86 Rainger Linear

MAINTENANCE

Machine Alignment

Floating Alignment Adjustment

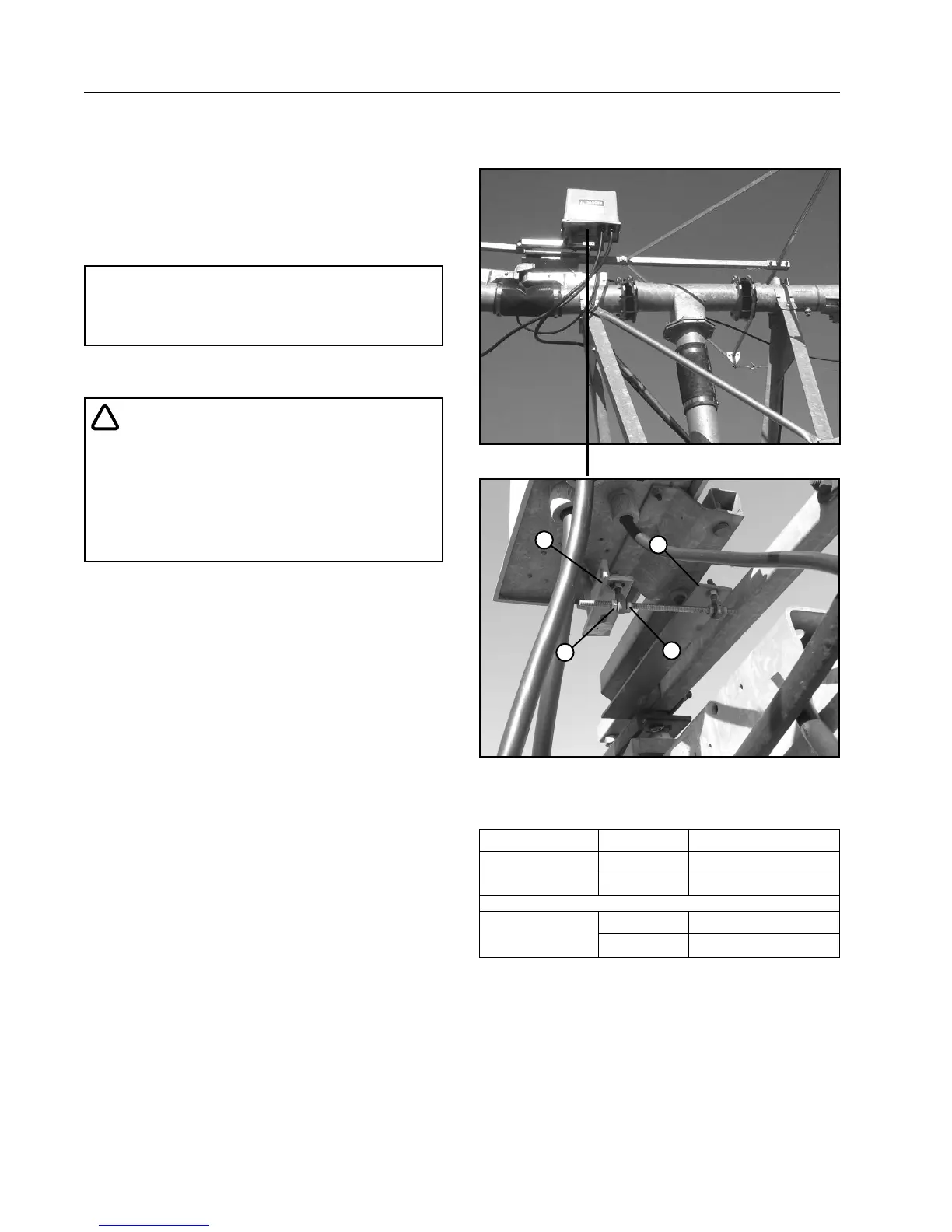

When a machine is equipped with floating alignment

the tower box is located on the yoke and tower box

support with a mechanical linkage between the tower

box switch pivot arm and the yoke control rod. See

Figures 86-1 and 86-2.

NOTE

• All adjustments shown are made from the

tower box side of drive unit.

