Engine body

Fitting of cylinder head

1.

Clean the surface of the cylinder head and cylinder

block. Remove any rust or soot from the screw ho-

l

es and threads for the cylinder head screws.

2.

Fit on the new cylinder head gasket.

3.

Apply grease containing molybdenum disulphide

on the cylinder head screws.

NOTE! The screws are surface treated and must

not be cleaned with a steel brush.

Note:

I

f the cylinder head is painted the mating sur-

faces for cylinder head screws must be free from

paint, otherwise the clamping force in the screw

union will be adversely affected.

4.

Check that the tubular pins (guides) are fitted in the

block. Place the two rear cylinder head screws in

the cylinder head and fit the head.

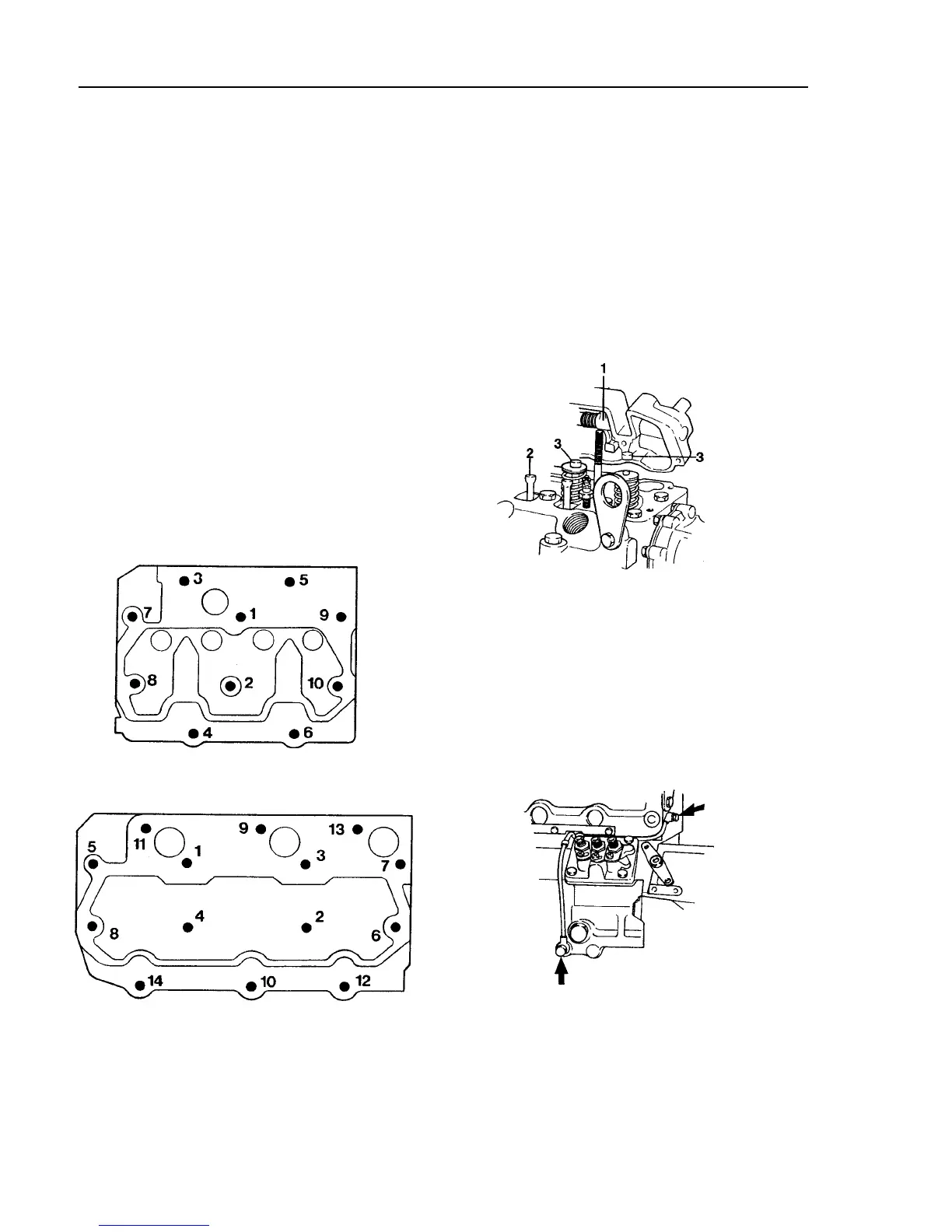

Fig. 30. Tightening diagram, MD2O10

Fig. 31. Tightening diagram MD2020, MD2030, MD2040

1st tightening

MD2O10. MD2020

10 Nm (7.40 ft.lbs)

MD2030

20 Nm (14.80 ft.lbs)

MD2040

30 Nm (22.10 ft.lbs

2nd tightening

MD2O10, MD2020

20 Nm (14.80 ft.lbs)

MD2030

35 Nm (25.80 ft.lbs)

MD2040

70 Nm (51.70 ft.lbs)

Final tightening

MD2O10, MD2020

35-40 Nm (26-30 ft.lbs)

