R750EU5 - IE3 - TE4 - IE4 - ISE4

English 47 Ed.8 / 10-2012

GB

CHECKS AND CONTROLS

CONTROL SCREW TIGHTENING AND UNION SEALING

FUEL SUPPLY CIRCUIT BLEEDING

Pump (F)

Bleed

screew

(E)

The list indicates some of the maintenan-

ce, testing and control operations to be

carried out on the engine during normal

operation.

– Fuel supply circuit bleeding

–Control screw tightening and union

sealing

–Engine oil level control

–Engine coolant level check

–Procedure for loosening or tensioning

the belt

–Engine oil change

Follow the procedure below.

1- Start the engine and run it at minimum

speed for a few minutes.

2-Run the engine at normal speed until

the operating temperature (70÷80°C) is

reached.

3- Turn off the engine and let it cool down.

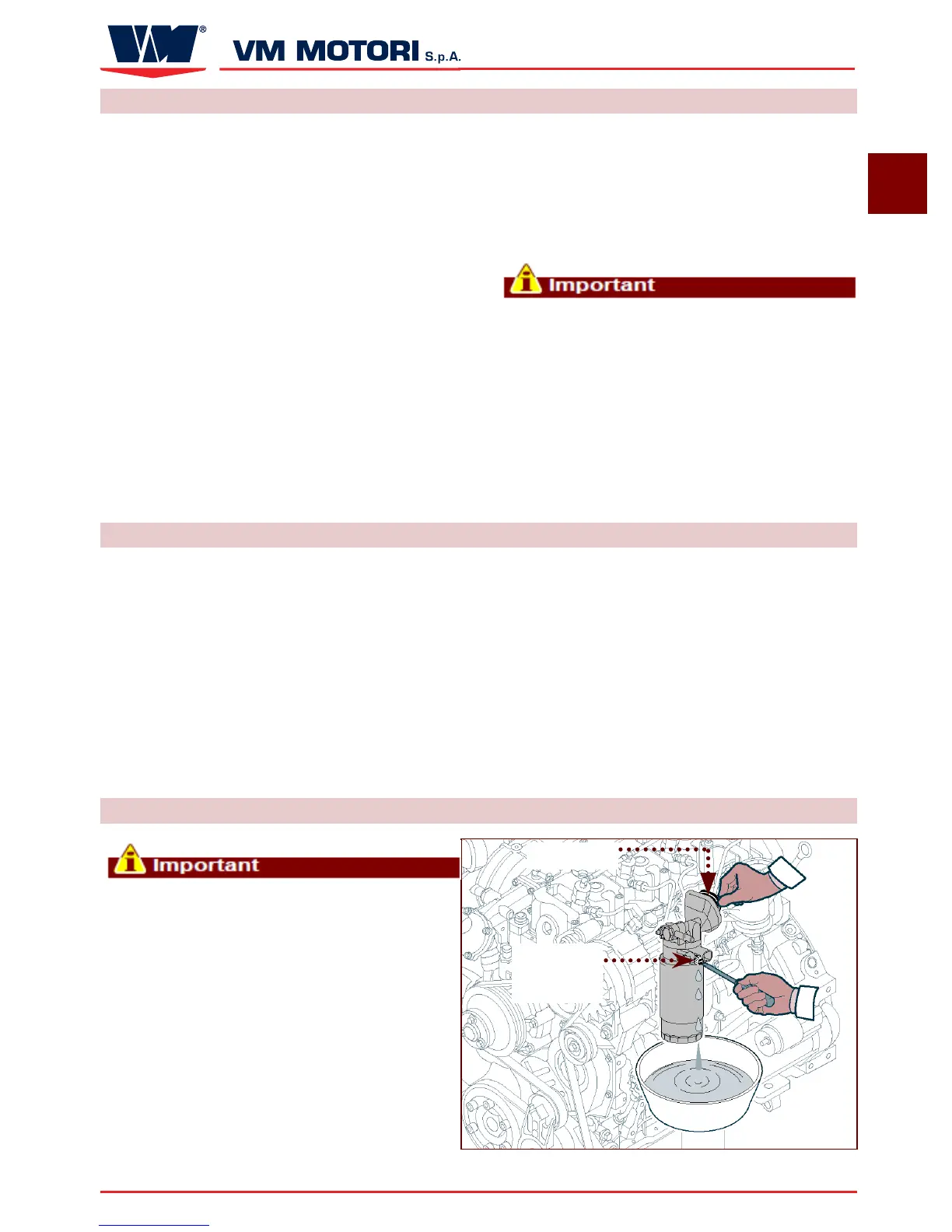

This operation must be carried out

each time the fuel cartridge is changed

Follow the procedure below.

1- Turn off the engine and remove the

ignition key.

2- Let the engine cool down adequately to

avoid being burnt.

–Coolant replacement

–Oil lter cartridge replacement

– Fuel lter replacement.

– Cleaning the antiparticulate lter

For each maintenance operation, ll in

the “Periodic maintenance operation

record sheet” provided, so as to keep a

trace of the operations performed and

therefore establish the most suitable

methods for future operations.

4-Make sure the xing screws of the main

parts are tightened properly.

5- Check the union sealing on the fuel

supply circuit.

6- Check the tightening of the clamps.

7- Check any uid leaks.

Loading...

Loading...