Fuel system

Repair instructions

Observe the greatest possible cleanliness when work-

i

ng with the fuel system.

I

njection pump

Dismantling of the injection pump

NOTE! Repair work on the injection pump which

may change its setting should only be carried out

by specially trained mechanics which have the

requisite equipment at their disposal.

Engine warranties are not longer valid if the seals

are broken by unauthorised personnel.

1.

Carefully wash clean the injection pump, pipes and

the engine around the pump.

2.

Close the fuel cocks. Remove the delivery pipe

complete. Release the fuel hose from the pump.

Fit protective caps on all connections.

5 4

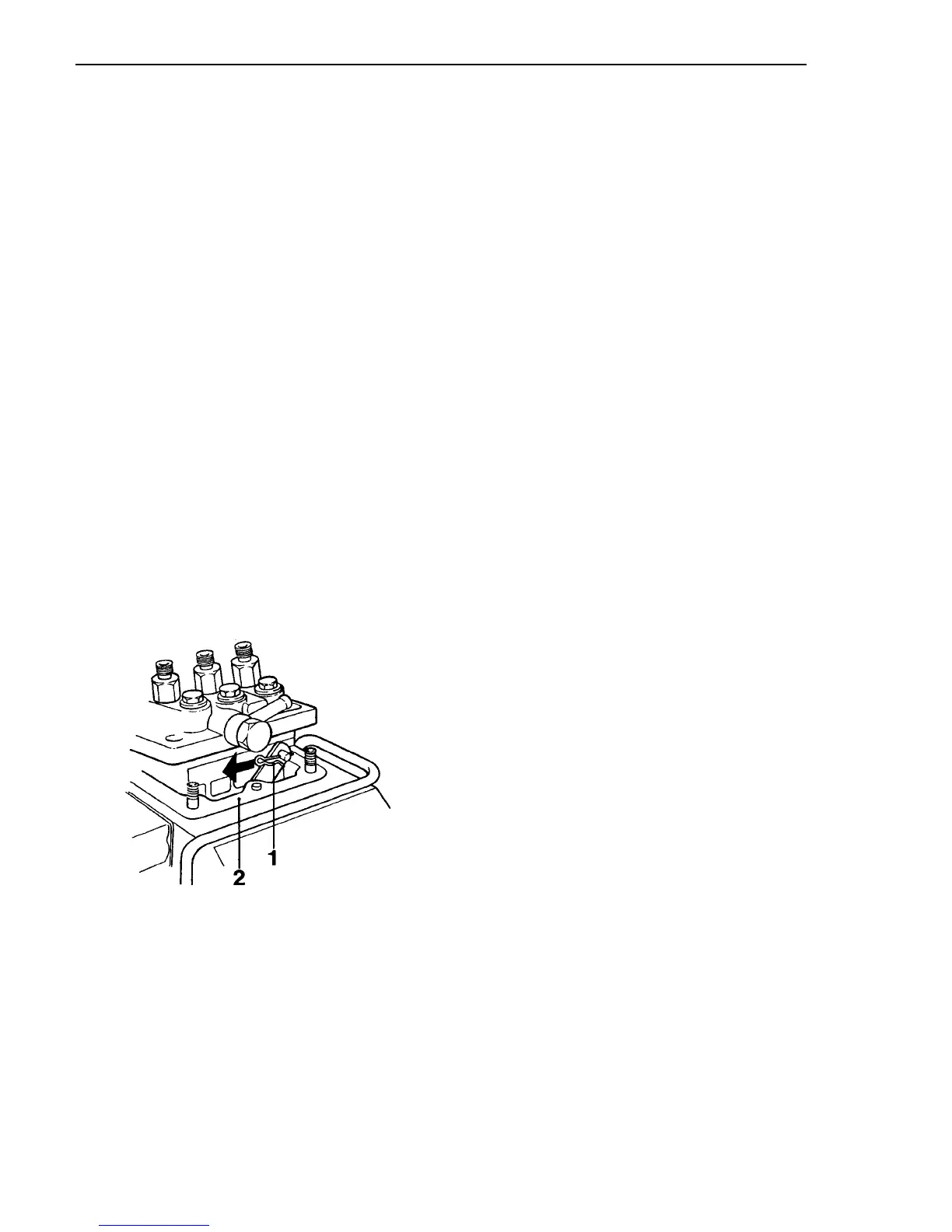

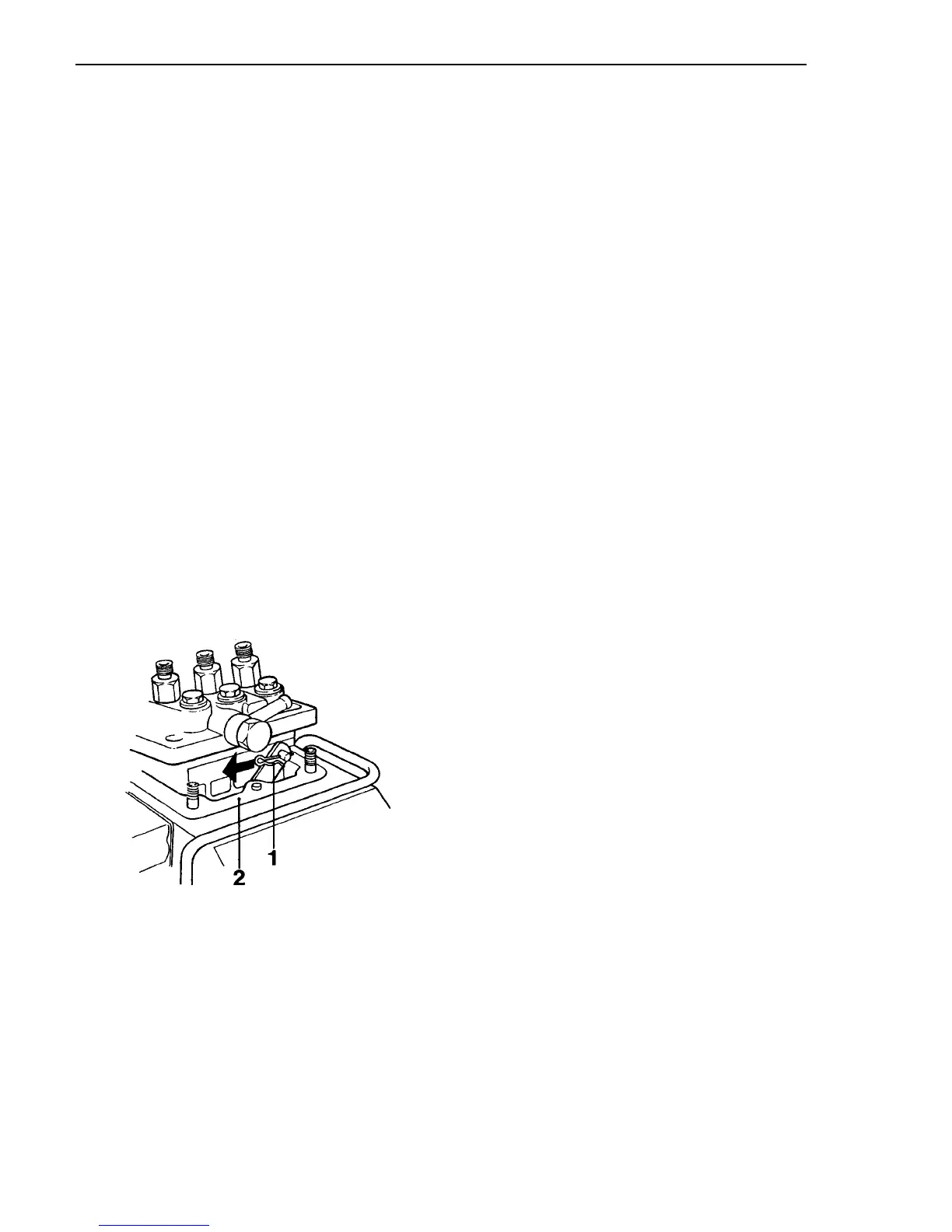

Fig. 87. Dismantling of the injection pump

1.

Lock pin

2.

Shims

3.

Dismantle the pump's attachment screws and nuts.

Turn the stop lever clockwise and carefully lift up

the pump so that the lock pin to the regulator arm

becomes accessible (Fig. 87).

Remove the lock pin and release the regulator arm.

NOTE! Take care of the shims under the injec-

tion pump flange when the pump is lifted off the

cylinder block.

4.

Send the pump to an authorised diesel workshop*

for inspection if the workshop does not have spe-

cially trained personnel with the necessary testing

equipment.

'MD2o10, MD2020, MD2030: Nippondenso.

MD2040: Bosch.

Fitting of the injection pump

Check that the pump is in good condition, and if so re-

quired also tested and approved before it is fitted.

Note:

Do not remove the protective caps before the

pipes are connected.

1.

Put the injection pump in the cylinder block.

NOTE! Make sure that the shims which were

placed under the injection pump flange are put

back in place before the pump is'put in the

block.

Note:

The correct pump setting is normally ob-

tained with this method. If the injection pump, cam-

shaft or cylinder block have been replaced the set-

ting of the pump must be adjusted. See next

section, "Adjustment of injection angle":

2.

Turn the stop lever clockwise and connect the

regulator arm to the control rod on the pump. Fit the

l

ock pin (Fig. 87). Screw tight the pump.

3.

Connect the fuel hose and fuel leak pipe to the

pump. Fit the delivery pipe.

4.

Bleed the fuel system and test run the engine.

Loading...

Loading...