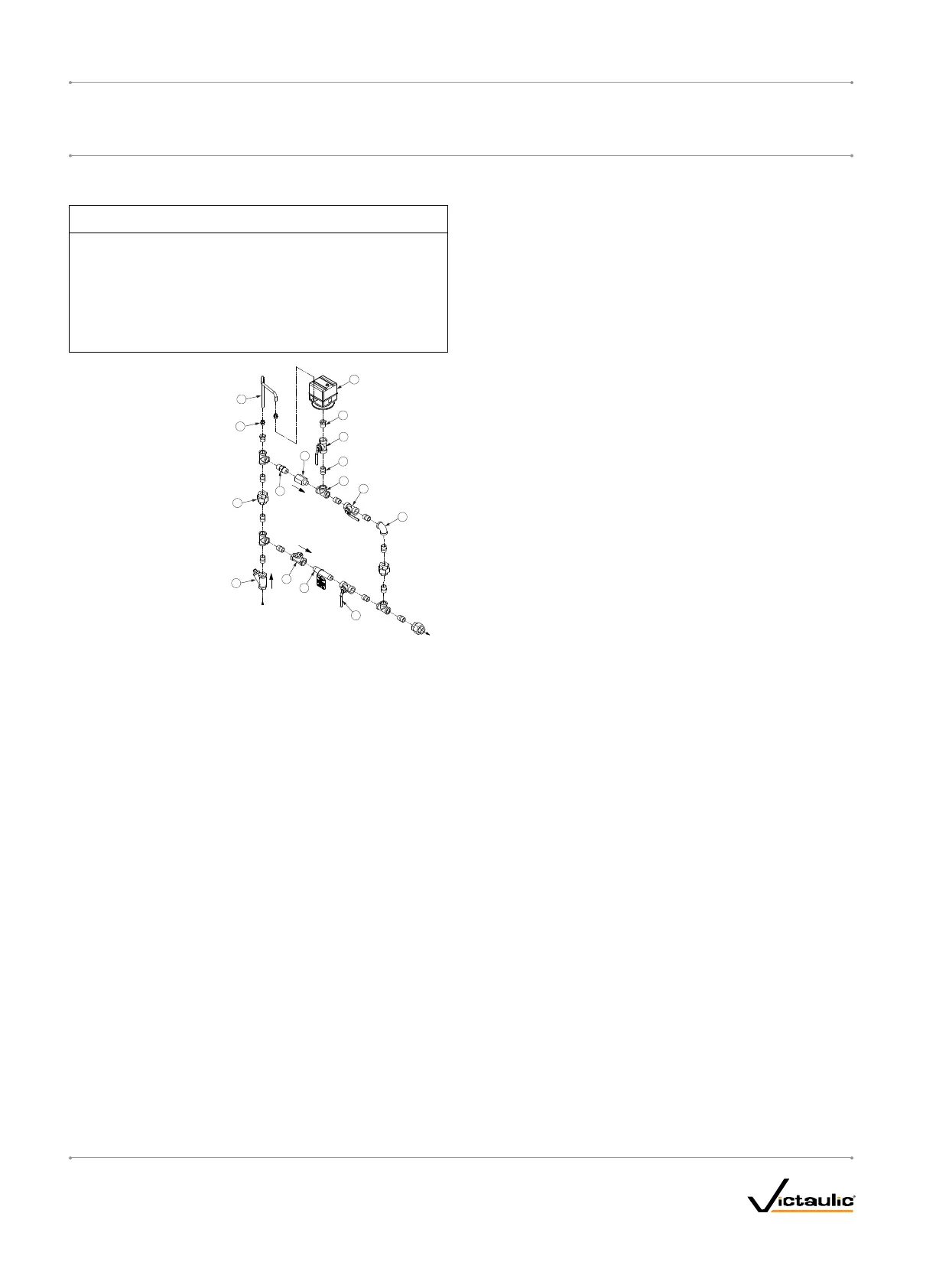

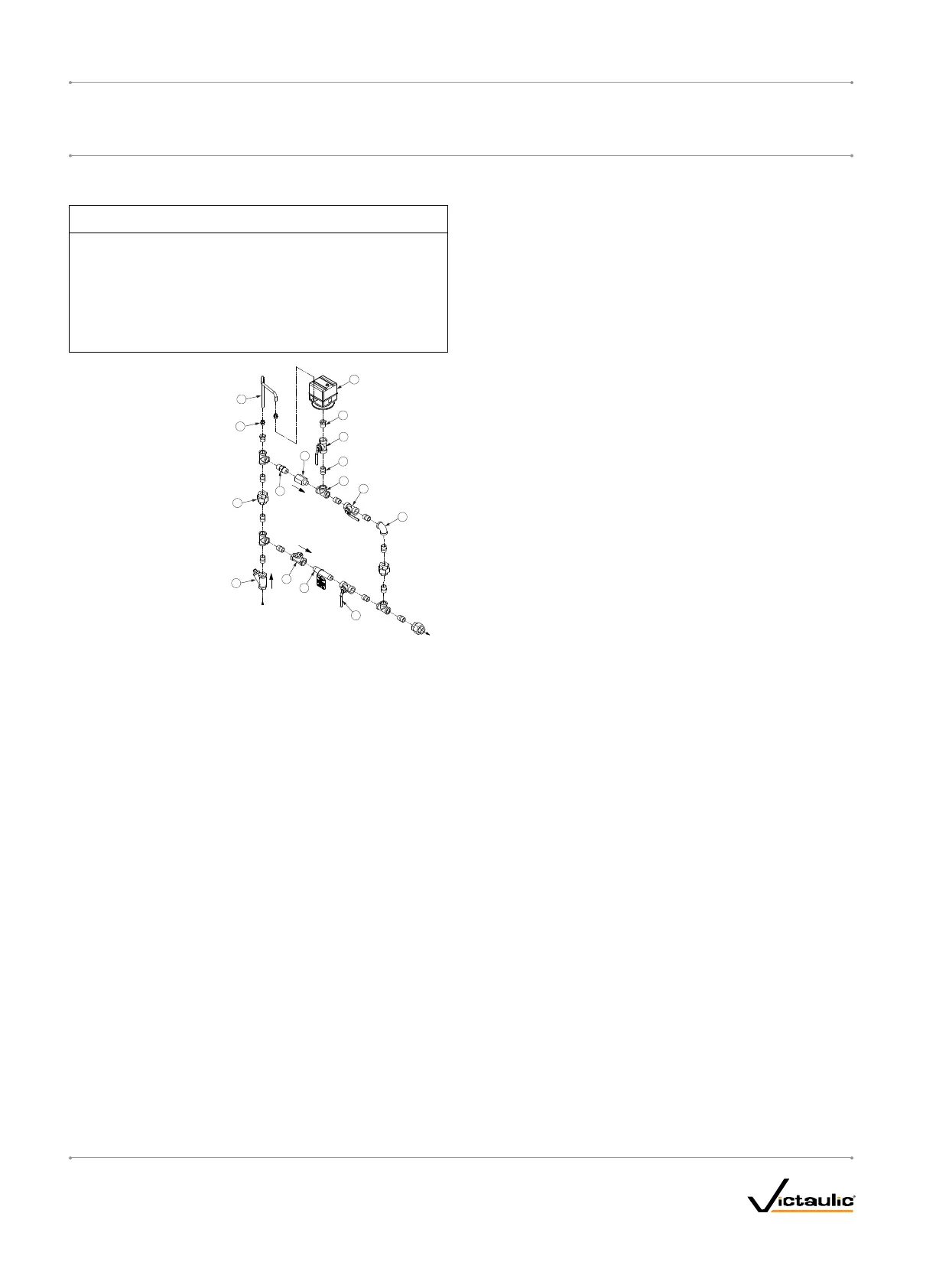

VICTAULICSERIES757PAIRMAINTENANCETRIMASSEMBLY

(AMTA)WITHPRESSURESWITCHOPTION

NOTICE

VictaulicrecommendsamaximumoftwoSeries768FireLock•

NXTDryValvesperSeries757PAMTAwithPressureSwitch.

RefertotheI-757PAirMaintenanceTrimAssemblywith•

PressureSwitchInstallationInstructions,suppliedwiththe

product,forcompleteinstallation,electrical,andpressure

switchadjustmentinformation.

