Fitting and adjustment

Q

WARNING!

I

f the crankshaft and camshaft are

turned without being synchronised with each

other the valves can go against the pistons and

be damaged.

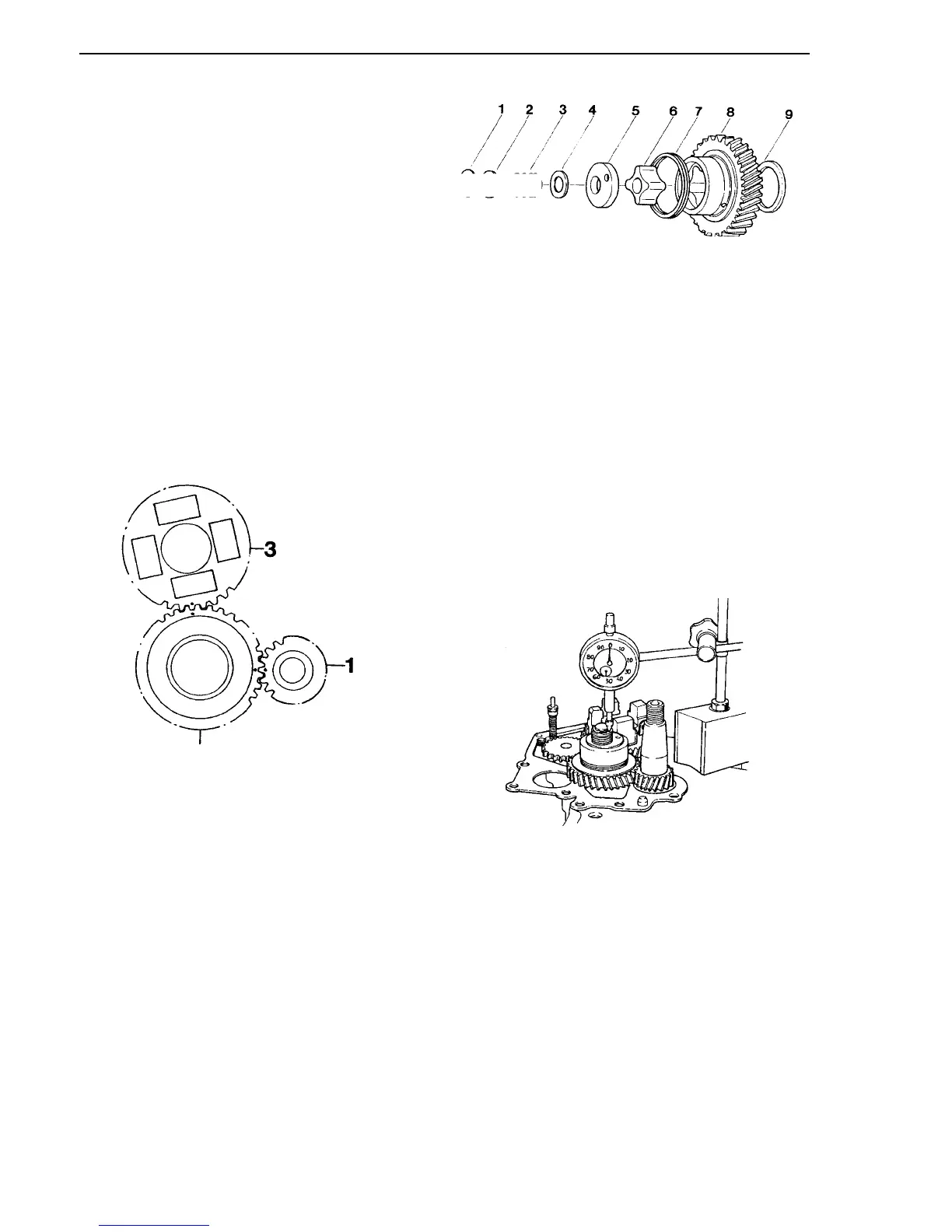

Note: The gears in the timing gears which are of import-

ance for adjustment are marked as follows:

Crankshaft gear - the intermediate gear is marked with

a punch mark and the intermediate gear - camshaft

gear with a circle opposite the tooth and tooth gap

(Fig. 61).

1.

Put the key in position in the crankshaft and fit the

crankshaft gear.

2.

Fit the camshaft complete with regulator weights.

Carry out work steps to item 4 under the heading

"Fitting of camshaft" on page 45.

4 2

Engine body

2

Fig. 61. Timing gears, basic setting

1.

Crankshaft gear

3.

Camshaft gear

2.

I

ntermediate gear

3.

