Rainger Linear 47

OPERATION

Closed Delivery

Cart Path

The cart path must be maintained in a smooth, hard

condition to allow the poly hose to slide freely over

the surface.

Poly Hose

The standard poly hose wall thickness varies de-

pending on which inlet the hose is used on and the

size of hose.

Inlet Size Wall Thickness

Side Inlet 4.75 in SDR 17

6 in SDR 11

Center Inlet 8 in SDR 17

A heavier wall SDR 11 – 6 in poly hose is used with

the side inlet because of the tighter bending radius of

the hose and the stresses of auto reversing.

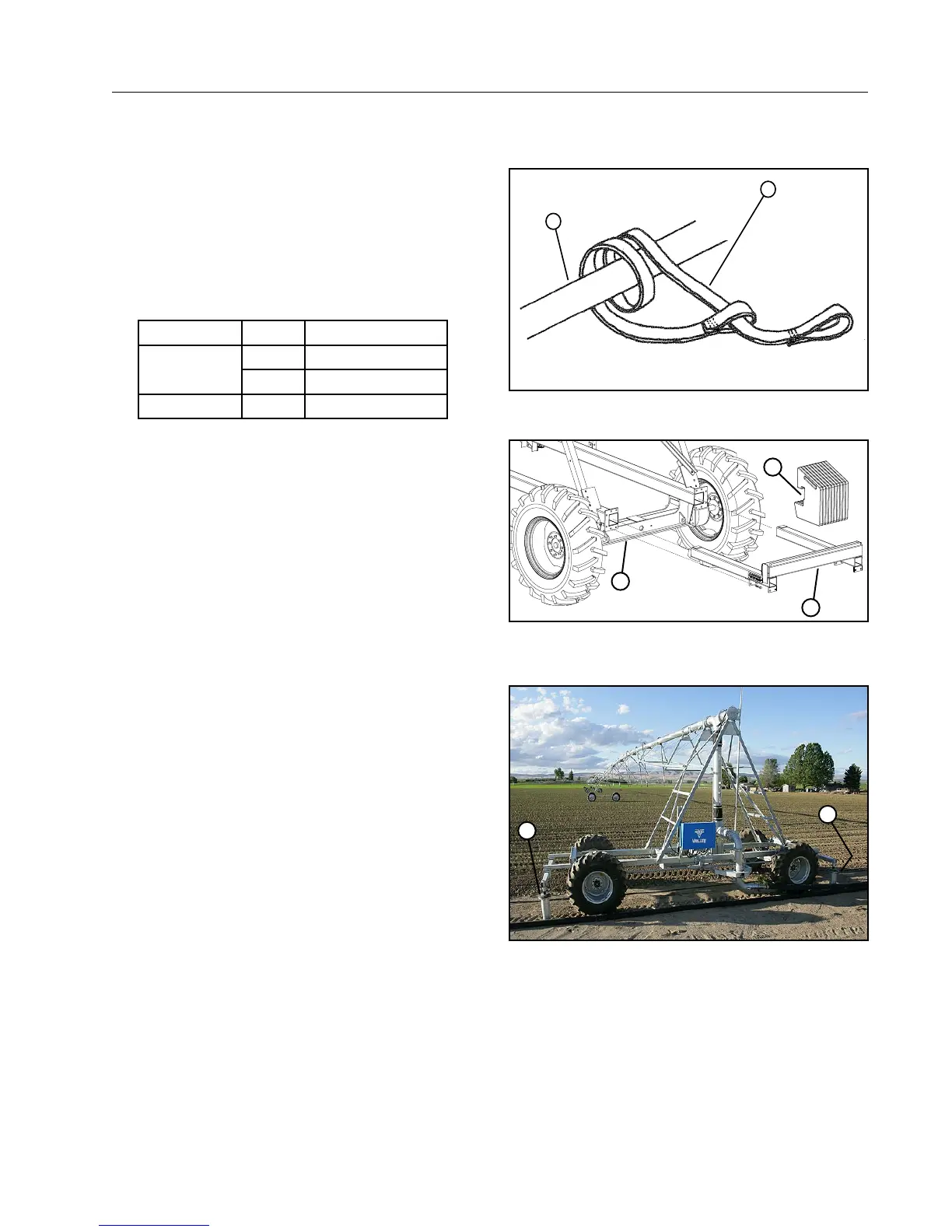

Moving Poly Hose

Use a 5 ft (1.5 m) nylon sling as shown when moving

poly hose. See Figure 47-1.

