page 20 of 27

Documents are only to be used and distributed completely and unchanged. It is strictly the users´ responsibility to check carefully

the validity of this document with respect to his product. 25/11/2013 // 999281

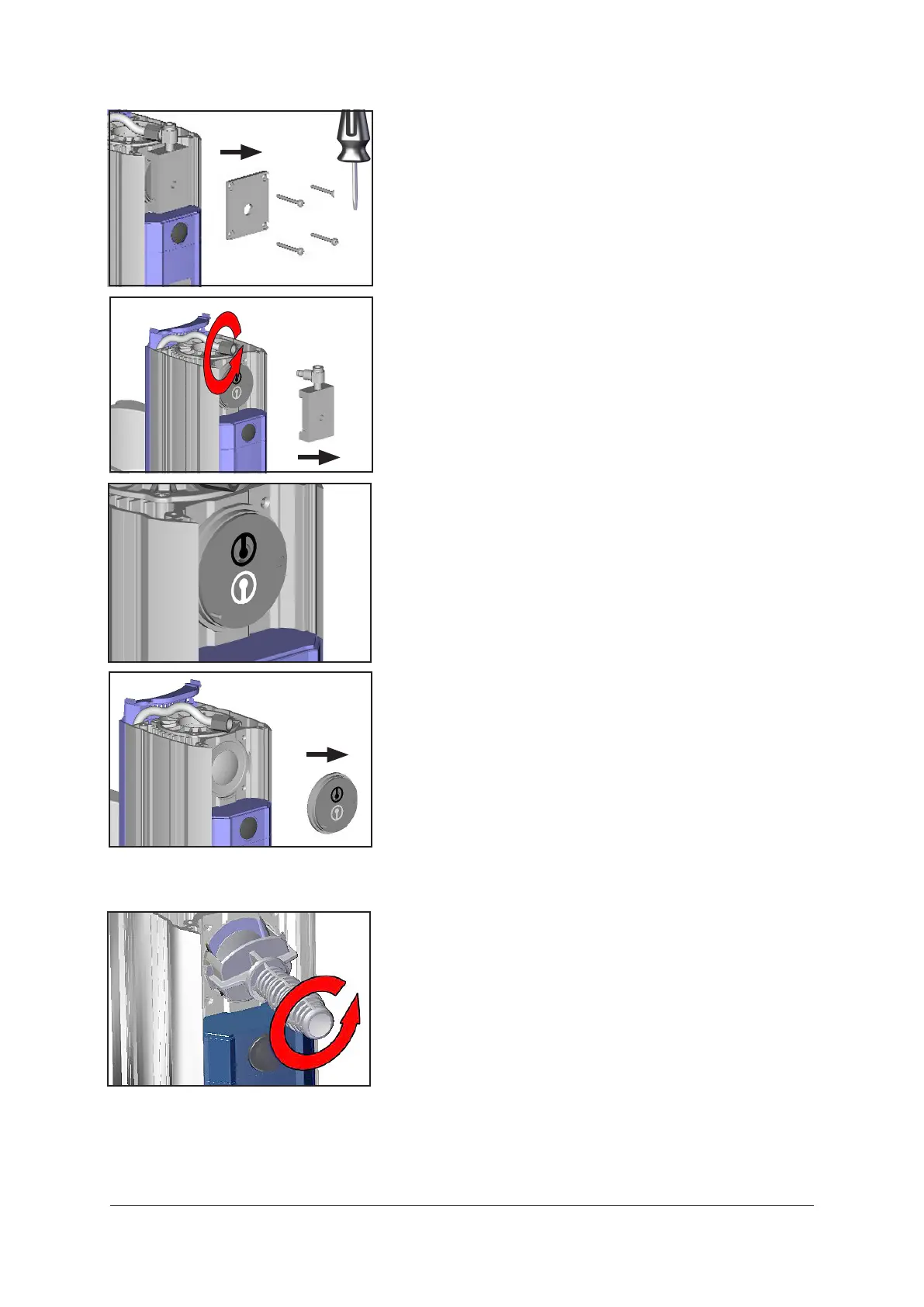

➨ Lift diaphragm carefully sidewise.

+ Never use a pointed or sharp-edged tool to lift the dia-

phragm.

➨ Usethediaphragmkeytogripthediaphragmsupportdisc

below the diaphragm.

