IMPORTANTINSTALLATIONINFORMATION

1. For proper operation and approval, the Series 768 FireLock NXT

Dry Valve must be installed in accordance with the specific trim

diagrams included with the shipment. NOTE: Victaulic provides

specific trim diagrams for installations involving a Series 746-LPA

Dry Accelerator.

2. Before installing the Series 768 FireLock NXT Dry Valve, flush the

water supply piping thoroughly to remove all foreign material.

3. Series 768 FireLock NXT Dry Valves MUST NOT be located in an

area where the valve can be exposed to freezing temperatures. In

addition, the Series 768 FireLock NXT Dry Valve MUST NOT be

located in an area where physical damage may occur.

4. It is the system designer’s responsibility to confirm material

compatibility of the Series 768 FireLock NXT Dry Valve, trim,

and associated accessories when a corrosive environment or

contaminated water is present.

5. SERIES768FIRELOCKNXTDRYVALVESMUSTBE

INSTALLEDONLYINTHEVERTICALPOSITIONWITHTHE

ARROWONTHEBODYPOINTINGUPWARD.

6. Air or nitrogen supply to the dry piping system must be clean, dry,

and oil-free.

7. Air supplies must be regulated, restricted, and continuous.

8. When an uninterruptible water flow alarm is required, Victaulic

recommends the use of a low-pressure alarm installed on the

diaphragm charge line downstream of the strainer/check restrictor.

Another option is to install a Series 75B Supplemental Alarm

Device.

9. Per NFPA 13 requirements, piping must be pitched so that

systems can drain properly. For areas that are subject to high

levels of condensation, or where piping is not properly pitched, an

optional Series 75D Water Column Device kit is available to assist

in a utomatically draining water out of the riser.

VALVE/TRIMINSTALLATION

1. Make sure the trim drawing matches the system’s requirements.

CAUTION

Makesurethefoamspacerisremovedfrom•

insidethevalvebodybeforeattemptingto

installthevalve.

Failuretofollowthisinstructioncouldcause

impropervalveoperation,resultinginpersonal

injuryand/orpropertydamage.

2. Remove all plastic caps and foam spacers from the valve.

3. Apply a small amount of pipe joint compound or Teflon* tape to

the external threads of all threaded pipe connections. DO NOT get

any tape, compound, or other foreign material into the valve body,

pipe nipples, or valve openings.

CAUTION

Makesurenoforeignmaterialgetsintothevalvebody,pipe•

nipples,orvalveopenings.

IfusinganymaterialotherthanTeflontape,useextracaution•

sothatnomaterialgetsintothetrim.

Failuretofollowtheseinstructionscouldcauseimpropervalve

operation,resultinginpersonalinjuryand/orpropertydamage.

4. Install the valve, trim, and accessories per the trim drawing.

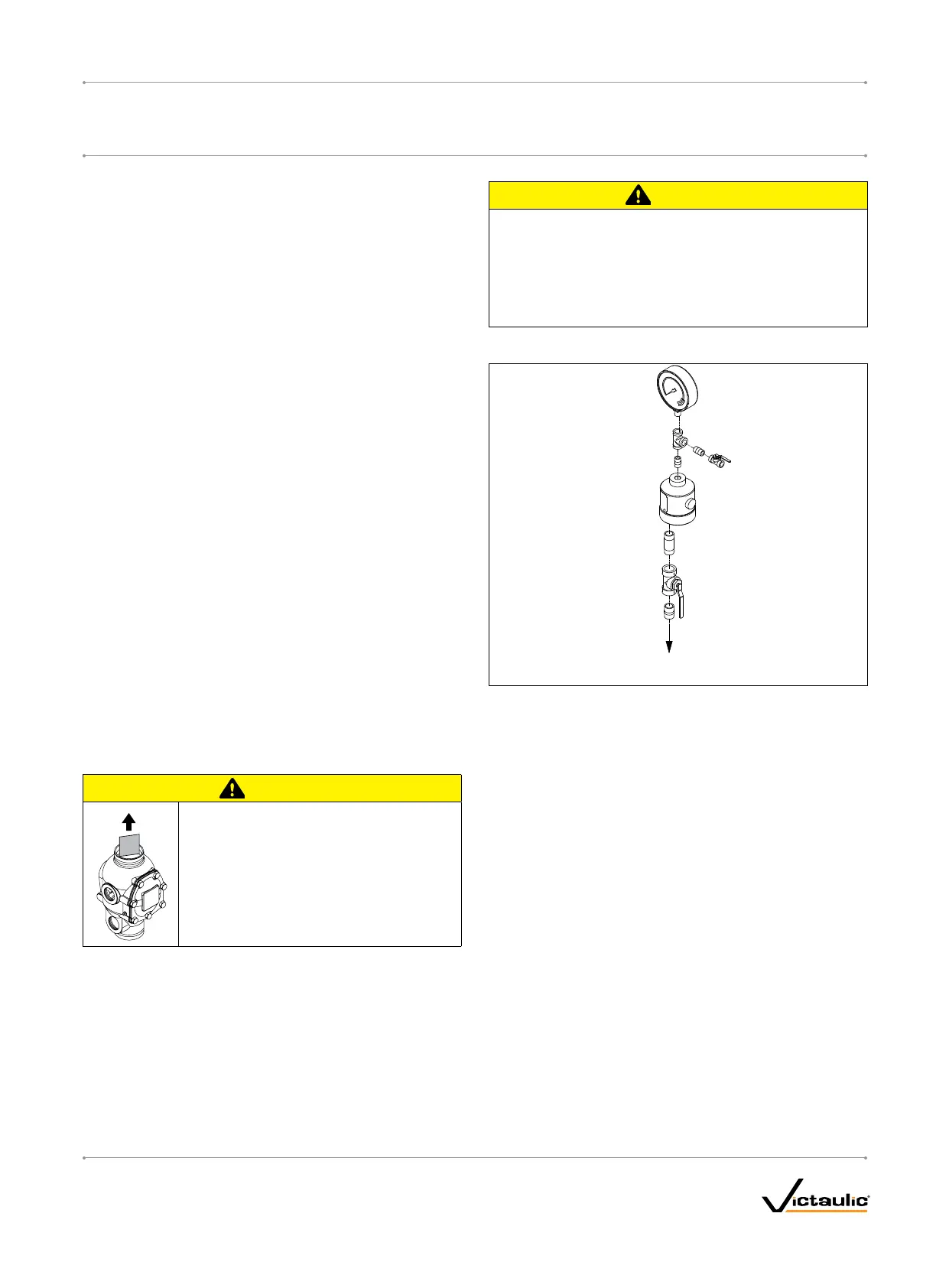

TO ACTUATOR

TRIM

5. FORVALVESINSTALLEDWITHASERIES746-LPADRY

ACCELERATOR:Make sure the Series 746-LPA Dry Accelerator is

installed in accordance with the trim drawing provided. The end

with the vent seal “button” must be installed facing down (toward

the trim, as shown above).

6. Supply pressure to the diaphragm charge line by providing an

uninterrupted source of water from upstream of the main control

valve.

* Teflon is a registered trademark of the DuPont Company

I-768_11

FireLockNXT™DryValve

SERIES768

I-768INSTALLATION,MAINTENANCE,ANDTESTINGMANUAL

www.victaulic.com

VICTAULIC IS A REGISTERED TRADEMARK OF VICTAULIC COMPANY. © 2007 VICTAULIC COMPANY. ALL RIGHTS RESERVED. PRINTED IN THE USA.

REV_D

Loading...

Loading...