16 Installation and maintenance manual ecoTEC

3.11 Pump specifications

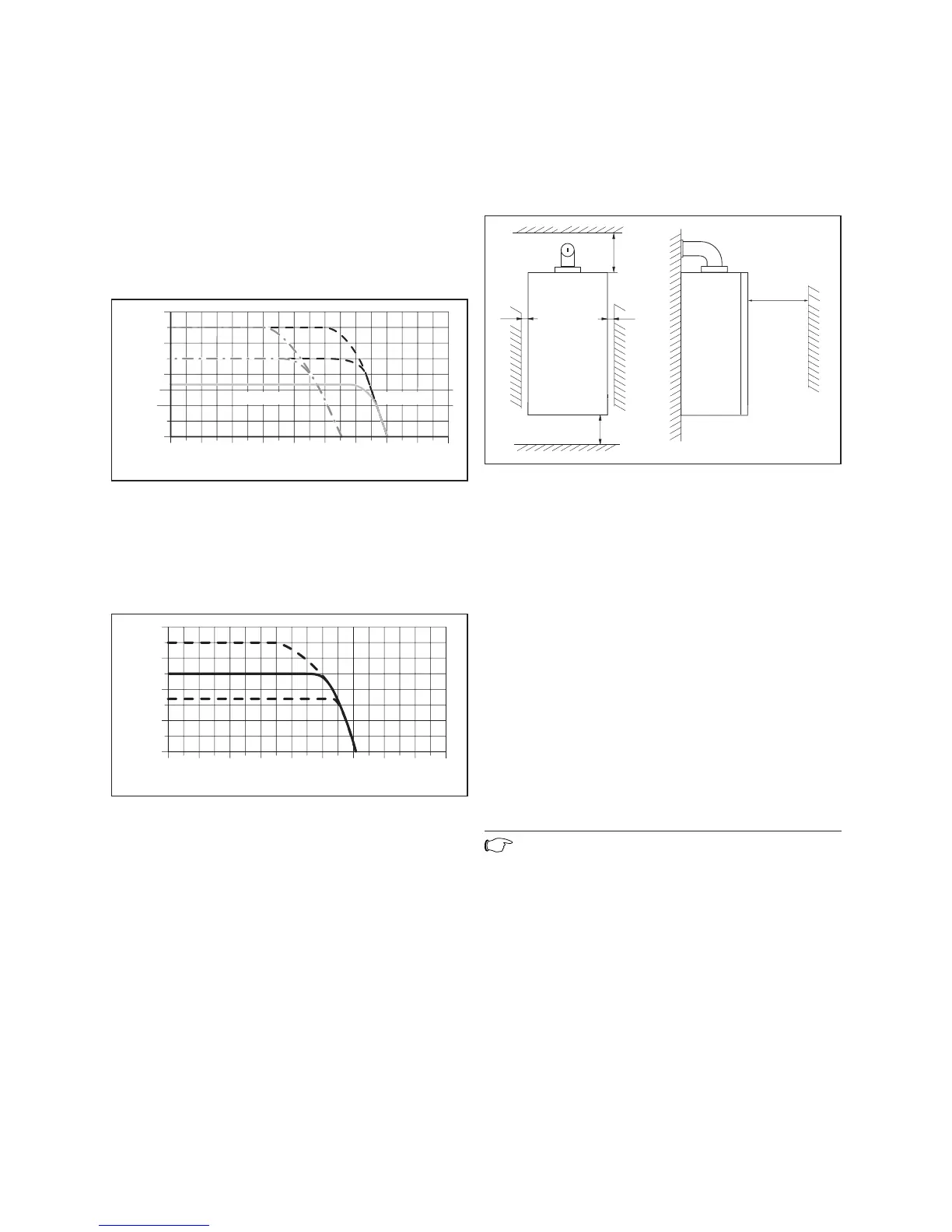

3.11.1 Circulating pump

only ecoTEC plus:

The circulating pump is included in the boiler. The resid-

ual pump discharge height depending on the overflow

valve is shown in Fig. 3.10.

The operating mode of the 2-step pump can be adjusted

below the diagnosis point d.12, see Section 8.1.2.

400

300

200

100

0

0 200 400 600 800 1000 1200 1600

Lift

[

mbar

]

Volumeflow

[

l/h

]

