4.8 Sound emission

The actual sound emission of the machine varies

heavily depending on the manufacturing material and

the machining conditions.

If the machine is exceptionally loud, check the fol-

lowing operating conditions:

n

Cleanliness of the blank holder

n

Condition of the tools

n

Quality of the blanks

If loud noise cannot be avoided, wear ear protection

during machining.

Sound measurement

Measuring conditions:

n

Processed material: IPS e.max (block, C14)

n

Tool status: new

n

Measured value: sound pressure level (distance:

1m)

n

Measurement according to ISO 3746, survey

method 3

Established sound emission:

Operating condition

A-weighted

sound pres-

sure level

A-weighted

sound

power level

Processing 69.8 dB(A) 80.6 db(A)

All other operating condi-

tions (tool change, move-

ment of the axes etc.)

<70 dB(A) –

4.9 Location of the identification

plate & serial number

The identification plate of the machine contains identi-

fying information such as the serial number. You can

find the identification plate and machine serial number

at the following location: Rear side of the machine – on

page10

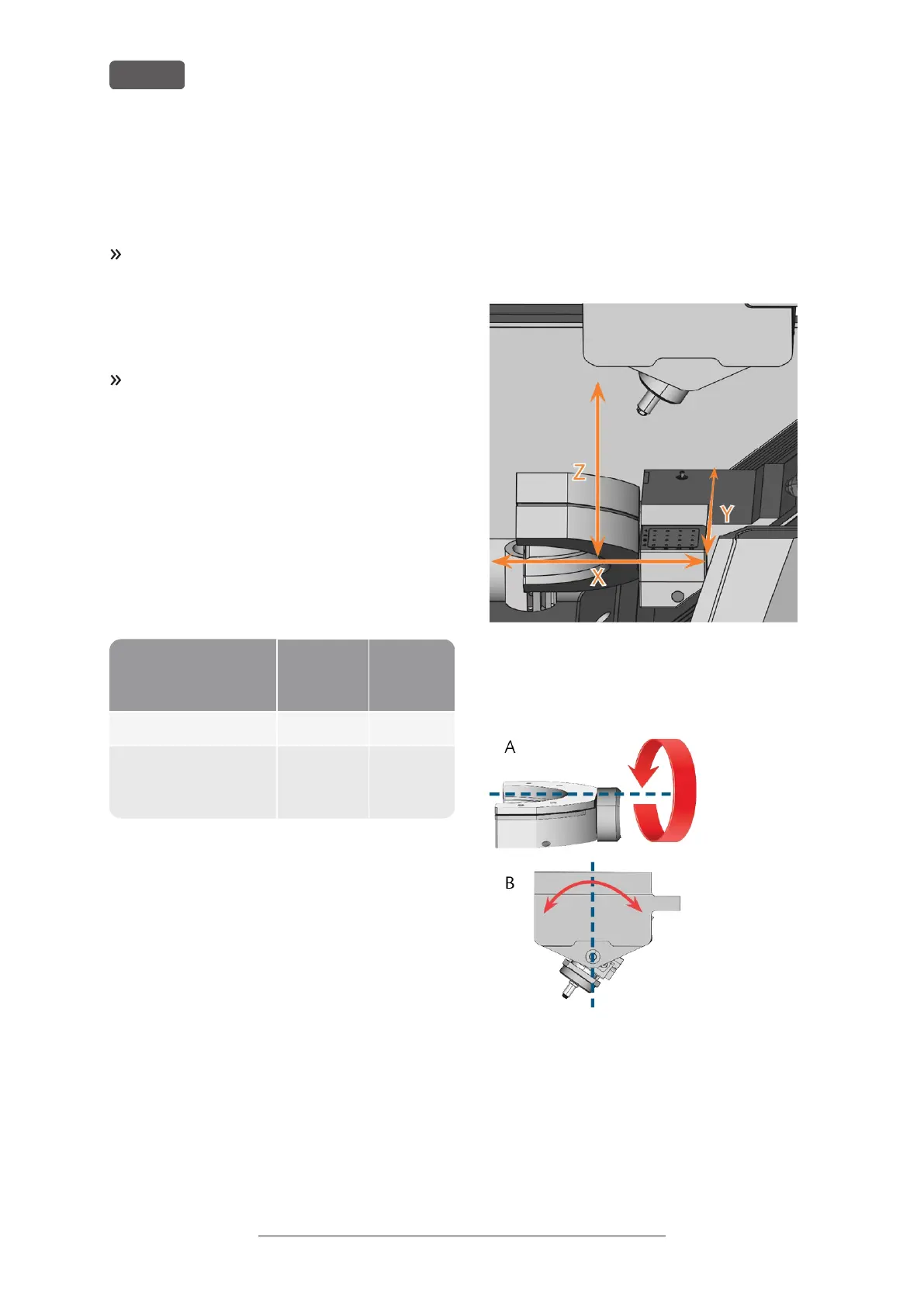

4.10 Axes

This machine has 5 axes: 3 linear axes and 2 rotary

axes.