MD2030

50-53 Nm (37-39 ft.lbs)

MD2040

90-95 Nm (66-70 ft.lbs)

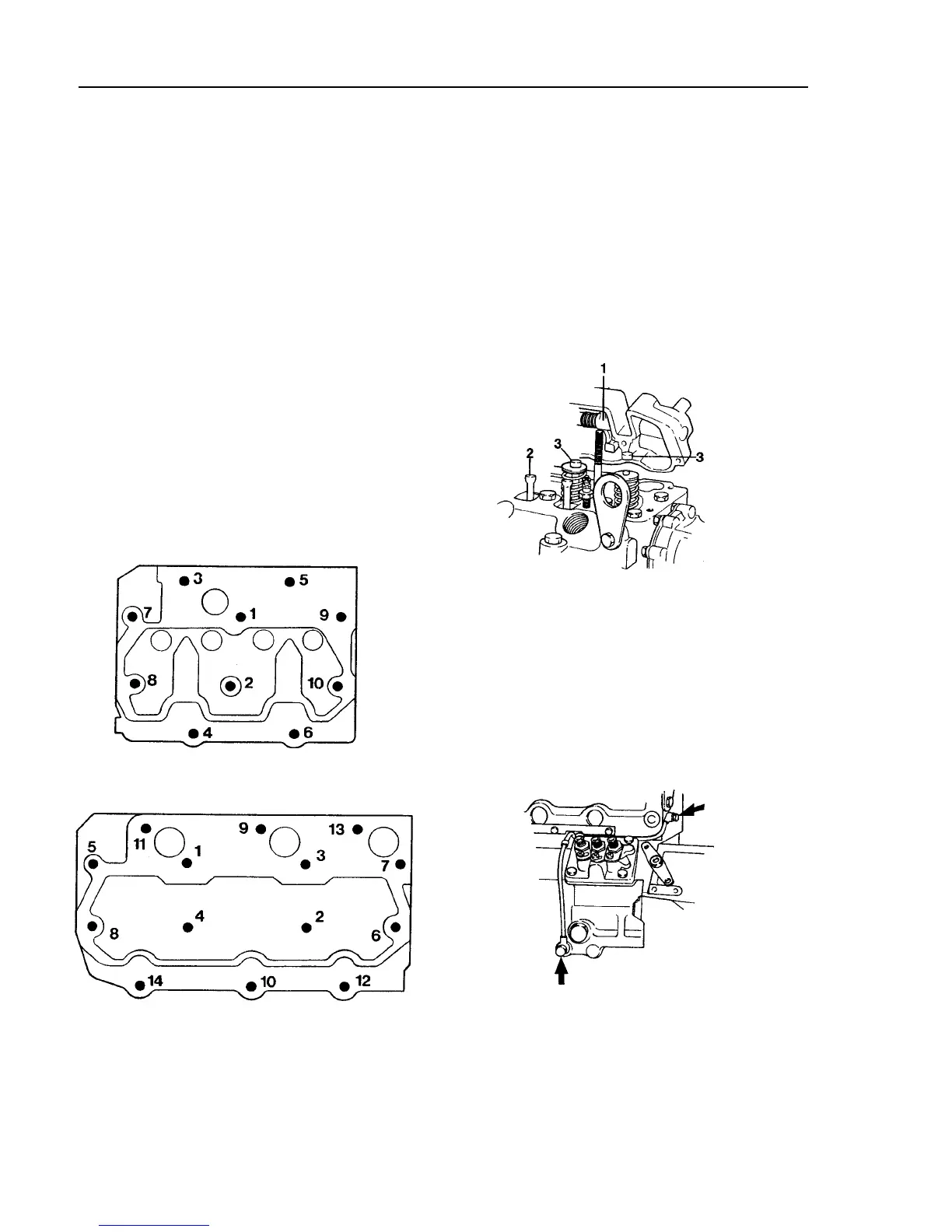

Fig. 32. Fitting of the rocker mechanism (MD2040)

6.

Fit the pull rods (2), valve caps (3, MD2040 and

l

ater versions of 2010, 2020,2030) and rocker

mechanism (1).

7.

Adjust the valve clearance as per directions on

page 34. Fit the valve cover.

Fig. 33. Fitting of oil pressure pipe (cylinder block -

cylinder head / rocker mechanism)

e

8.

Fit the oil pressure pipe between the block and

5.

Tighten the cylinder head screws in three stages as

cylinder head (rocker mechanism on MD2040).

per the following. See tightening diagrams Fig. 30-

31.

Tightening torque 10-13 Nm (7.4-9.6 ft.lbs).

32

Loading...

Loading...