7602030

20

160 mm (Fig. 6/b) clear from the handrail of the separating

wall.

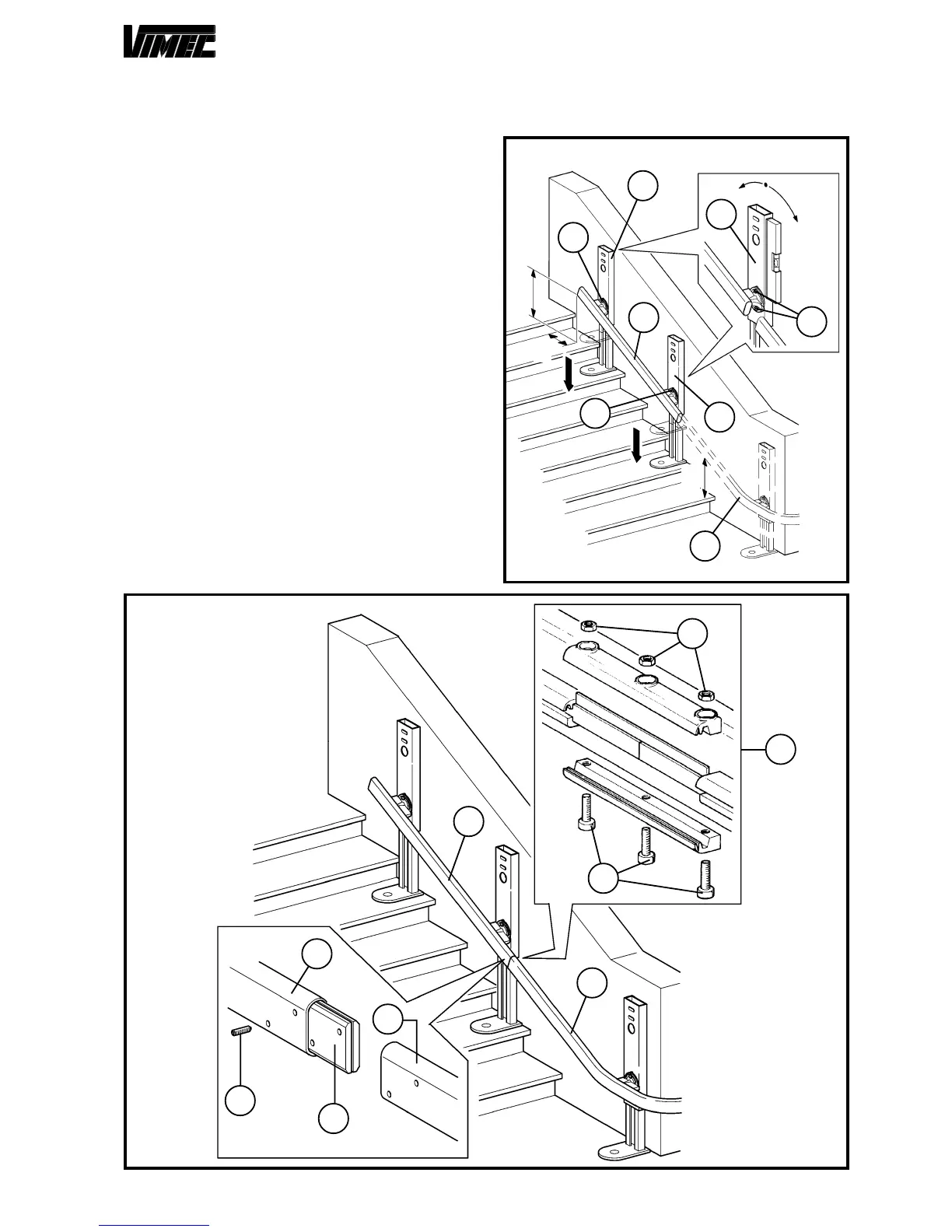

- Put the curve connection devices in vertical position (Fig.

7), tightening both securing screw (Fig. 7/a) at the end of

the adjustment.

CAUTION: The couple for the tightening of the gui-

de securing screws (Fig. 7/a) must be 6-7 daNm.

- Using the proper assembly punching (Fig. 3/b), locate

the guide section with feet (Fig. 8/a) to position right

above the formerly positioned curve (Fig. 8/b).

- Position the guide in the installation point (Fig. 8/a),

taking as reference the values in the assembly diagram

(example see Fig. 5) slide-off the feet and lightly tighten

just one nut (Fig. 8/c) of each connection device (Fig.

8/d).

