11

Installation

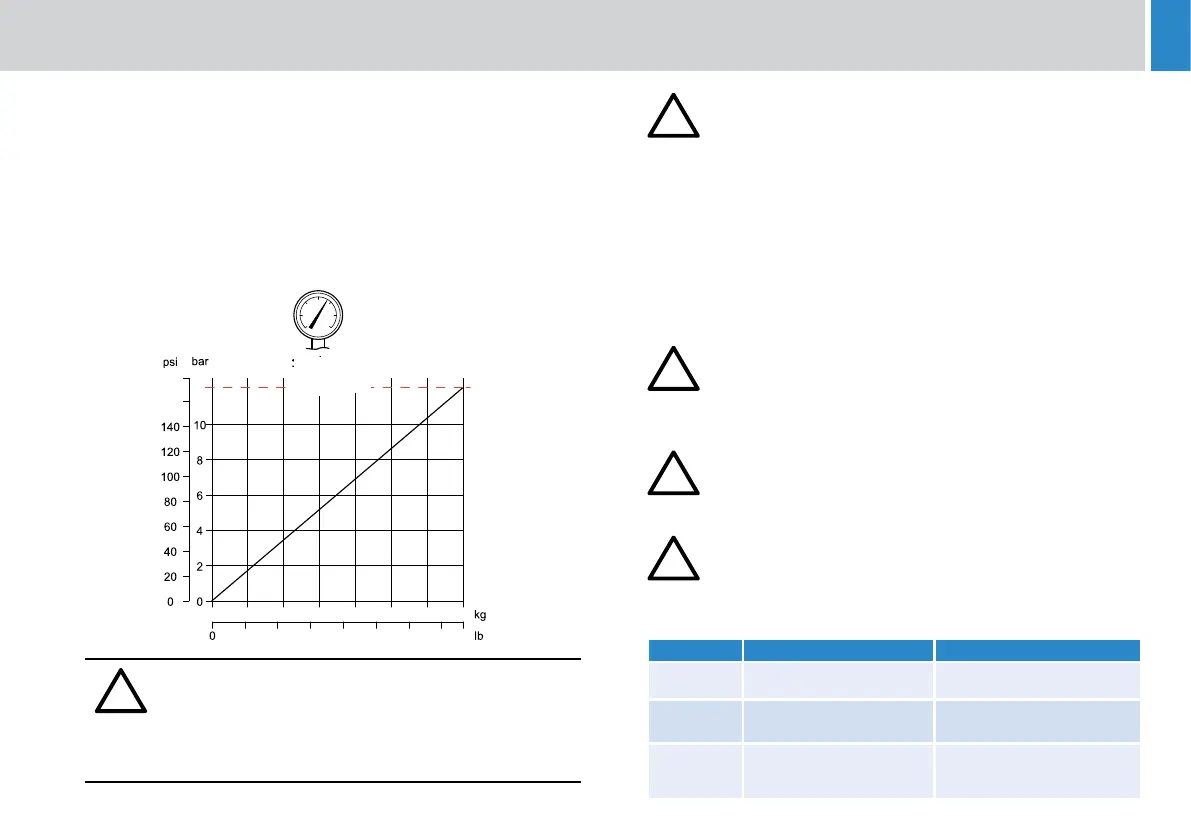

Pressurizing the pedestal

The pedestal may be pressurized using the built-in pump, by using a

Portable Pump or from an external pressure source.

Ascertain the payload to be tted to the pedestal (payload = pan and

tilt head, camera, lens and all ancillary equipment). Referring to the

graph below, mark the payload on the horizontal axis then strike a

vertical line from the load gure to the balance line. At the intersecting

point strike a horizontal line to the vertical axis and read o the

required gas pressure.

!

WARNING! Do not pressurize the pedestal beyond the

maximum safe working pressure indicated by the leading

edge of the red sector on the gauge. The pedestal is tted

with a pressure relief valve as a safeguard against over-

pressurization. Do not attempt to adjust the pressure relief

valve. Remove the payload before pumping.

!

WARNING! This pedestal must be pressurized only with

clean, dry air or nitrogen. A pressure reducing valve must

be tted to the pressure line between the cylinder and the

outlet connection of the hose. The reducing valve must

be screwed into the gas cylinder outlet. The maximum

pressure on the outlet side of the reducing valve must not

exceed 11.7 bar (170 psi). Do not pressurize the pedestal

beyond the maximum safe working pressure indicated

by the leading edge of the red sector on the gauge.

The pedestal is tted with a pressure relief valve as a

safeguard against over-pressurization.