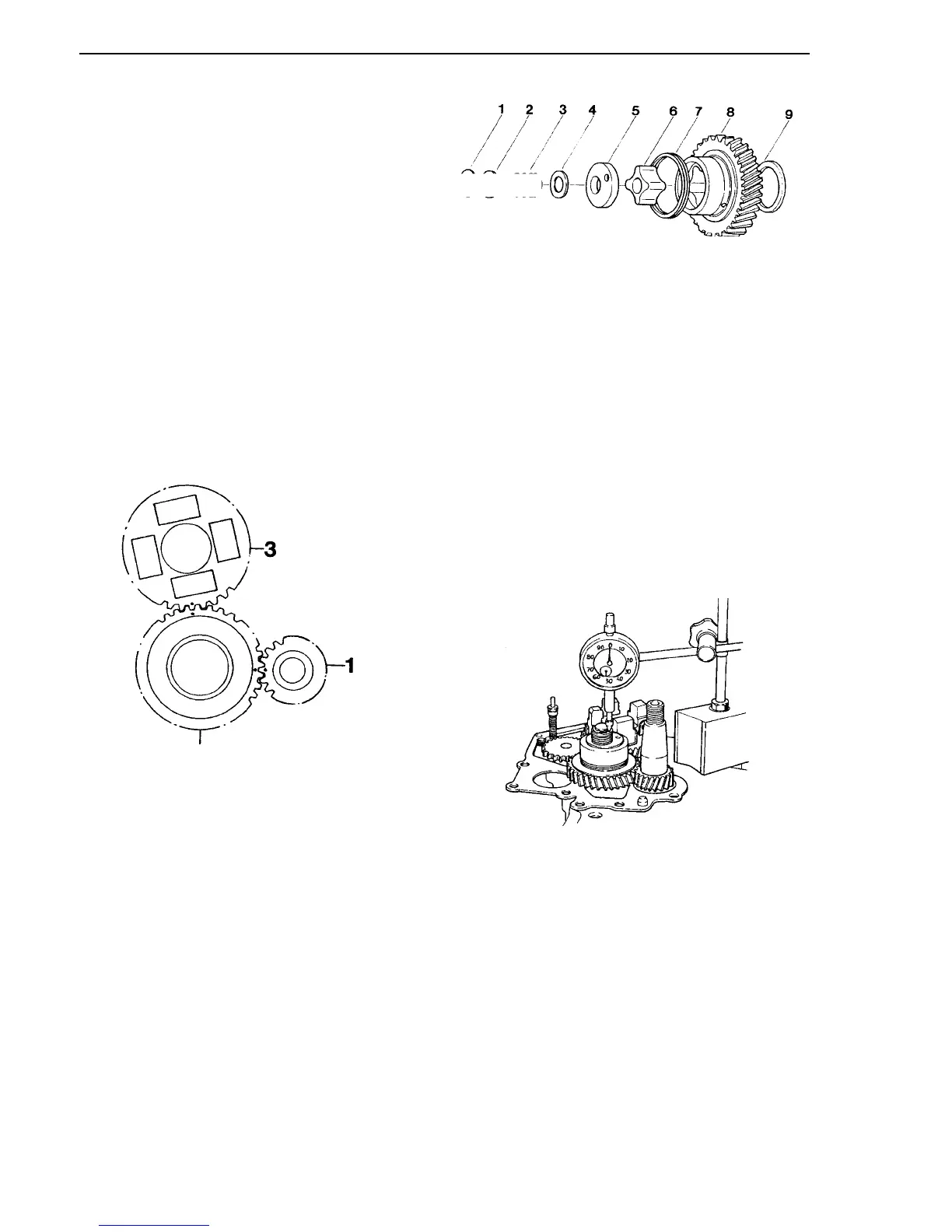

Fit the thrust washer (9, Fig. 62) on the intermedi-

ate gear's shaft journal. Fit the intermediate gear as

per the markings (Fig. 61).

NOTE! Do not turn the crankshaft before the

ti

ming gear casing is fitted.

319

4.

Fig. 62. Intermediate gear complete with oil pump

1.

Circlip

7.

Spring

2.

Spring washer

8.

I

ntermediate gear

3.

Spring

complete with outer

4.

Shims

rotor

5.

Cover to oil pump

9.

Thrust washer

6.

I

nner rotor

Grease in the oil pump's inner rotor (6, Fig 62) and

housing (outer rotor, 8).

Fit the inner rotor and cover to the oil pump. Fit the

shims, spring, spring washer and lock washer as

per Fig. 62.

Fig. 63. Checking of oil pump's axial clearance

5.

Adjust the oil pump's axial clearance to 0.10-0.15

mm (.0039-.0059 in). Shims are available in sizes

0.10; 0.15; 0.20 and 0.50 mm (.0039, .0059, .0078

and.0196 in)

6.

Check the crankshaft seal in the timing gear cas-

i

ng, and replace if necessary. See under heading

"Replacement of front crankshaft seal" on page 40.

Loading...

Loading...