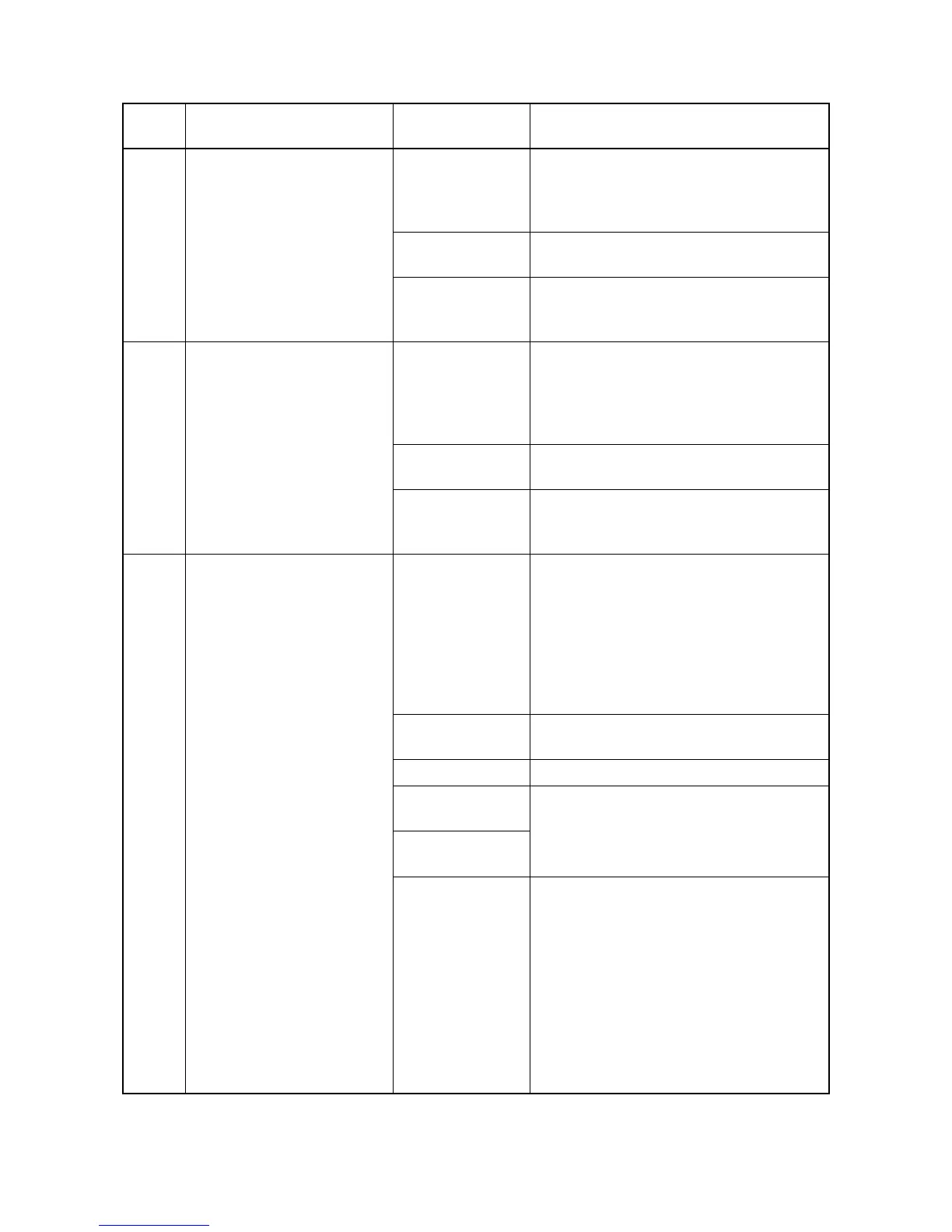

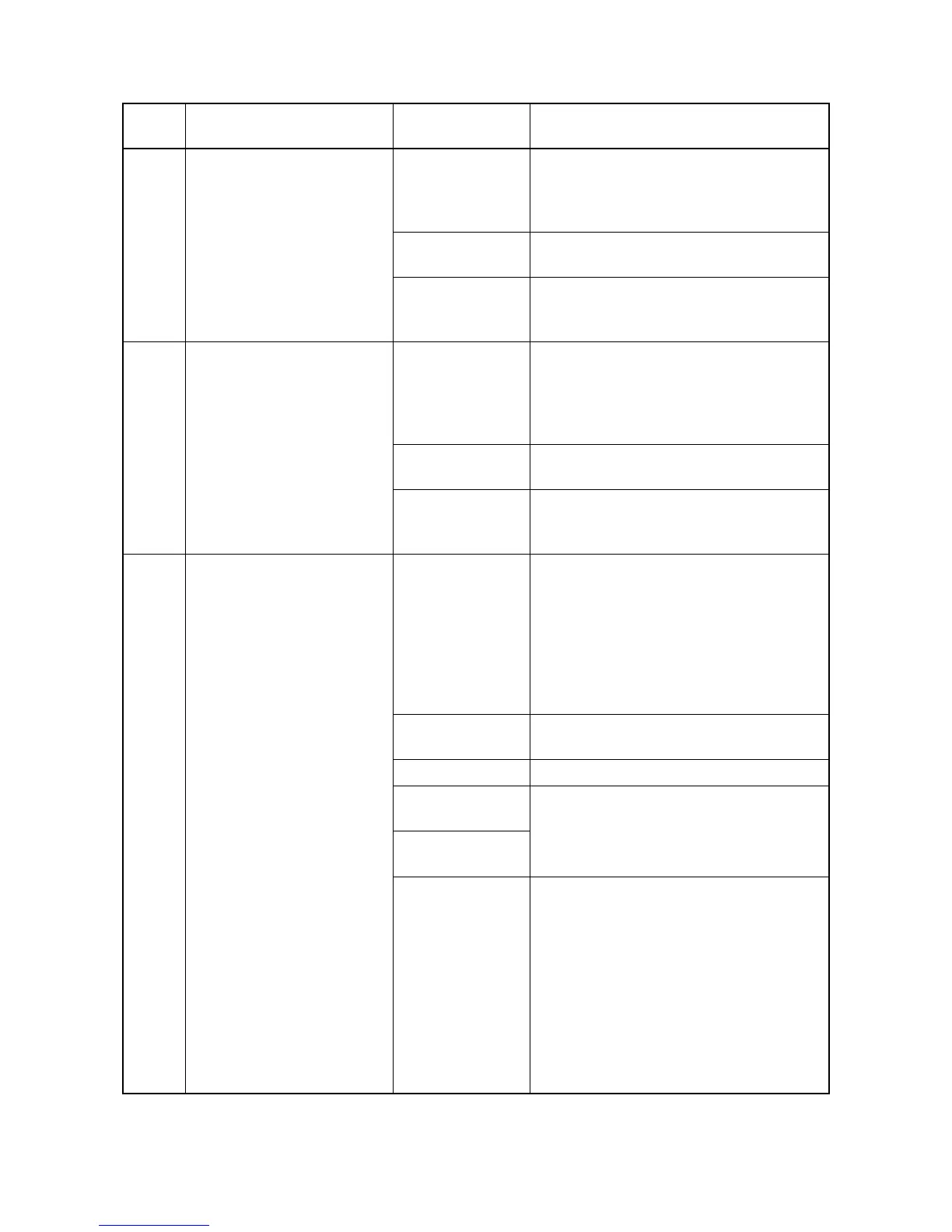

2LV/2L1/2L2/2MS/2MT

1-4-17

4200 BD steady-state error

When the value of Register

BDSET is 1 after setting Reg-

ister BDSET as one and pass-

ing by BD1 cycle.

Defective connec-

tor cable or poor

contact in the con-

nector.

Reinsert the connector. Also check for conti-

nuity within the connector cable. If none,

replace the cable.

PD PWB and engine PWB (YC16)

Defective PD

PWB.

Replace the laser scanner unit (see page 1-

5-18).

Defective engine

PWB.

Replace the engine PWB and check for cor-

rect operation (see page 1-5-22).

5100 Chager current error

When the current value mea-

sured at the time of potential

adjustment is less than 20 μA.

When the current values in

the chager voltage 500V con-

stitute not less than 85% of

target current values.

Defective connec-

tor cable or poor

contact in the con-

nector.

Reinsert the connector. Also check for conti-

nuity within the connector cable. If none,

replace the cable.

Chager unit and high voltage PWB

High voltage PWB and engine PWB (YC16)

Defective high

voltage PWB.

Replace the high voltage PWB and check

for correct operation (see page 1-5-26).

Defective engine

PWB.

Replace the engine PWB and check for cor-

rect operation (see page 1-5-22).

6000 Broken fuser heater wire

(60/50/45 ppm model)

The detection temperature of

fuser thermistor 2 is 100 °C/

212°F or less after the fuser

heater lamp has been turned

on continuously for 30 s.

(40 ppm model)

The detection temperature of

fuser thermistor 1 is 100 °C/

212°F or less after the fuser

heater lamp has been turned

on continuously for 30 s.

Defective connec-

tor cable or poor

contact in the con-

nector.

Reinsert the connector. Also check for conti-

nuity within the connector cable. If none,

replace the cable.

Fuser heater and power source PWB (YC2)

Fuser thermistor and Fuser thermistor con-

nect PWB

Fuser thermistor connect PWB and engine

PWB (YC21)

Deformed connec-

tor pin.

See page 1-4-19.

Defective triac. See page 1-4-19.

Fuser thermostat

triggered.

Reinsert the fuser unit (see page 1-5-19).

Broken fuser

heater wire.

Defective engine

PWB.

Replace the engine PWB and check for cor-

rect operation (see page 1-5-22).

Code Contents Causes

Check procedures/

corrective measures

Loading...

Loading...