2.5 Connecting Power to Liqui-tect

WARNING! Liqui-tect LP6000 requires a dedicated circuit breaker that is clearly marked as the

disconnection device for the [[[Undefined variable Liquitect.ModelNo]]] controller. Make sure

that the dedicated circuit break is off before connecting the AC power wires to the

[[[Undefined variable Liquitect.ModelNo]]] controller. Follow all state and local codes.

1. Engage a certified electrician to run an isolated power supply to the location of the unit.

2. Remove knockouts, as necessary, from the bottom of the unit, then route the power supply into

the enclosure to the power-input terminal block, and insert the wires a shown on the back

plate: Neutral - Line - Ground, see Input and Output Connectors on page 10.

3. Before applying power to the unit, make sure that all connections are correct and all screw

terminals are secure.

4. Apply power and wait approximately 1minute for the LP6000 to start up.

There may be alarms because the leak-detection cable is not yet connected.

5. Verify that power is connected, and verify that the leak-detection cable is working by touching

it with a clean, moist cloth or paper towel.

If the cable is properly connected, an audible alarm sounds and an alarm notification displays

on the digital display.

NOTE: Do not saturate the leak-detection cable for testing. A small amount of water triggers an alarm,

and the cable must dry for the alarm to clear.

6. Dry the cable to remove the alarm condition. Use a hair dryer to speed up drying if needed.

7. Once you verify that the leak-detection cable is working, you are ready to calibrate the cable,

map leak-detection points and test the installation. See Mapping and Testing the Installation

on page 16.

2.6 Calibrating Resistance to Cable Length

The leak-detection cable has a base resistance of 4 ohms/ft. Because of manufacturing variances, the

base resistance of each length of leak-detection cable may be slightly more or less than 4 ohms/ft, which

means that the displayed length may be slightly more or less than the actual length of the cable.

While a configuration using base resistance values is very accurate, you can fine-tune the resistance to

make it more precise to increase accuracy and bring the reported cable-length value in line with the

actual cable length.

To calibrate cable resistance:

1. Make sure that the LP6000 controller is powered-on, has all sensing cables attached, and that

there are no alarms.

2. Record the following data from the home page of the web UI:

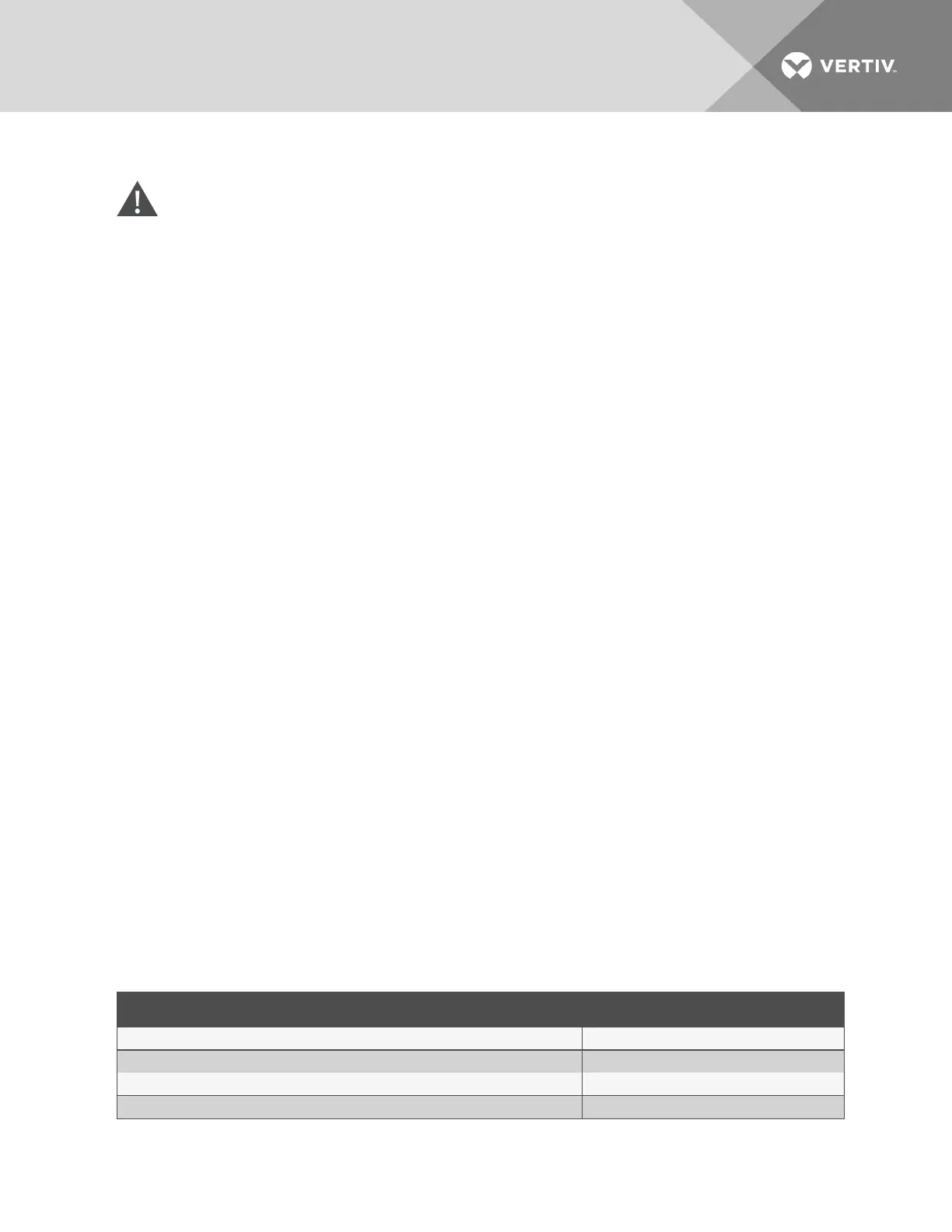

DATA RECORDED INFO

Cable length reported by LP6000.

Cable current

Leg 1 resistance

Leg 2 resistance

Vertiv | Liqui-tect LP6000 Installer/User Guide | 15

Loading...

Loading...