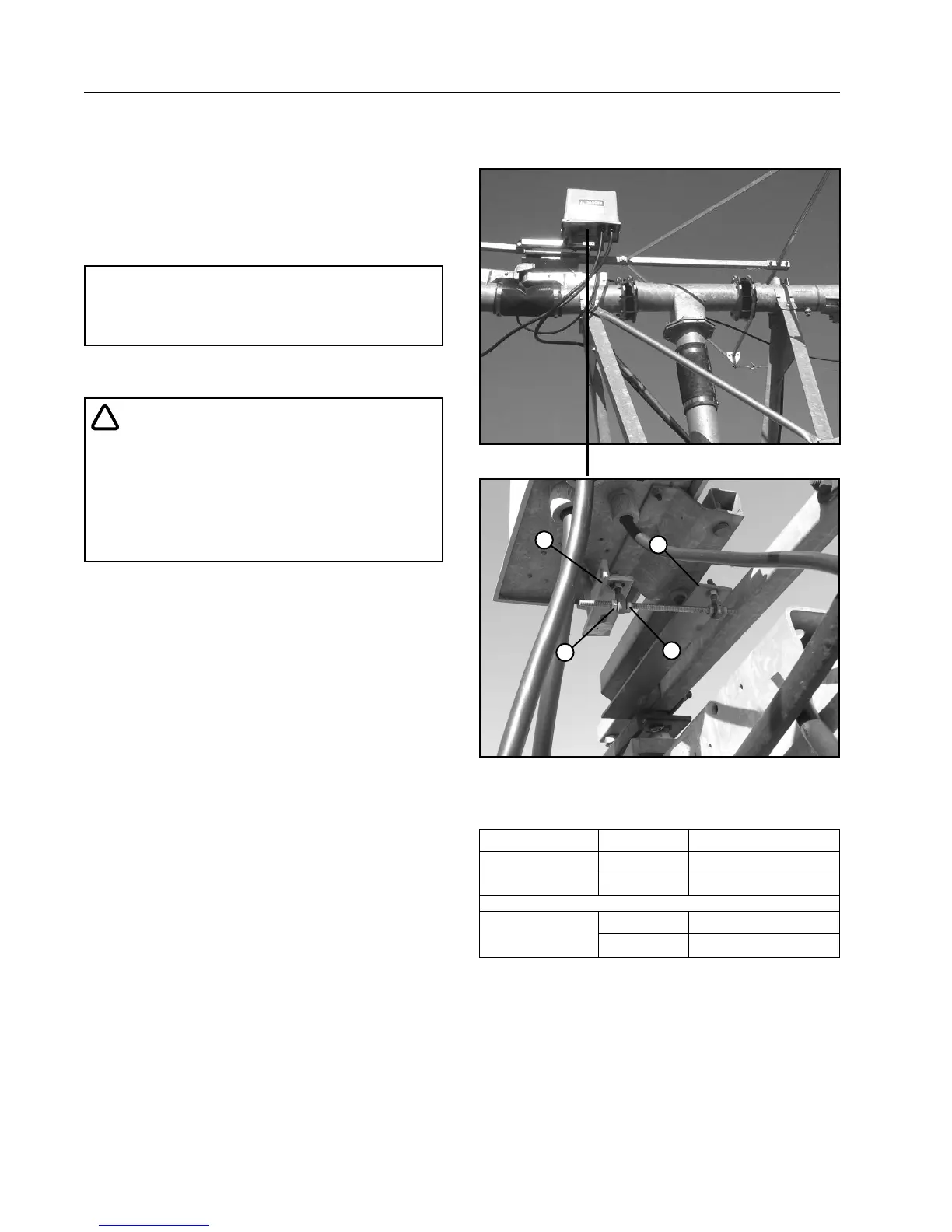

1. Adjust nuts #1 and #2 as needed. Refer to Fig-

ures 86-2 and 86-3.

!

CAUTION

• NEVER ADJUST NUTS #1 AND #2 MORE

THAN 1/4 TURN AT ONE TIME.

• ALWAYS RE-TIGHTEN THE JAM NUTS AND

ALLOW THE TOWER TO CYCLE TWICE

(START AND STOP) TO DETERMINE IF THE

TOWER IS STILL LEADING OR TRAILING.

2. Adjust nuts #1 and #2 until the tower is in align-

ment.

3. Continue the Three Tower Method of alignment

down the entire length of the machine making

adjustments as necessary to individual towers.

Figure 86-1

Clockwise

Counter-clockwise

1

2

3

4

1

2

3

4

Figure 86-2 1. Nut

2. Nut

3. Yoke Control Rod

4. Switch Pivot Arm

Direction of travel Condition Adjust Nuts

Forward

Leading Bow **Counter-clockwise

Trailing Bow *Clockwise

Reverse

Leading Bow *Clockwise

Trailing Bow **Counter-clockwise

ADJUSTMENT CHART

Figure 86-3 * Clockwise - Adjust the nut further onto the

threaded rod.

** Counter-clockwise - Back the nut off the

threaded rod as if removing it.

Loading...

Loading...