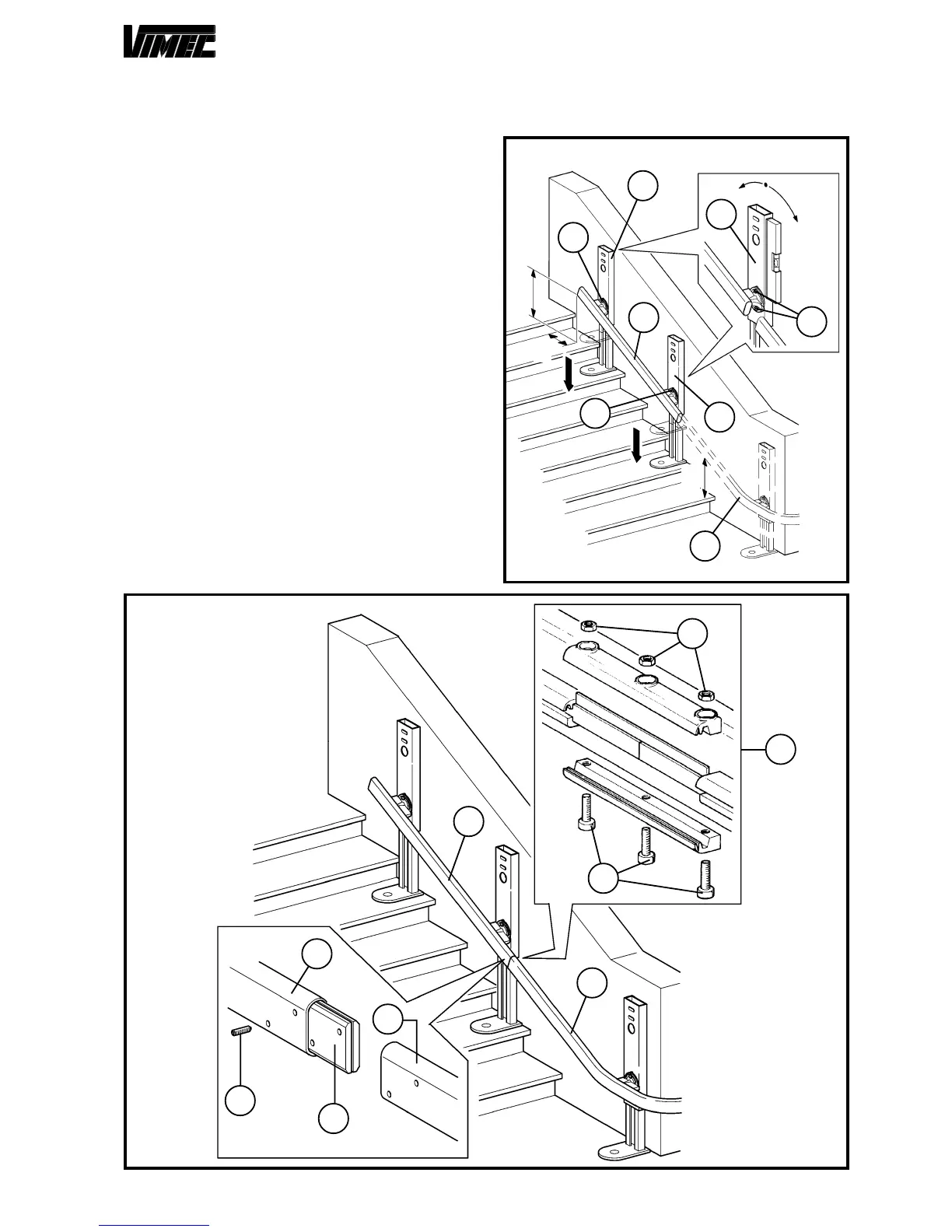

- Insert in the upper guide tube (Fig. 9/a) the joint plates

(Fig. 9/e), screw without tightening the first 2 grub

screws.(Fig. 9/f).

- Draw near the low guide section (Fig. 9/b), assemble

the remaining grub screws and tighten them with a 8-9

daNm couple after verifying the correct tubes alignment

and the lack of space between one tube and the other.

Assemble the bus-way joint as shown in figure (Fig. 9/

d) after verifying the components cleanliness.

- As already done for the curve, set the connection

devices in perfectly vertical position (Fig. 8/e), tightening

both securing screws (Fig. 8/f) at the end of the

adjustment.

- Carry out the installation of all guide sections except

the last one as formerly described down to the bottom

of the scale.

FIG.8

C

D

A

± 1°

max

e

f

d

a

b

c

d

c

FIG.9

h

g

d

c

c

e

b

f

a

Loading...

Loading...