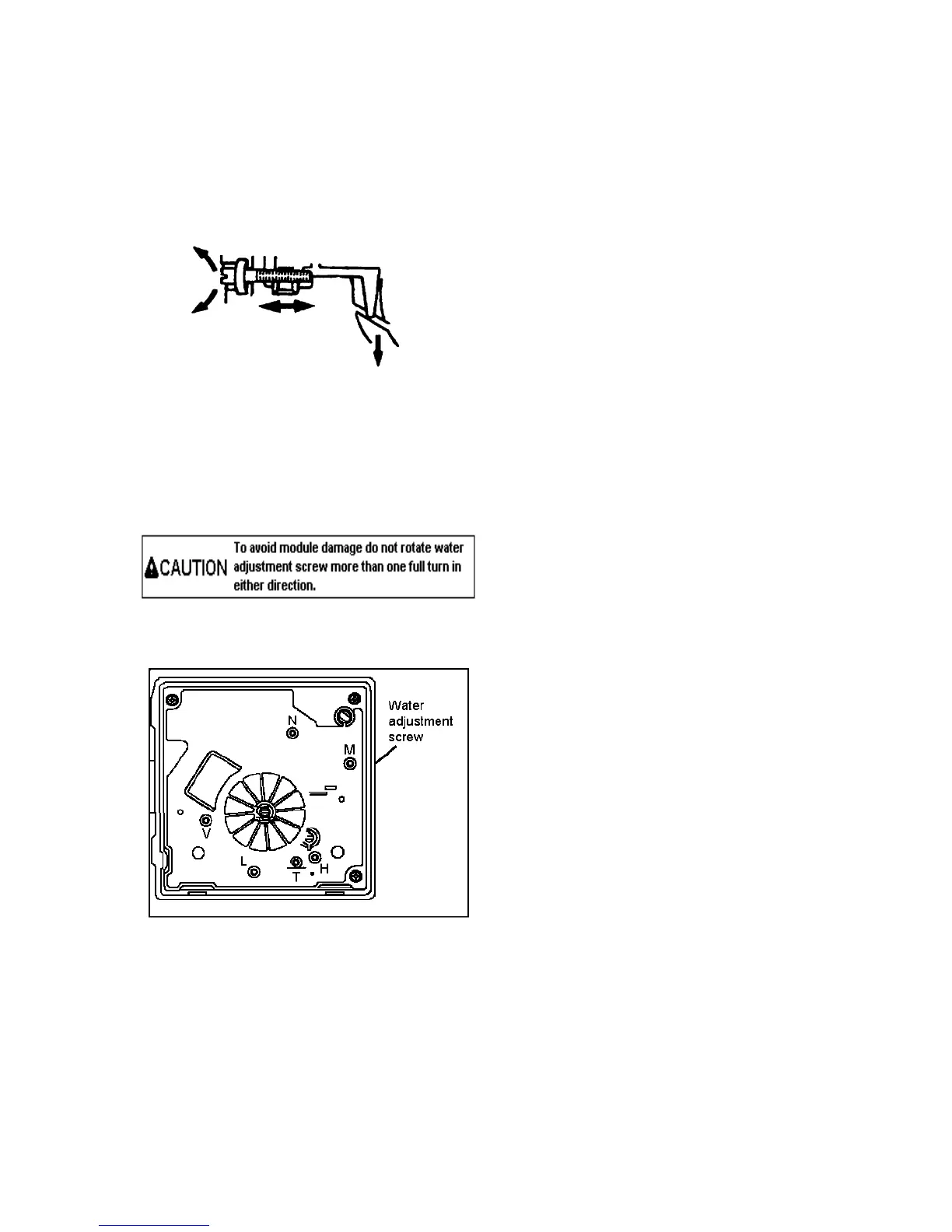

Water Fill Valve

Turning water level adjustment screw will

move contact in relationship with contact

ring segment. This causes contact to vary

time water valve is energized. Contact ring

is tapered at end of fill time.

• Turning screw clockwise decreases fill

time.

• Turning screw counterclockwise

increases fill time.

• ½ turn equals 20 cc or 1.2 seconds.

• Full turn equals 40 cc or 2.4 seconds.