Do not attempt to adjust the pressure relief valve.

!

WARNING! A pressurized pedestal will rise rapidly when

safety catch is released. Do not release safety catch

when pedestal is pressurized and balancing load is not

installed. Always restrain the pedestal by hand pressure

on the steering ring when the safety catch is released.

!

WARNING! Bottom stage elevation is assisted by a gas

strut. The bottom stage will rise rapidly if released with

no payload tted. Do not lean over the pedestal when

releasing the safety catch and/or the bottom clamp.

!

WARNING! A pressurized pedestal will rise rapidly if the

control valve is set to WORK.

Do not move the control valve directly from PUMP to

WORK.

11

160

11

12

180

160

100

20 40 60 80 100 120 140 155

20 30 40 50 60 70

≤ 11.7 bar

(170 psi)

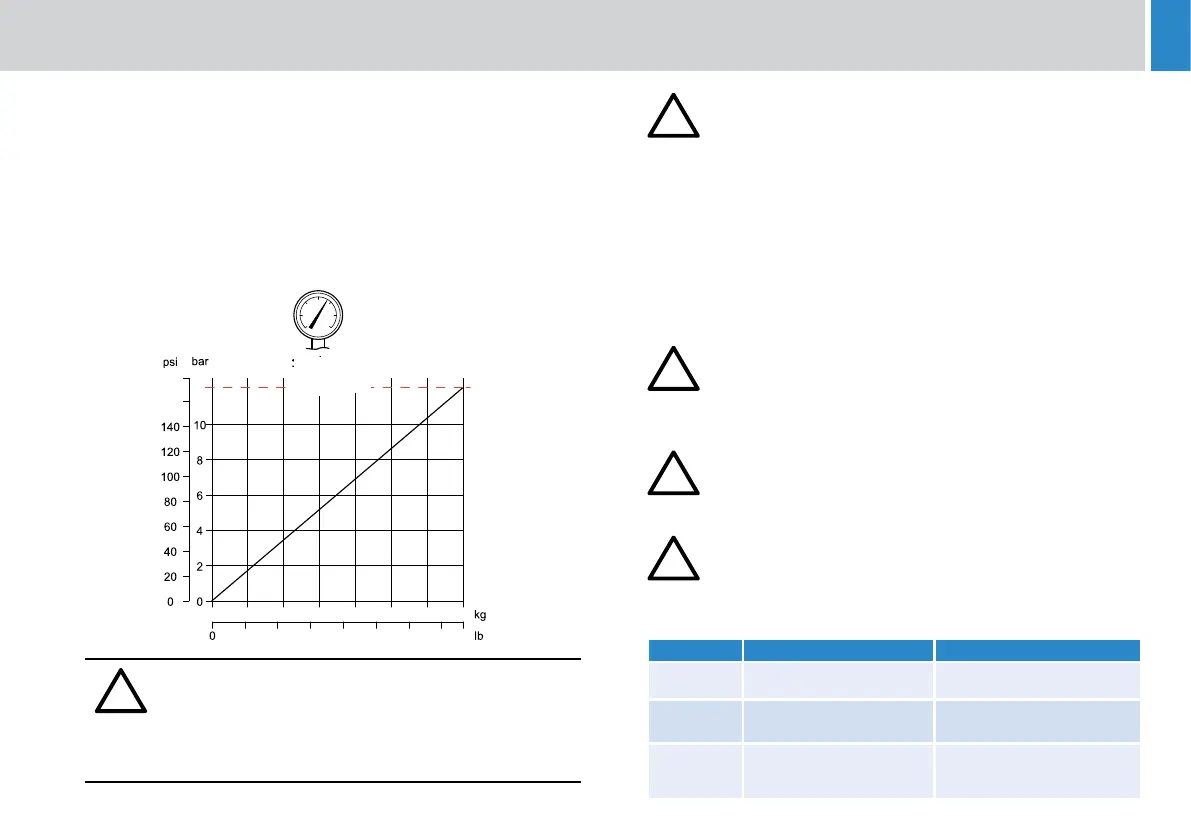

Method Advantages Disadvantages

Integrated Pump

(For units that have

this.)

• No accessory needed

• Less strokes than manual Pump

• Cannot pump with payload tted.

Gas Bottle

• Fast

• Can add gas with payload tted

• Not always available

• Recommended training needed for

working with compressed gas.

Manual Floor Pum

• Easy for topping up.

• Readily available

• Self pump not available for all peds.

• Physically demanding so not

recommended for payloads over 60kg.

• Some pumps cannot achieve max

pressure on some models.

Loading...

Loading...