7602030

21

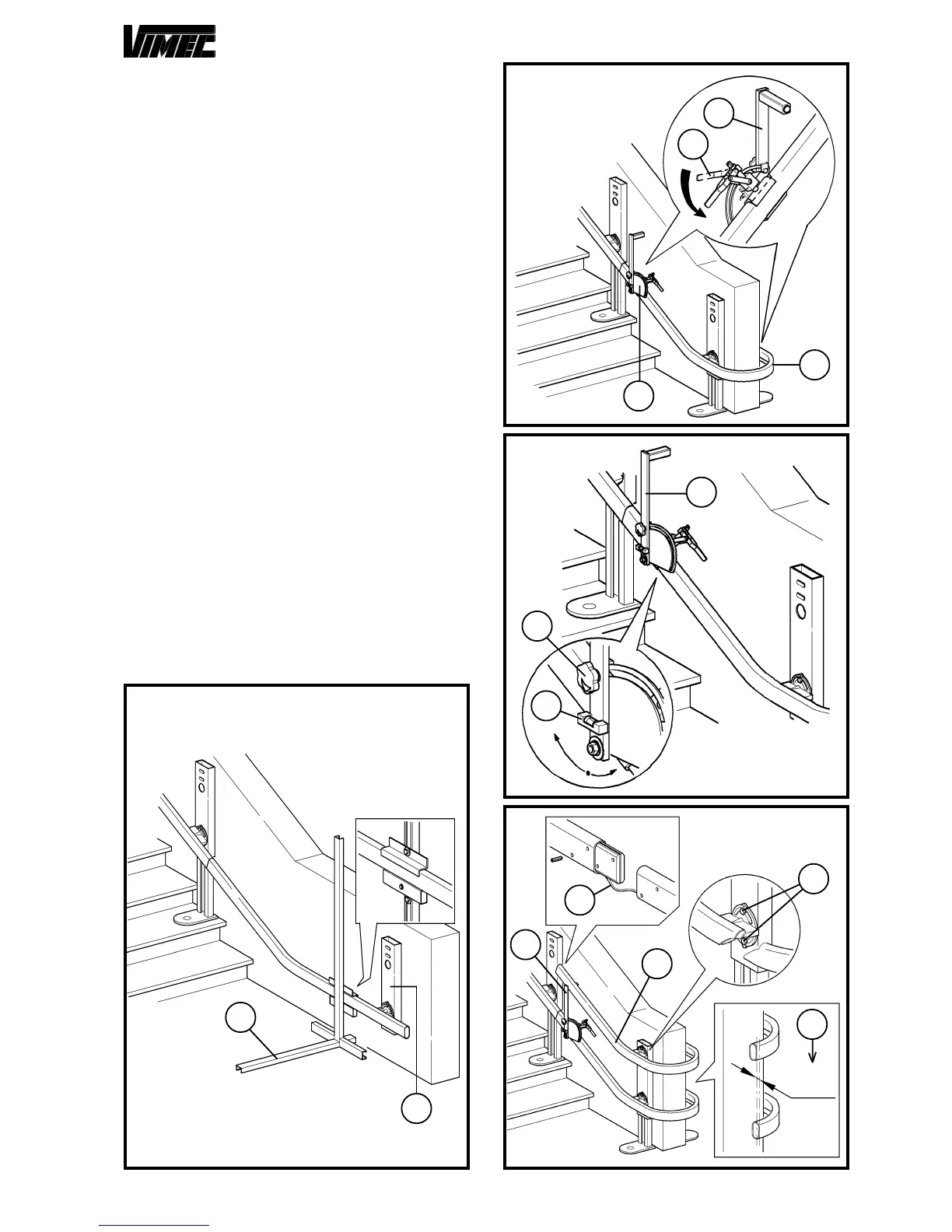

In order to facilitate the assembly operation for the wall

fastening (Fig. 10/a), it is advisable using the special

test feet (Fig. 10/b) (ask the Vimec service department,

as they are not supplied) to insert on the guide instead

of the middle fastenings (almost 1-2 every ramp).

NOTE: Before carrying out any machine handling test,

the connection (Fig. 10/a) must be fixed to the wall.

3) INSTALLING THE UPPER RAIL

- Position the spacing gauges (Fig. 11/a) (ask the Vimec

service department, as they are not supplied), on the

extreme edges of the first positioned guide section (Fig.

11/b) (curve) and block them hard rotating the lever as

shown in figure (Fig. 11/c).

