MAINTENANCE

The following sections instruct on how to remove and replace internal

valve components. Care must be taken to avoid damage to parts during

removal and installation.

WARNING

Depressurizeanddrainthepipingsystem•

beforeattemptingtoremovethecoverplate

fromthevalve.

Failuretofollowthisinstructioncouldresult

inseriouspersonalinjuryand/orproperty

damage.

CAUTION

Anyactivitiesthatrequiretakingthe•

valveoutofservicemayeliminatethefire

protectionprovided.

Beforeservicingortestingthesystem,•

notifytheauthorityhavingjurisdiction.

Considerationofafirepatrolshouldbe•

givenintheaffectedareas.

Failuretofollowtheseinstructionscould

resultinseriouspersonalinjuryand/or

propertydamage.

RemovingandReplacingtheClapperSeal

1. Perform steps 1 – 13 of the “Required Internal Inspection” section.

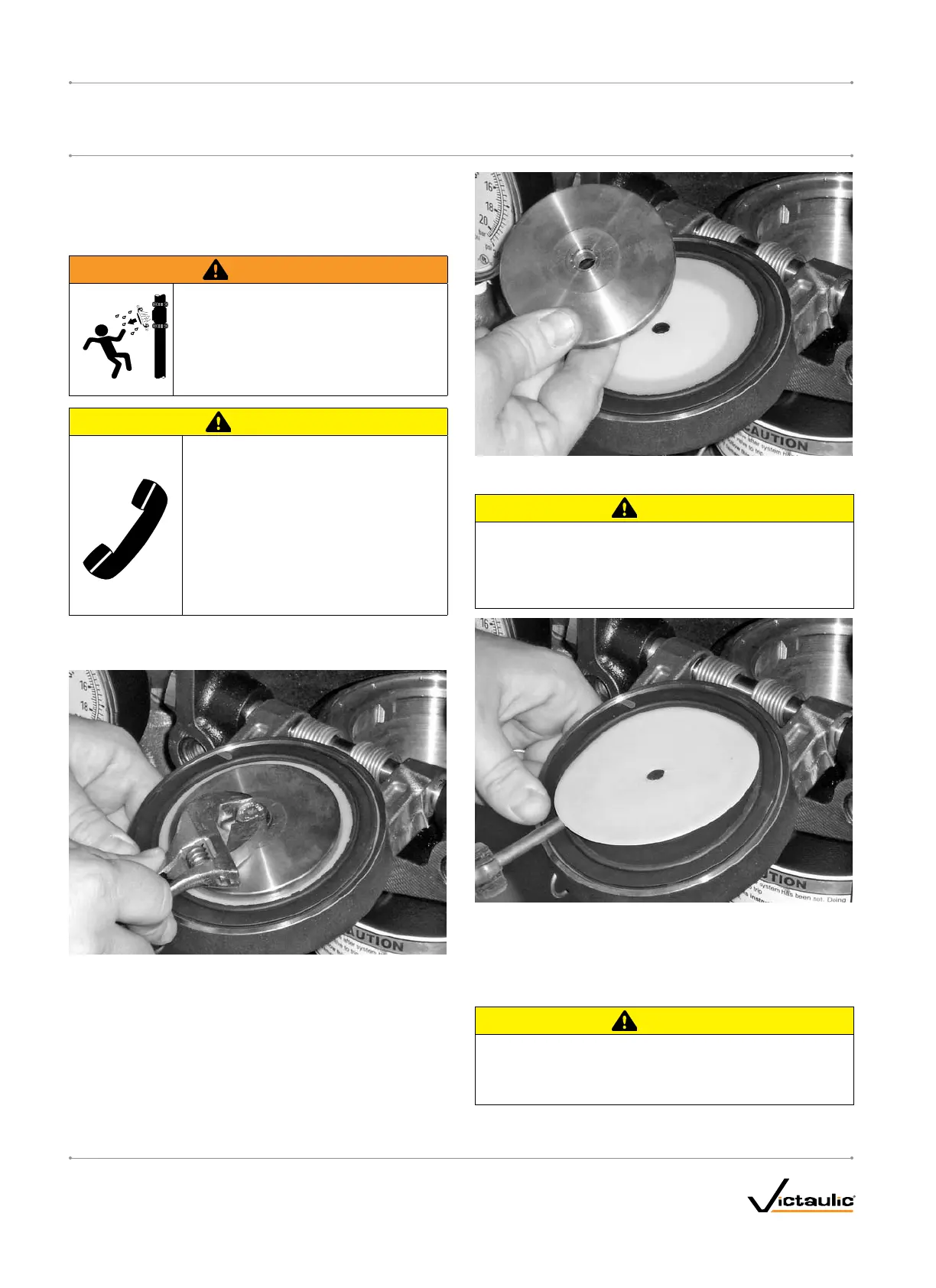

2. Remove the seal assembly bolt/bolt seal from the clapper seal.