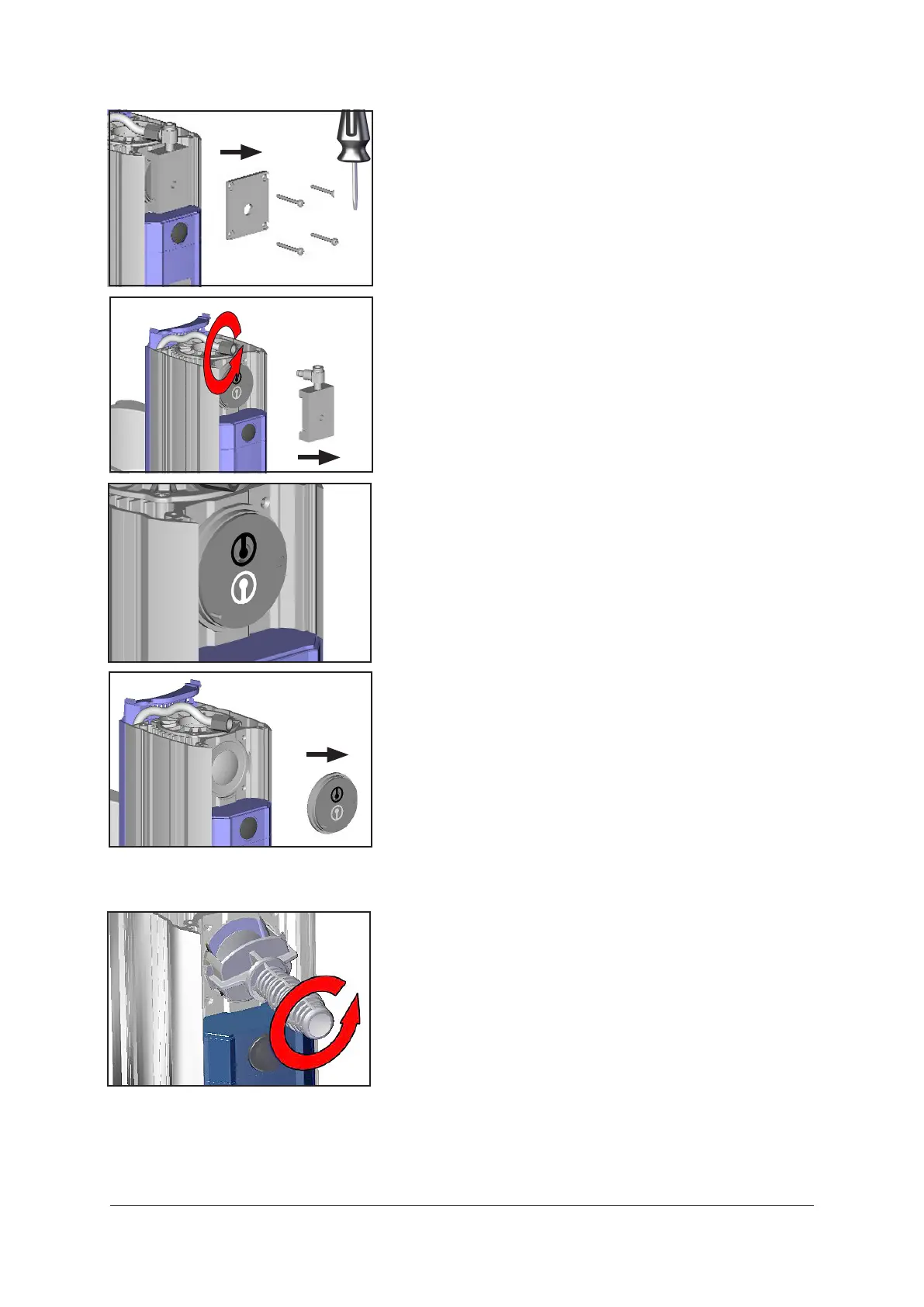

➨ Press down the diaphragm clamping disc to bring the

diaphragmtoitslowestoscillatingposition.Unscrewdia-

phragm support disc with diaphragm and diaphragm clam-

ping disc.

+ Ifthediaphragmisdifculttoseparatefromthediaphragm

support disc, immerse assembly in naphtha or petroleum

ether.Donotinhalevapors!

+ Check for washers between the diaphragm support disc

andtheconnectingrod.Makesurethattheoriginalnum-

ber is reassembled.

➨ Note position of valves.

➨ Unscrewfourscrewsatthepumphead,payingattention

to washers.

Remove housing cover.

➨ Unscrewunionnutandremovehosefromelbowtting.

➨ Removehousingcoverinsertwithelbowtting.

➨ Remove head cover and valves.

+ Checkdiaphragmfordamage.

+ Attention: In case of a defect diaphragm the interior

of the pump housing has to be decontaminated, e. g.,

using a spray disinfection.

+ The appropriate decontamination method has to be

ensured by the user.

+ Never remove parts by using a pointed or sharp-edged

tool(e.g., screw driver),we recommend touse a rubber

malletorcompressedair(tobeblowncarefullyintoport).

Loading...

Loading...