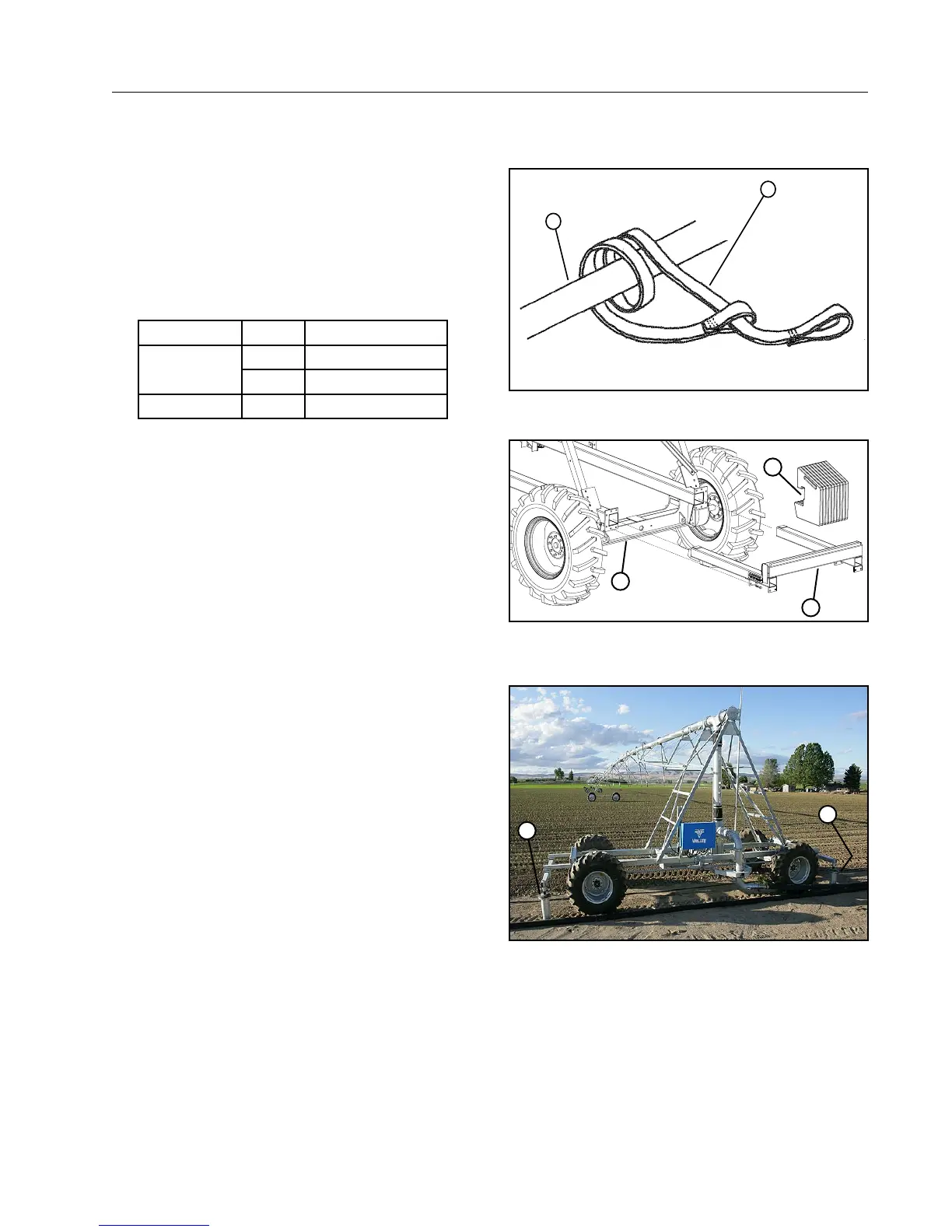

Cart Weight

Weight may be added to the cart as required for

increasing the hose pulling capability. The cart tires

may be filled with a weight additive and other weights

added to the cart frame as needed. See Figure 47-2.

Hose Bumpers

The installation of hose bumpers on the cart can re-

duce the hose handling labor, but may require heavier

wall SDR 13.5 or SDR 11 poly hose due to the tighter

bending radius of the hose. See Figure 47-3.

Pump

To boost water pressure after the hose, the Rainger

Linear hose drag cart can be equipped with an en-

gine driven pump.

2

1

Figure 47-1 1. Poly Hose

2. Sling

2

1

3

Figure 47-2 1. Linear cart

2. Tractor weights (Obtain Locally)

3. Weight rack assembly

1

1

Figure 47-3 1. Hose Bumper

Loading...

Loading...