R750EU5 - IE3 - TE4 - IE4 - ISE4

English 38 Ed.8 / 10-2012

GB

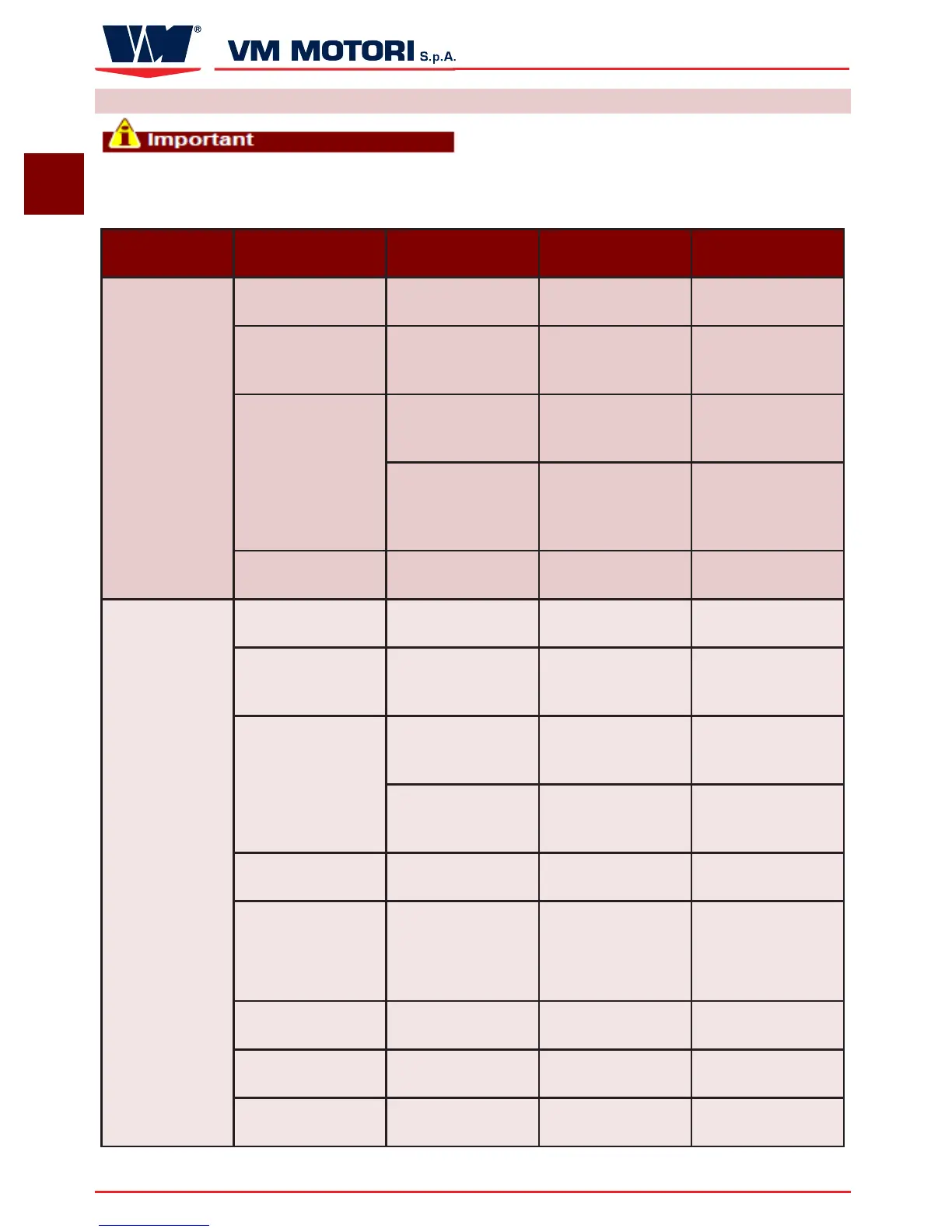

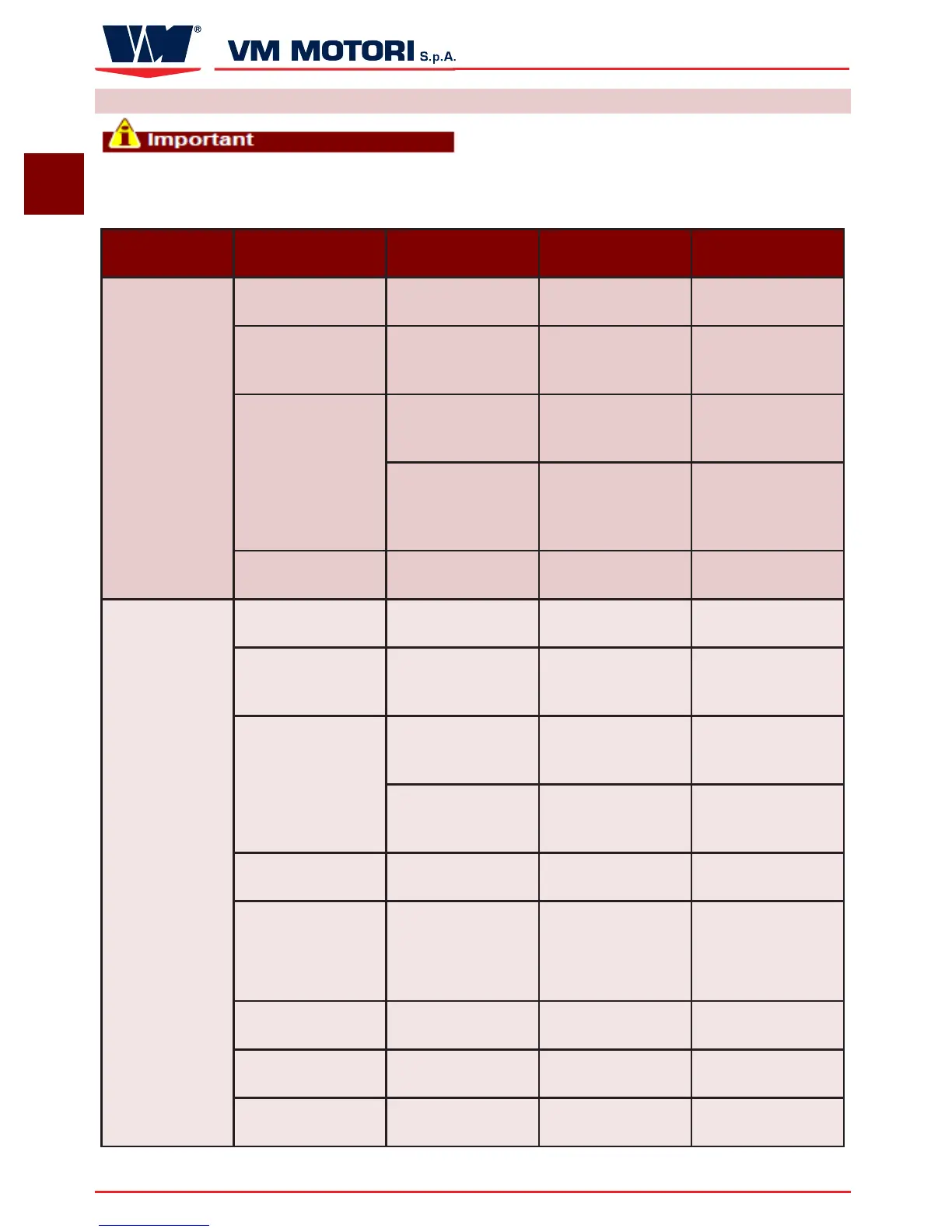

ROUTINE MAINTENANCE (AFTER RUNNING-IN)

Frequency

(1)

Component

Type of inter-

vention

Intervention

procedures

Reference

Every 10

hours

Engine oil (2) Level control

Top up, if nec-

essary

See “Engine oil

level control”

Coolant (4) Level control

Top up, if nec-

essary

See “Engine

coolant level

check”

Air lter

Check it is

clean

Clean with low

pressure com-

pressed air.

Check the clog-

ging indicator

that is installed

on the lter body

Clean the lter

or, if necessary,

replace it with a

new one.

See “Cleaning

and replacement

of the air lter”

Coolant uid

radiator

Check it is

clean

Clean with a

soft brush

Every 300

hours (6)

Engine oil (2)

(6)

Replace

See “Engine oil

change”

Oil lter

Replace the

cartridge

See “Oil lter

cartridge re-

placement”

Air lter

Replace the

main cartridge

See “Cleaning

and replacement

of the air lter”

Check if the

safety cartridge

is clean

Clean with low

pressure com-

pressed air.

See “Cleaning

and replacement

of the air lter”

Fuel lter Replace

See “Fuel lter

replacement.”

Air intake circuit

and intercooler

pipe

Check it is

clean

Check of pipe

sealing

Dust discharge

circuit

Check it is

clean

Oil separation

circuit

Check of pipe

sealing

Vacuum circuit

Check of pipe

sealing

For each maintenance operation, ll in the

“Periodic maintenance operation record sheet” provided, so as to keep a trace of

the operations performed and therefore establish the most suitable methods for

future operations.

Loading...

Loading...