1800

1400

2. Step1. Step

Fig. 3.10 Pump specifications ecoTEC plus

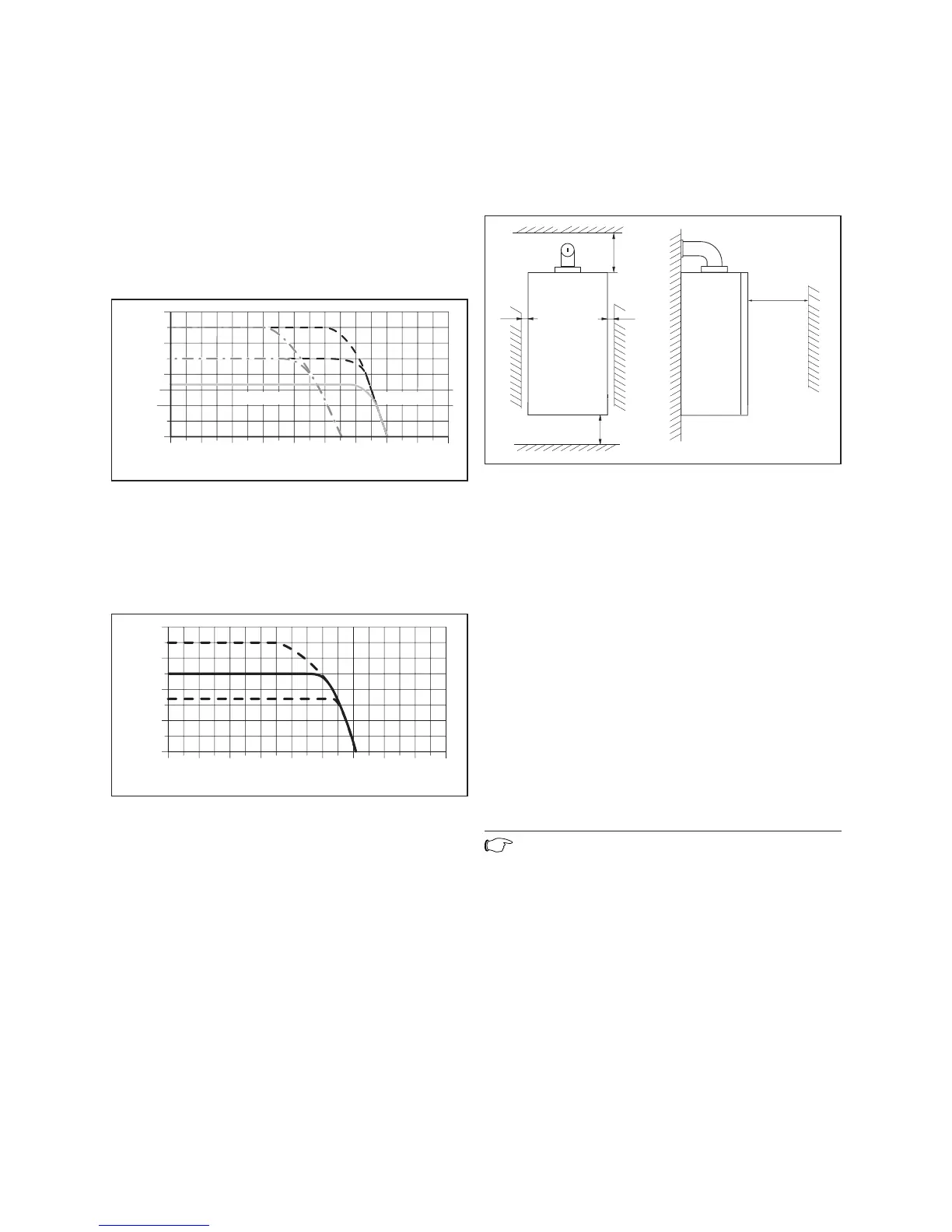

only ecoTEC pro:

The circulating pump is included in the boiler. The eco-

TEC pro appliances are fitted with a single-stage pump.

The residual pump discharge height depending on the

overflow valve is shown in Fig. 3.11.

400

300

200

100

0

0 200 400 600 800 1000 1200 1600

Lift

[

mbar

]

Volumeflow

[

l/h

]

1800

1400

Fig. 3.11 Pump specifications ecoTEC pro

3.11.2 System bypass

An automatic system bypass is provided in the boiler.

The boiler is suitable for use in systems with thermostat-

ic radiator valves and no additional bypass is required.

The overflow valve is adjustable, see Section 5.8.

3.11.3 Venting

The boiler is fitted with an automatic air vent. Additional

provision should be made to enable the heating system

to be vented during filling and commissioning either by

automatic air vents or manually.

3.12 Condensate trap

The boiler is fitted with a siphon condensate discharge

(ecoTEC plus) or a condensate trap (ecoTEC pro) incor-

porating a water trap of 140 mm.

4 Boiler installation sequence

4.1 Required minimum distances/assembly clear-

ances

min

min 5

min 5

min 500**

min 180

167/246*

Fig. 4.1 Distances during installation (dimensions in mm)

Both for the installation/assembly of the appliance and

also for carrying out maintenance tasks later, you need

the minimum distances and minimum assembly clear-

ances given below:

– side distance: 5 mm on each side

– lower side 180 mm

– upper side*: 167 mm for flue system

Ø 60/100

246 mm for flue system

Ø 80/125 mm

– front side**: 500 mm

This distance is needed for easier

access during maintenance tasks.

It is not necessary to keep a clearance between the

appliance and combustible substances or components,

as at the rated heating power of the appliance, the tem-

perature here is always lower than the permitted tem-

perature of 85 °C.

Note

If the boiler is to be fitted in a timber framed

building, it should be fitted in accordance with

British Gas publication DM2 ‘Guide for gas

installations in timber framed housing’.

3 General requirements

4 Boiler installation sequence

Loading...

Loading...