3. Remove the seal-retaining ring.

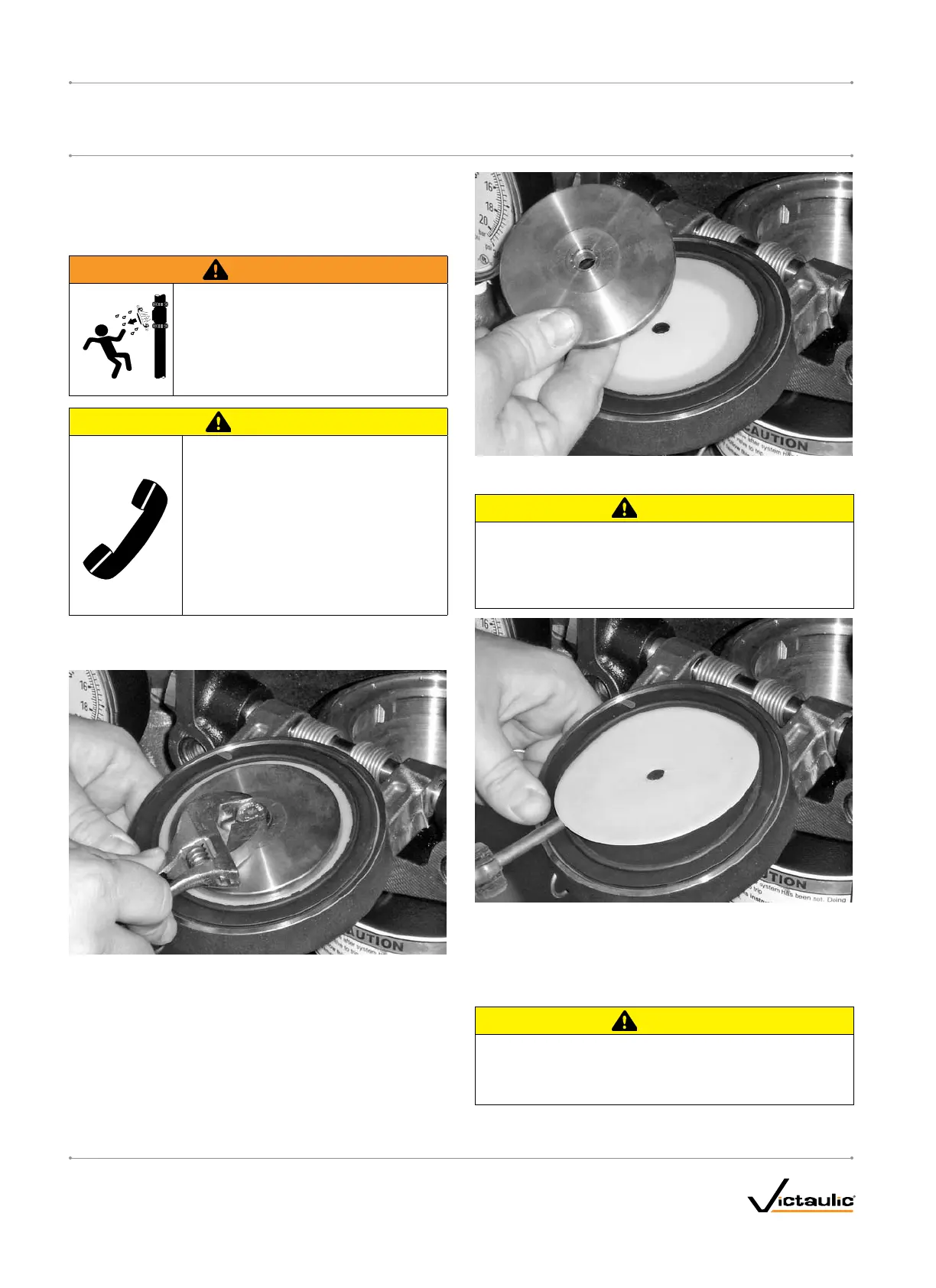

CAUTION

DONOTprythesealwasheroutoftheclappersealfromthe•

innerhole.

Failuretofollowthisinstructioncoulddamagethesealwasher,

resultinginimproperclappersealingandvalveleakage.

4. Pry the edge of the seal washer from inside the clapper seal, as

shown above. DONOTPRYTHESEALWASHEROUTFROM

THEINNERHOLE.

5. Remove the seal washer from the clapper seal. Dry up any

moisture that is under the seal washer and on the clapper seal.

CAUTION

UseonlyVictaulic-suppliedreplacementparts.•

Failuretofollowthisinstructioncouldcauseimpropervalve

operation,resultinginpropertydamage.

I-768_32

FireLockNXT™DryValve

SERIES768

I-768INSTALLATION,MAINTENANCE,ANDTESTINGMANUAL

www.victaulic.com

VICTAULIC IS A REGISTERED TRADEMARK OF VICTAULIC COMPANY. © 2007 VICTAULIC COMPANY. ALL RIGHTS RESERVED. PRINTED IN THE USA.

REV_D

Loading...

Loading...