Appendix

0020257319_02 Hydraulic station Installation and maintenance instructions 47

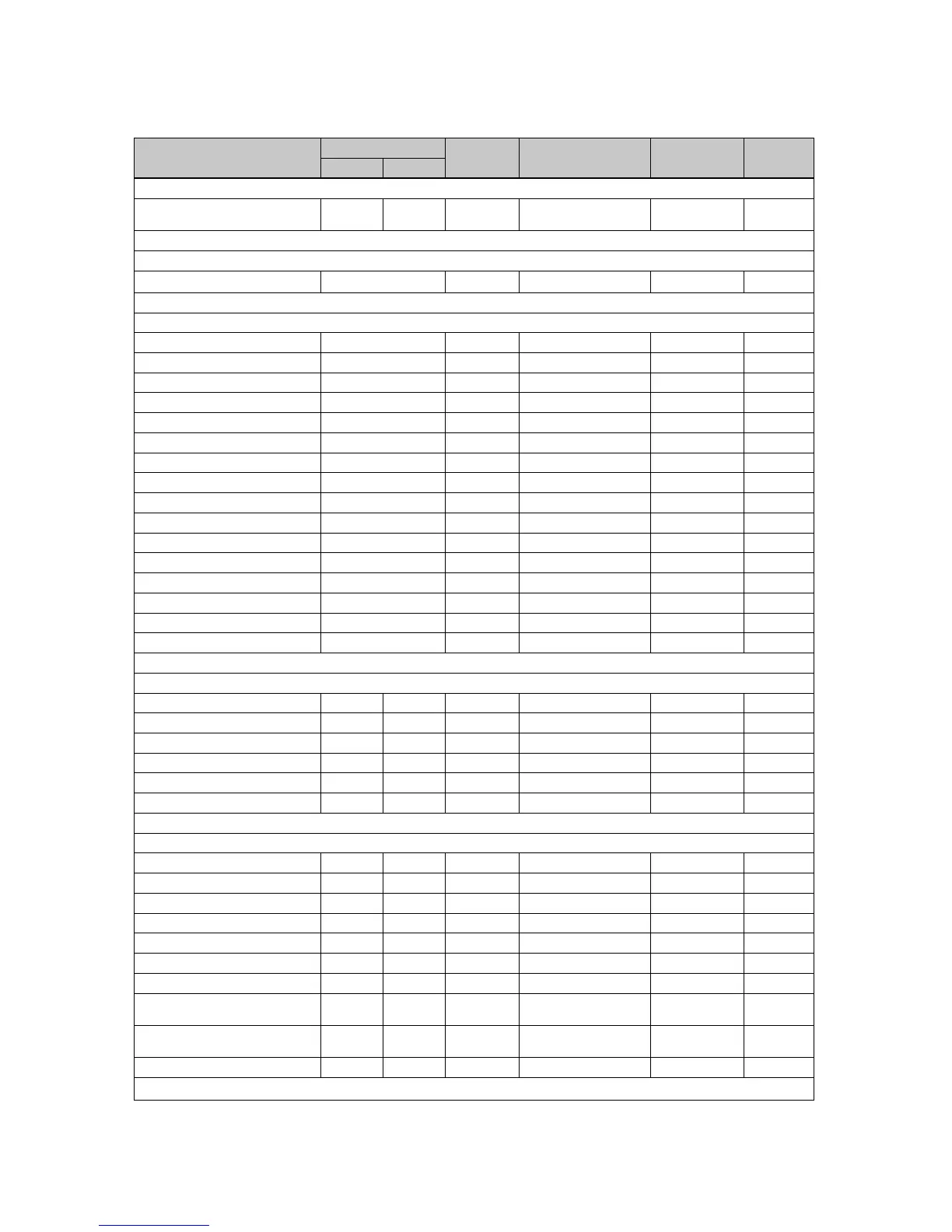

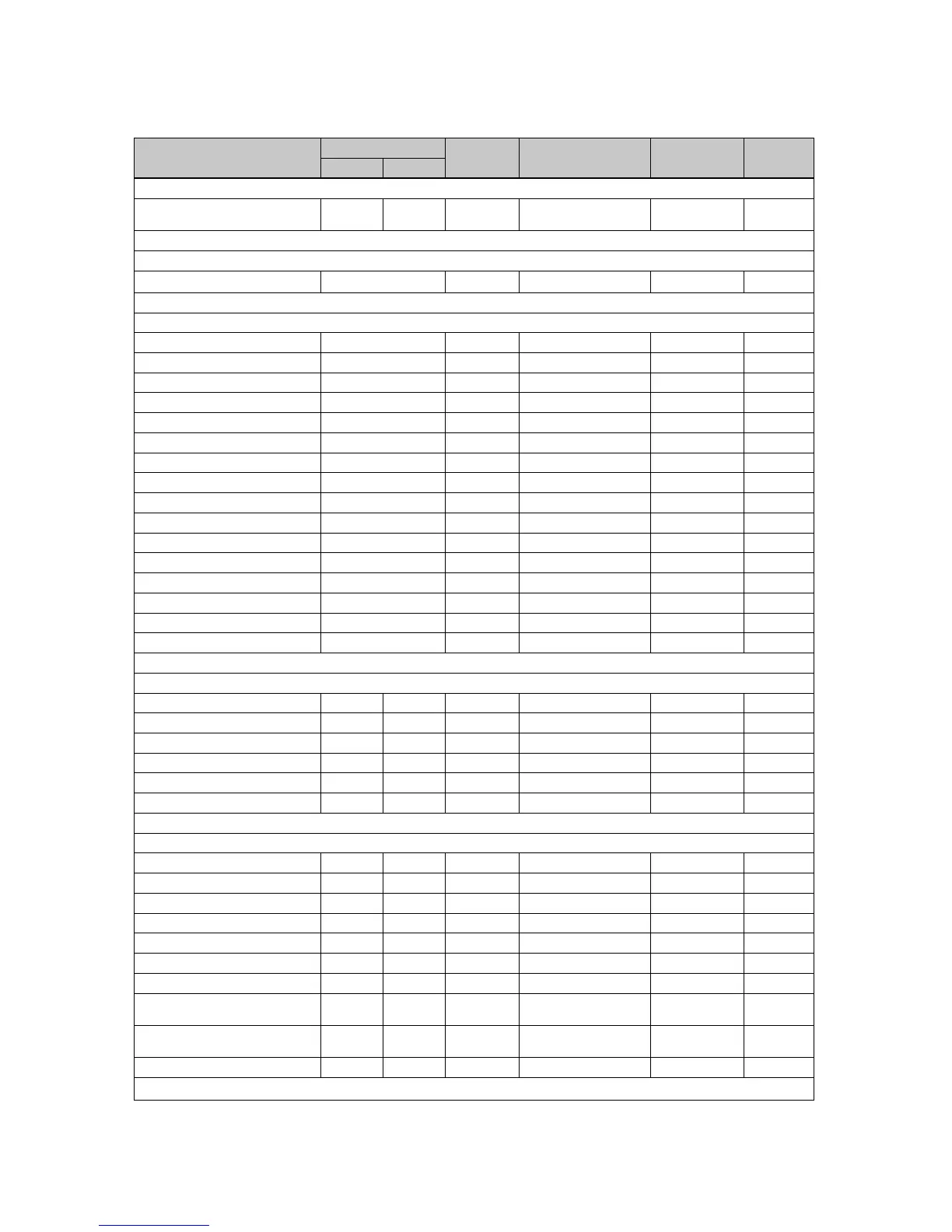

E Installer level overview

Setting level Values Unit Increment, select, ex-

planation

Factory setting Setting

Min. Max.

Installer level →

Enter code 00 99 1 (competent person

code 17)

00

Installer level → Fault list →

F.XX – F.XX

1)

Current value

Installer level → Test menu → Statistics →

Compressor hours Current value h

Compressor starts Current value

Build. pump hours Current value h

Build. pump starts Current value

4-port valve hours Current value h

4-port valve sw. ops Current value

Fan 1: Hours Current value h

Fan 1: Starts Current value

Fan 2: Hours Current value h

Fan 2 starts Current value

EEV steps Current value

DHW PDV switch. ops Current value

Im. heater power cons. Current value kWh

Im. heater op. hours Current value h

Im. heater switch. ops Current value

No. switch. ops Current value

Installer level → Test menu → Check programmes →

P.04 Heating mode Select

P.06 Purge building circuit Select

P.11 Cooling mode Select

P.12 De-icing Select

P.27 Immersion heater Select

P.29 High pressure Select

Installer level → Test menu → Sensor/actuator test →

T.0.17 Fan 1 0 100 % 5 0

T.0.18 Fan 2 0 100 % 5 0

T.0.19 Condensate tray heater Off On On, Off

T.0.20 4-port valve Off On On, Off

T.0.21 Position: EEV 0 100 % 5 0

T.0.23 Heating coil compressor Off On On, Off

T.0.48 Air inlet temperature -40 90 ℃ 0.1

T.0.55 Compressor outlet tem-

perature

-40 135 ℃ 0.1

T.0.56 Compressor inlet temper-

ature

-40 90 ℃ 0.1

T.0.57 EEV outlet temperature -40 90 ℃

1)

See the overview of fault codes: Fault lists are only available, and can only be deleted, if faults have occurred.

Loading...

Loading...