4.10.1 Linear axes

The spindle moves along these axes.

FIG. 6 R5:LINEAR AXES

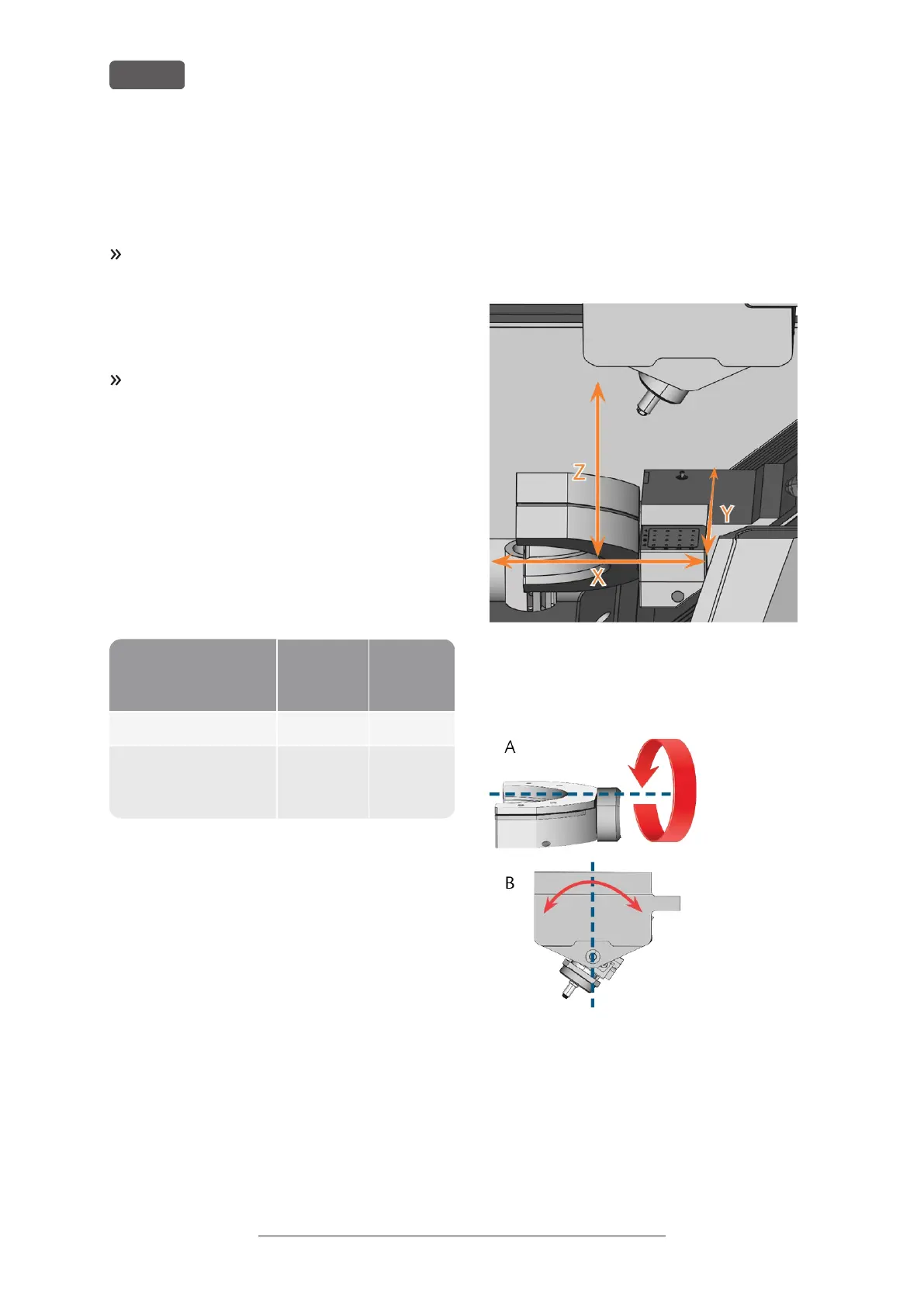

4.10.2 Rotary axes

The blank holder rotates about these axes.

FIG. 7 R5: ROTARY AXES

Original Operating Instructions:R5

Version: 12/16/2021

R5 – Machine overview

EN 14

Loading...

Loading...