Page 4-3

Troubleshooting 4.3 - Troubleshooting Guide

TL38 Service & Parts

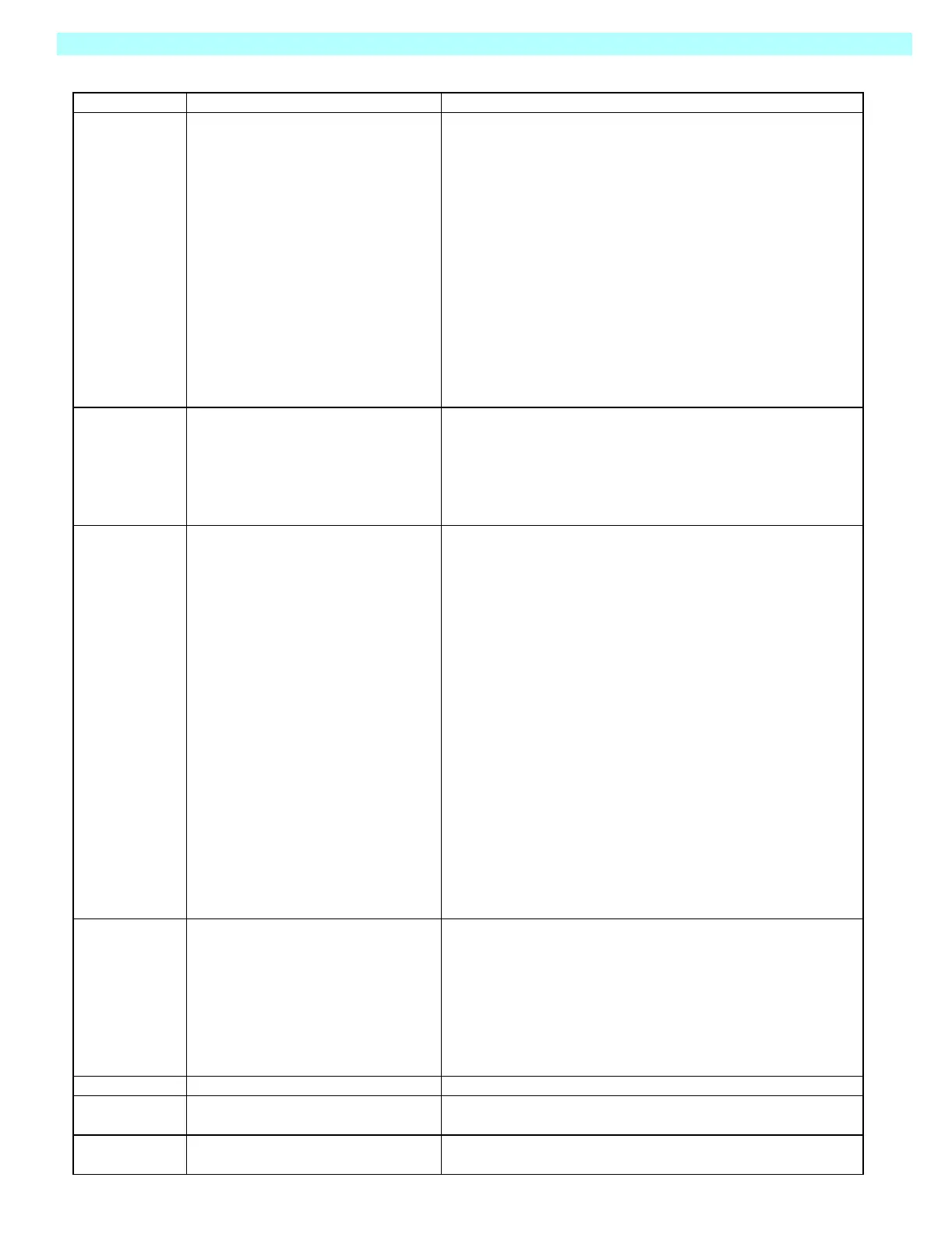

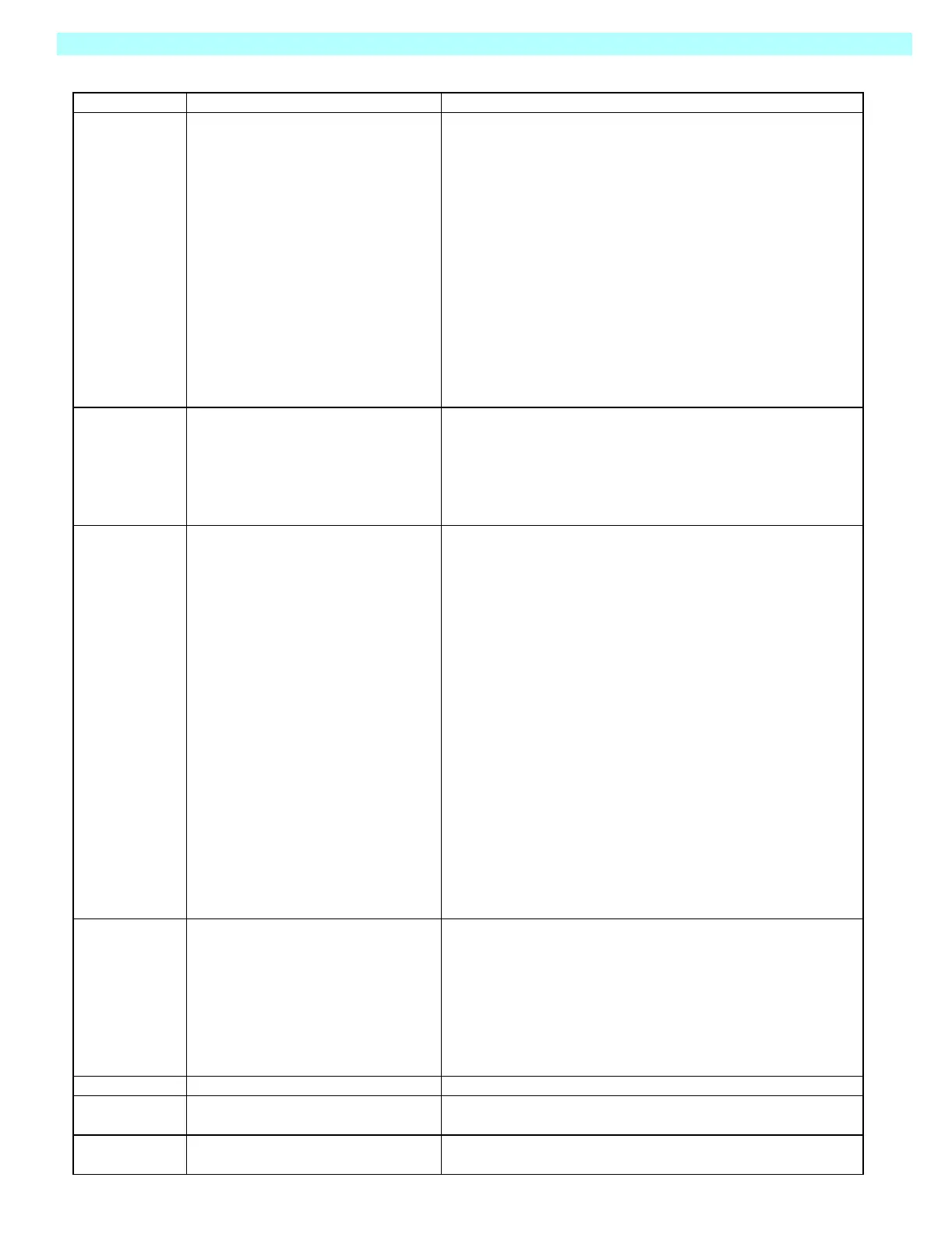

TROUBLE PROBABLE CAUSE REMEDY

1. Blown electric motor fuse Check 160 amp electric motor fuse. R eplace if blown.

2. Faulty battery Check the voltage output of the battery charger. If less than 24 VDC,

charger.

3. F a ulty ba tte ry( ies ). Afte r c omplete ly cha rging ba tte rie s , te s t ea ch ba ttery. R epla c e a s

4. Loose or broken Check continuity of all battery and motor leads. Replace if necessary.

ba ttery lea d.

5. E mergency Stop With emergency stop switch in the ON position, check continuity

switch(es ) failed open.

6. B lown control fuse C heck 7A circuit control fuse. R eplace if blown.

1. Oil level in hydraulic C heck hydraulic fluid level, top off as required.

reservoir is low.

2. F aulty hydraulic C heck press ure and delivery of the hydraulic pump. R eplace if

pump.

1. E mergency Close emergency

Lowering valve down valve.

open.

2. P latform Observe maximum load rating. (see Operation section of this manual)

overloaded.

3. F aulty controller at C heck functionality of controller. R eplace if faulty.

upper controls.

4. B lown control fuse C heck 7A circuit contrrol fuse. R eplace if blown.

5. B attery level low. C heck B attery V oltage. C harge if necessary.

C heck for fault code 68

6. Outrigger limit E ns ure all four outriggers are deployed and the

switches not activated limit switch contacts are closed.

Replace switch.

1. E mergency E nsure that emergency lowering valve is completely clos ed. R eplace

lowering valve

open.

2. Leaking piston Check for leakage at cylinder return line, replace seals if necessary.

seals in lift

cylinders

O utrigger B oom re s t limit s witch is not activa ted or E ns ure booms a re s towe d. C heck tha t N orma lly O pe n conta cts of limit

C heck that Normally C los ed contacts of limit s witch are closed when

Adjust switch lever arm or R eplace switch.

J ib cylinder will not

re tra c t or exte nd.

All functions

inoperable,

electric motor

does not s ta rt.

All functions

inoperable.

E lectric motor

starts when

control is

actuated.

P latform will not

elevate or

elevates slowly.

C lose S hutoff ball valve.

B ooms drift down

after being

elevated

Machine will not

slew when booms

F aulty s lew cut-out limit switch

S hutoff ball valve is open.

4.3 TROUBLESHOOTING GUIDE

Loading...

Loading...