Ice Maker

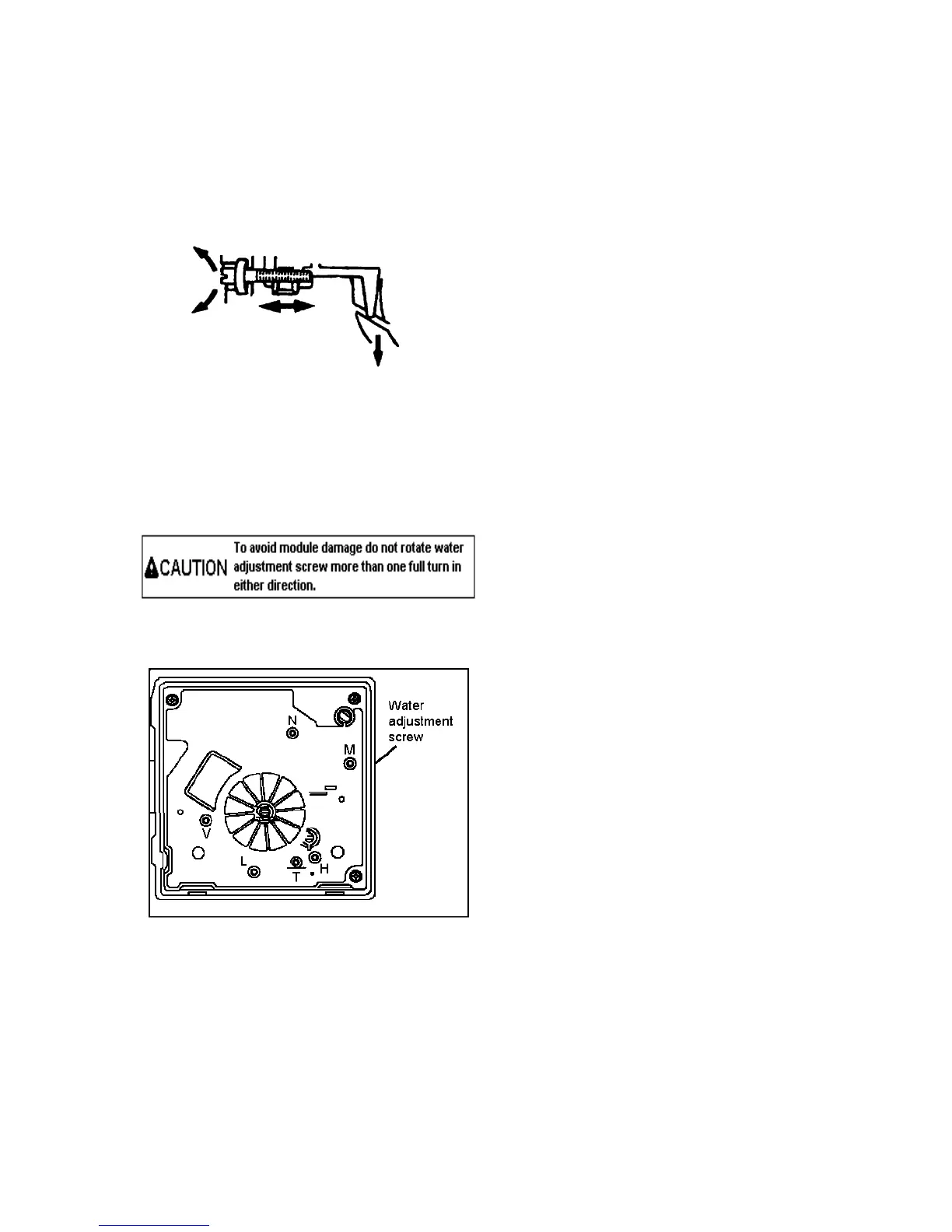

If water valve adjustment screw fall out, put

screw in hole and align as shown below.

When small hole is centered in large hole,

water fill adjustment is 7.5 seconds (normal

fill time).

Water Problems

Poor water quality can cause ice maker to

fail or produce unacceptable cubes. Mineral

content or sand can restrict screen in water

fill valve or particle of sand can keep valve

from seating properly.

If water valve does not close, the following

could occur

• no ice production

• small or hollow ice cubes

• flooding of ice container

Install water filter to eliminate bad taste,

odor, and visible contaminates.

Mineral contact can cause lime build up in

mold,

Wicking of water over mold and poor cube

release can occur. Silicone is applied at

upper edges around fill cup and stripper.

Temperature Problems

Freezer temperatures above normal 0° ± 2° F

(-18°± 1°C) will slow down ice

production. Increase ice production by

setting freezer to colder setting.

Thermostat cycling temperature (1

revolution ice maker) is 17° ± 3° F (-8°

± 1°C). Ice will freeze when these

temperatures are achieved. Cycling time

will be slower if freezer temperature is

not cold enough to achieve mode

temperatures easily.

Thermostat, mold heater, and wiring

harness are replaceable. Any other

failure, including motor, requires

replacement of module assembly.

Replacement mold assembly comes with

new mold heater installed.

50

Loading...

Loading...