5

2

12

7

8

15

10

16

9

6

4

1

13

3

14

11

TO

SYSTEM

FROM

COMPRESSOR

Bill of Materials

Item Qty. Description

1 1 Restrictor (½-inch NPT)

2 1 Strainer (½-inch NPT)

3 1 Swing Check (½-inch NPT)

4 1 Slow-Fill Ball Valve

(Normally Open)

5 1 Spring-Loaded, Soft-Seated

Check Valve

6 1 Pressure Switch

7 2 Compression Fitting, Straight

(¼-inch NPT x ¼-inch Tube)

8 1 Copper Tubing (¼-inch OD)

9 11 Close Nipple

(½-inch NPT x 1.13)

10 1 Nipple (½-inch NPT x 4.00)

11 1 90° Female Elbow (½-inch NPT

12 4 Female Tee (½-inch NPT)

13 3 Union (½-inch NPT)

14 2 Reducing Bushing

(½-inch NPT x ¼-inch NPT)

15 1 Fast-Fill Ball Valve

(Normally Closed)

16 1 Pressure Switch Isolation Ball

Valve (Normally Open -

Lockable)

COMPRESSORREQUIREMENTSANDSETTINGSFORSERIES768

FIRELOCKNXTDRYVALVESINSTALLEDWITHSERIES746-LPA

DRY ACCELERATORS

Set the air regulator of the Series 757 Regulated AMTA to a minimum of

13 psi/90 kPa/0.9 Bar.

FORVdSAPPROVEDVALVESONLY: The minimum air pressure for

Series 768 FireLock NXT Dry Valves installed with Series 746-LPA Dry

Accelerators shall be 16 psi/110 kPa/1.1 Bar. The maximum air pressure

shall be 19 psi/130 kPa/1.3 Bar.

TheSeries757PAirMaintenanceTrimAssemblywithPressure

SwitchMUSTNOTbeusedonaSeries768FireLockNXTDryValve

installedwithaSeries746-LPADryAccelerator,unlessatankandair

regulatorareadded.

In the event a compressor becomes inoperative, a properly sized tank-

mounted air compressor provides the greatest protection for systems

installed with a Series 746-LPA Dry Accelerator. In this situation, air

can be supplied continuously to the sprinkler system for an extended

time period. NOTE: The Series 757 Regulated AMTA should be used

with a tank-mounted air compressor to supply air to a Series 768

FireLock NXT Dry Valve when the Series 746-LPA Dry Accelerator

is used. The use of an air regulator with a base or riser-mounted air

compressor could cause short cycling, resulting in premature wear of

the compressor.

The air regulator of the Series 757 Regulated AMTA is a relief-type

design. Any pressure in the system that is above the set point of the air

regulator will be released. Therefore, charging the air regulator above

the set point could cause premature operation of a valve installed with a

Series 746-LPA Dry Accelerator.

SETTINGSFORAIRSUPERVISORYPRESSURESWITCHESAND

ALARMPRESSURESWITCHES

1. Air supervisory pressure switches are required for dry systems and

must be set according to the following notes. NOTE: Switches for

Vic-Quick Risers are pre-set at the factory.

1a. Wire the air supervisory pressure switches to activate a

low-pressure alarm signal. NOTE: In addition, the local

authority having jurisdiction may require a high-pressure

alarm. Contact the local authority having jurisdiction for this

requirement.

1b. Set the air supervisory pressure switches to activate at

2 – 4 psi/14 – 28 kPa/0.1 – 0.3 Bar below the minimum air

pressure required (but not lower than 10 psi/69 kPa/0.7 Bar).

1c. Wire the alarm pressure switch to activate a water flow alarm.

1d. Set the alarm pressure switch to activate on a pressure rise of

4 – 8 psi/28 – 55 kPa/0.3 – 0.6 Bar.

REMOTESYSTEMTESTVALVEREQUIREMENTS

The remote system test valve (inspector’s test connection) should

contain a UL Listed and/or FM Approved valve (normally closed), which

can be opened to simulate the operation of a sprinkler.

The remote system test valve (inspector’s test connection) should be

located at the most hydraulically demanding location in the release

system. NOTE: Multiple restrictions on the remote system test valve

(inspector’s test connection) may slow the air decay rate and cause the

system to respond slower than required.

The remote system test valve (inspector’s test connection) should

terminate with an orifice equal to the smallest orifice in the releasing

system.

The remote system test valve (inspector’s test connection) is used to

ensure that water reaches the most remote part of the system within 60

seconds.

I-768_10

FireLockNXT™DryValve

SERIES768

I-768

INSTALLATION,MAINTENANCE,ANDTESTINGMANUAL

www.victaulic.com

VICTAULIC IS A REGISTERED TRADEMARK OF VICTAULIC COMPANY. © 2007 VICTAULIC COMPANY. ALL RIGHTS RESERVED. PRINTED IN THE USA.

REV_D

Loading...

Loading...