VESDA Maintenance Guide VESDA

6 www.xtralis.com

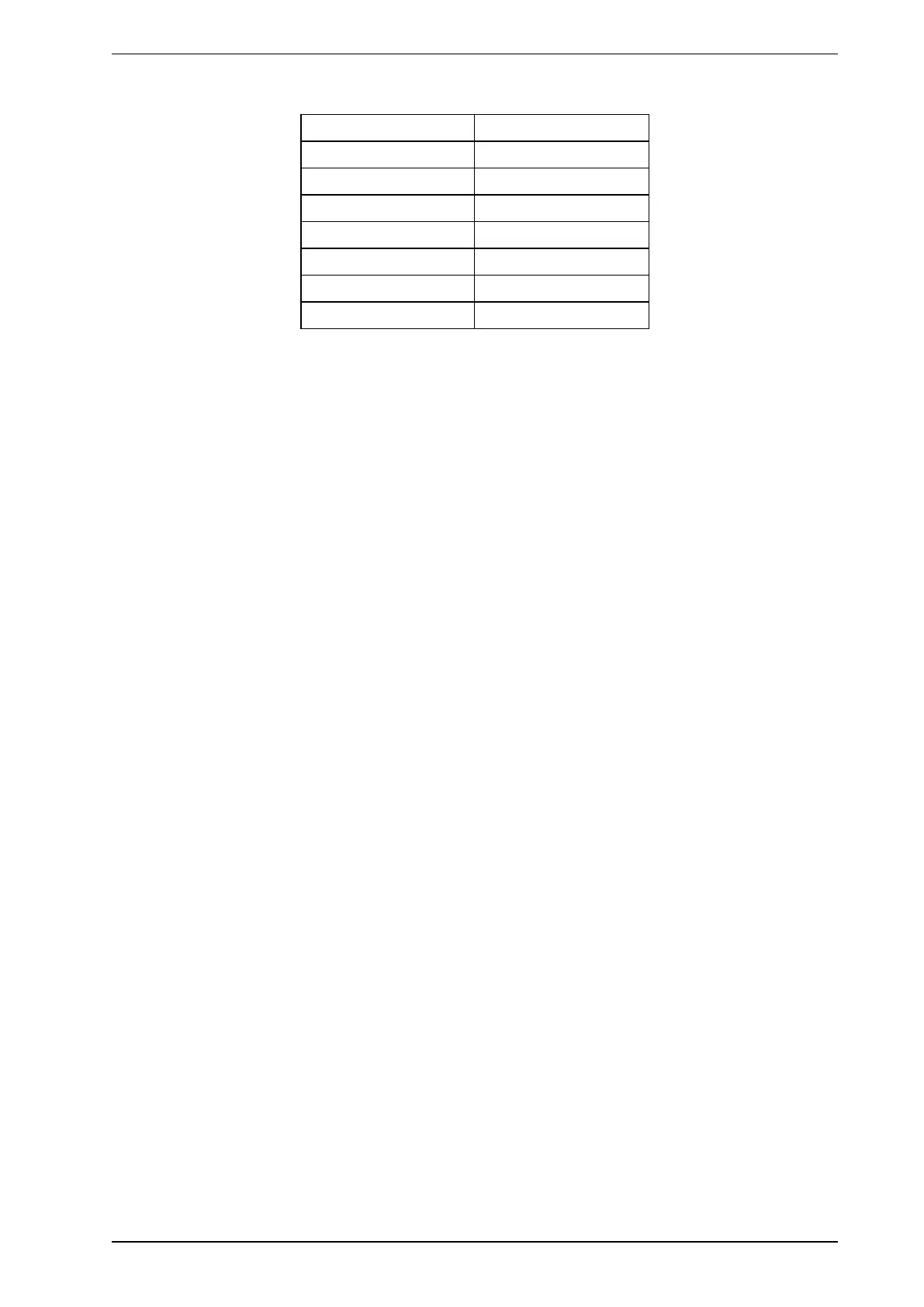

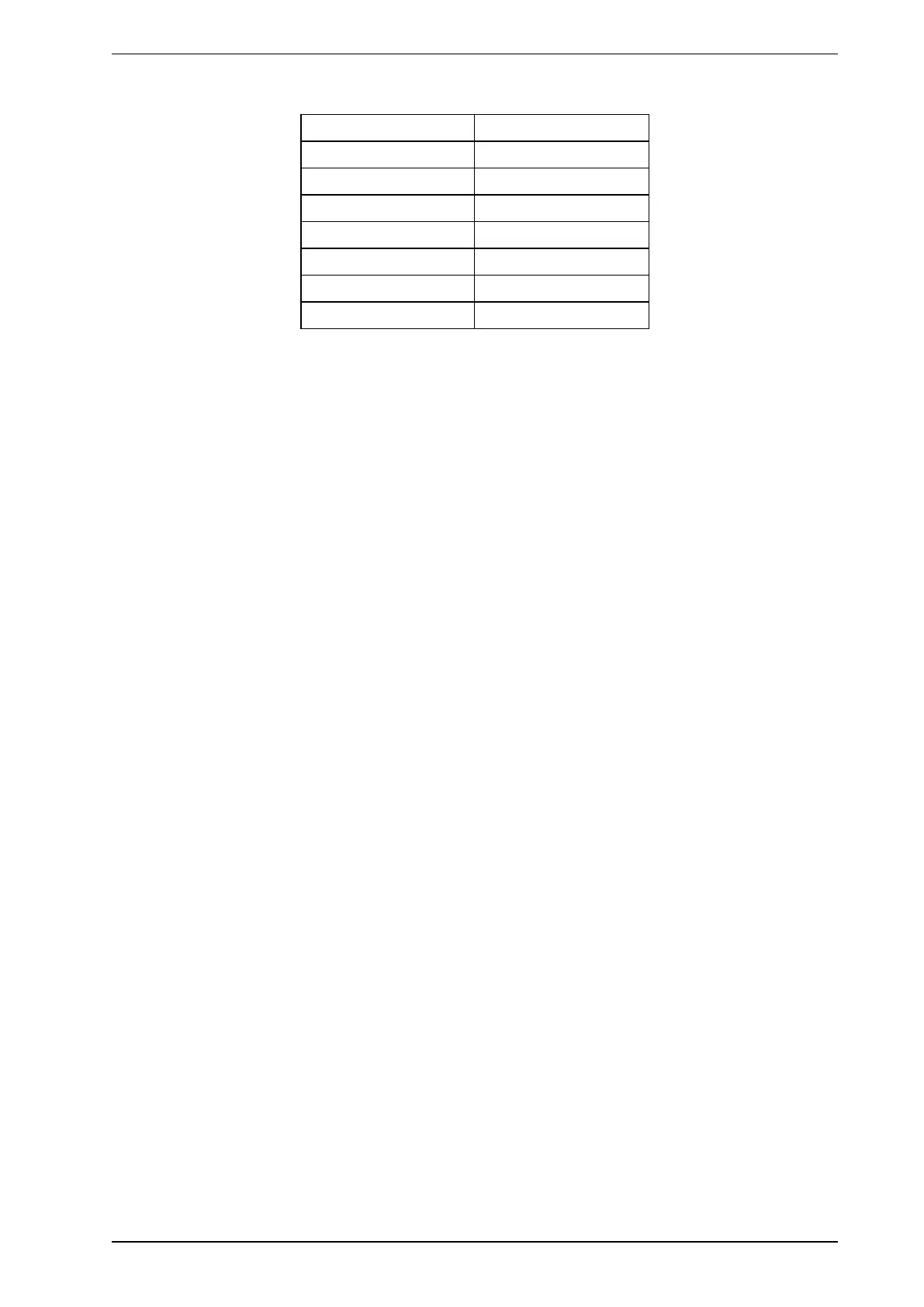

Table 2-1: Color codes for filter date of manufacture (VSP-005 filters)

Color Date

Purple March 2014

Red August 2011

Brown July 2008

Yellow July 2006

Green July 2004

Orange July 2000

Blue July 1997

4. Check for and record any detector faults.

5. Prior to downloading the smoke event log, use Xtralis VSC to check the significant smoke change

setting. If it is still at the factory default value of 0.02%obs/m (0.0063%obs/ft) or some other value, record

it then change it to 0.005%obs/m (0.0015%obs/ft).

6. Run the detector for 15 minutes minimum (longer is recommended in very stable or clean environments).

7. Download and save the event log for comparison of smoke readings during normal operation.

8. Determine the detector's background smoke level and estimate the average recorded level, for typical

operation, during the test period.

9. Compare the results with Appendix B on page 49 to determine your system's environment class.

10. Based on your system's environment class, establish an appropriate detector and filter maintenance

schedule.

11. Using Xtralis VSC, set the filter service timer to the value, in days, given in Appendix B on page 49.

12. Using Xtralis VSC, return the significant smoke change setting to its original value.

13. Proceed to the next section or, if your system is showing no faults, return it to its normal operating mode.

2.3 Unscheduled Maintenance

There will be occasions where unscheduled detector maintenance is required. Such instances are often the

result of fault conditions. Faults can range from minor to urgent and must be dealt with by trained and qualified

personnel. A full investigation of any reported fault must be conducted, taking into account all possible causes

of the fault.

For further information, refer to the VESDA Troubleshooting Guide in the System Design Manual or visit

www.xtralis.com.

Loading...

Loading...