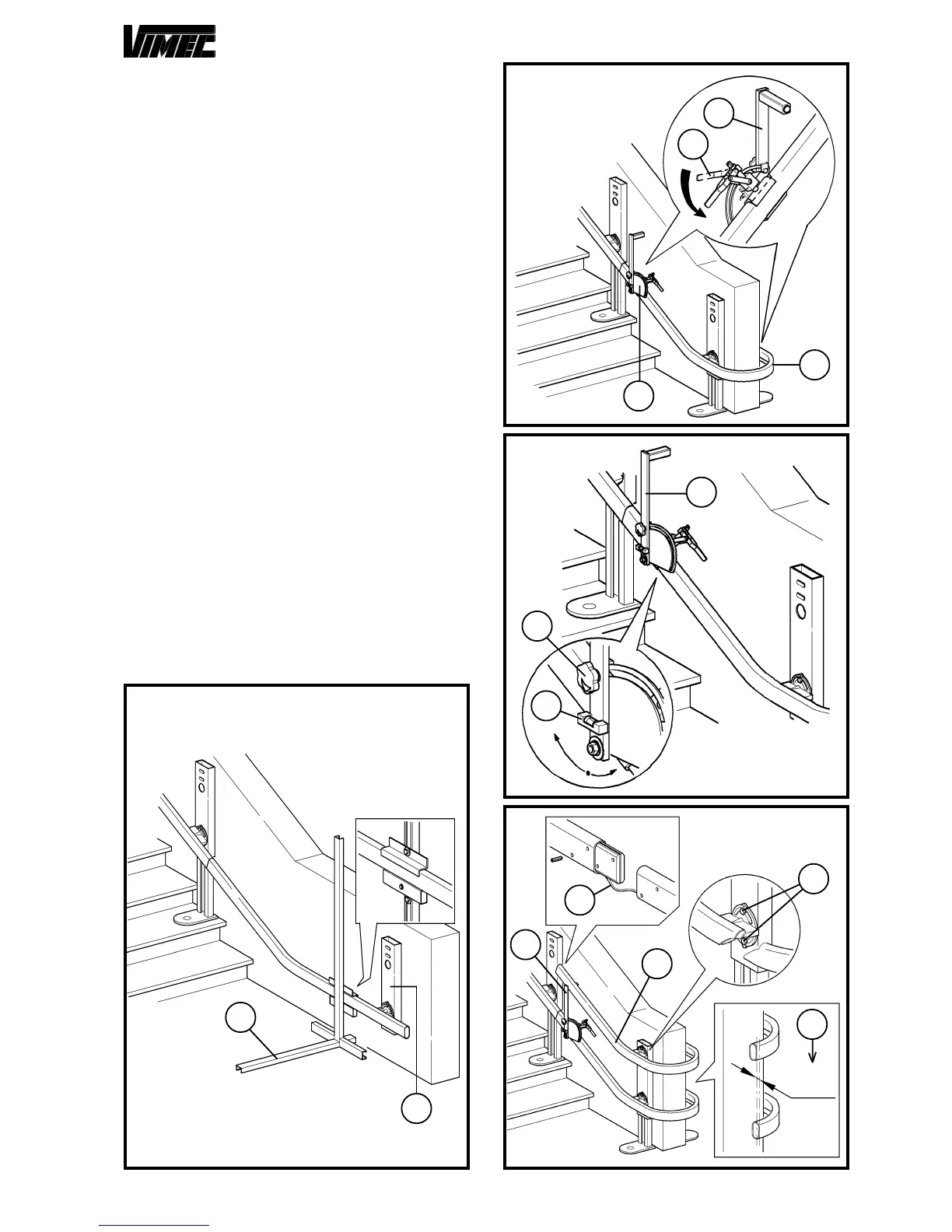

- By loosening the handwheel (Fig. 12/a) and using a

spirit level (Fig. 12/b), position the support arm (Fig.

12/c) in perfectly vertical position. Once the adjustment

has been done, tighten the handwheel hard (Fig. 12/a).

- Position the upper guide (Fig. 13/a) on the spacing

gauges (Fig. 13/b) formerly positioned, and after having

checked the correct vertical sense (Fig. 13/c),

tighten the screews (Fig. 13/d) hard.

CAUTION: The couple securing the guide fixing

screws (Fig. 13/d) must be 6-7 daNm.

- Carry out the assembly of all the guide sections remained,

proceeding in sequence as formerly described down to

the bottom of the scale except the last one. If included

in the kit, insert the cable for push-button panles (Fig.

12/e) during the guides connection.

- When finished the assembly, retouch guides with sup-

plied black paint and seal the screws (Fig. 9/g) and the

nuts (Fig. 9/h) of the busway junction.

FIG.10

FIG.11

FIG.13

FIG.12

a

c

a

b

c

a

b

b

a

0±1

mm

e

d

a

b

c

Loading...

Loading...