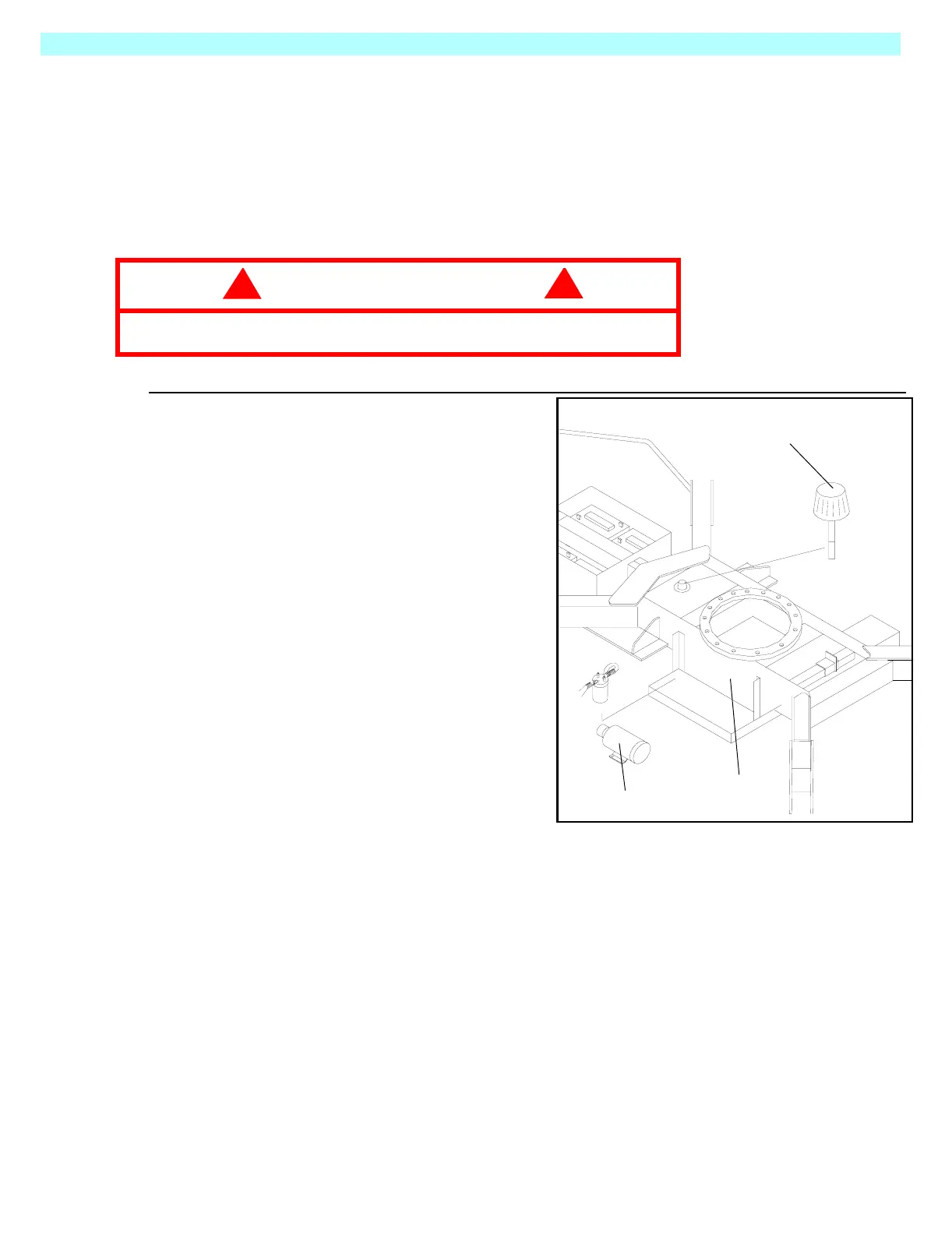

Figure 3-3: Oil Filter

2. Provide a suitable container to catch

the drained oil. Hydraulic tank has a

19 L (5 gallon) capacity.

3. Open module door.

4. Locate and remove the drain plug and

allow all the oil to drain. Dispose of

hydraulic fluid properly (contact your

local oil recycler).

5. Reinstall the drain plug.

6. Unscrew the filter from the filter

assembly.

7. Apply a thin film of clean hydraulic oil

(ISO #46) to the gasket of the

replacement filter.

8. Screw the replacement filter onto the

filter head until the gasket makes

contact, then turn the filter 3/4 of a

turn further.

9. Fill the hydraulic reservoir with ISO

#46 hydraulic oil until the oil is up to

the full mark on the dipstick.

RESERVOIR BREATHER/CAP

Clean the breather/cap at the same time that the oil filter is replaced. Use cleaning solvent and

blow dry with clean, dry compressed air.

CAUTION

!

!

The hydraulic oil may be of sufficient temperature to cause burns. Wear

safety gloves and safety glasses when handling hot oil.

Filter

Chassis

Pump & Motor

Loading...

Loading...