25

6.3 Testing the sensor positions

Inthecaseofliftingandtippingmechanismsforwhichtherearenoempiricalvaluesregardingthepositioningofthe

ultrasonicsensors,potentialsensorpositionsshouldbetestedwhereverpossiblebeforepermanentlyinstallingthem.

Sincesomespecialsituationsoffernosuitableinstallationpositionswhatsoever,incaseofdoubtthesetestsshouldbe

carriedoutasearlyaspossible,especiallybeforeinstallingcomponentsfortheautonomousbrakingsystem.

Thebestwaytotesttheinstallationpositionsisasfollows:

Theultrasonicsensorsaretemporarilyfastenedinplaceattheintendedinstallationlocationswithvelcrofasteners

oradhesivetape,orusingsuitableclamps.

TheElectronicExtensionModuleisalsoonlyinstalledtemporarily.

TheultrasonicsensorsareconnecteddirectlytotheECUwithoutthenalcablerouting

TheECUissuppliedwithpowerviathepowercable.

ThediagnosticsocketisconnectedtotheECU.

Themulti-corecablewhichcarriesthesignalindicatingthatreversegearhasbeenengagedisconnectedasusual

totheGIO12slotontheECU.Theotherend,however,isnotyetconnectedtothereversinglamp.Allthatis

requiredistoconnectthewirewiththepinkinsulationtoa24Vpowersupplytodeliverthesignalfortheengaged

reversegeartotheECU.

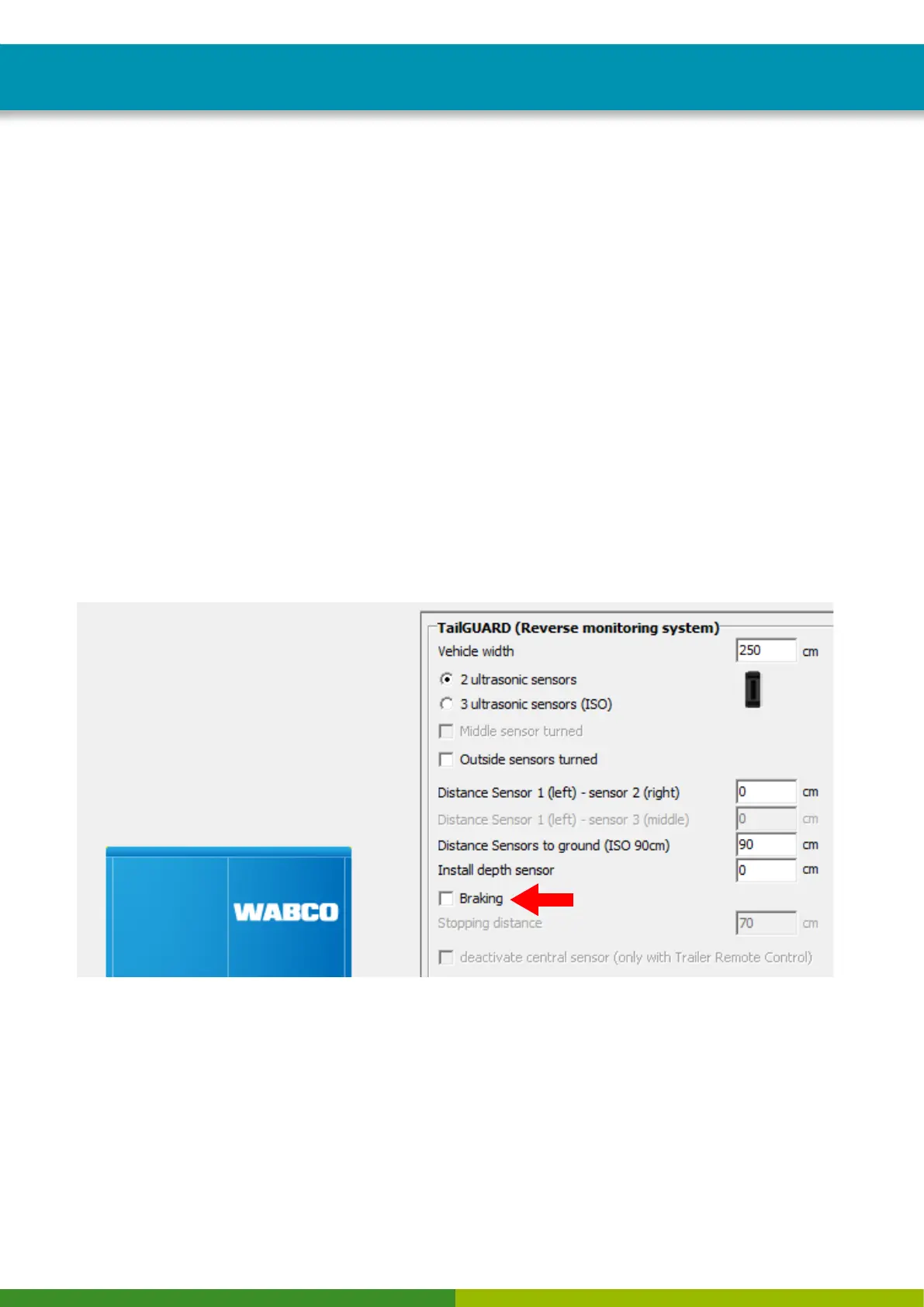

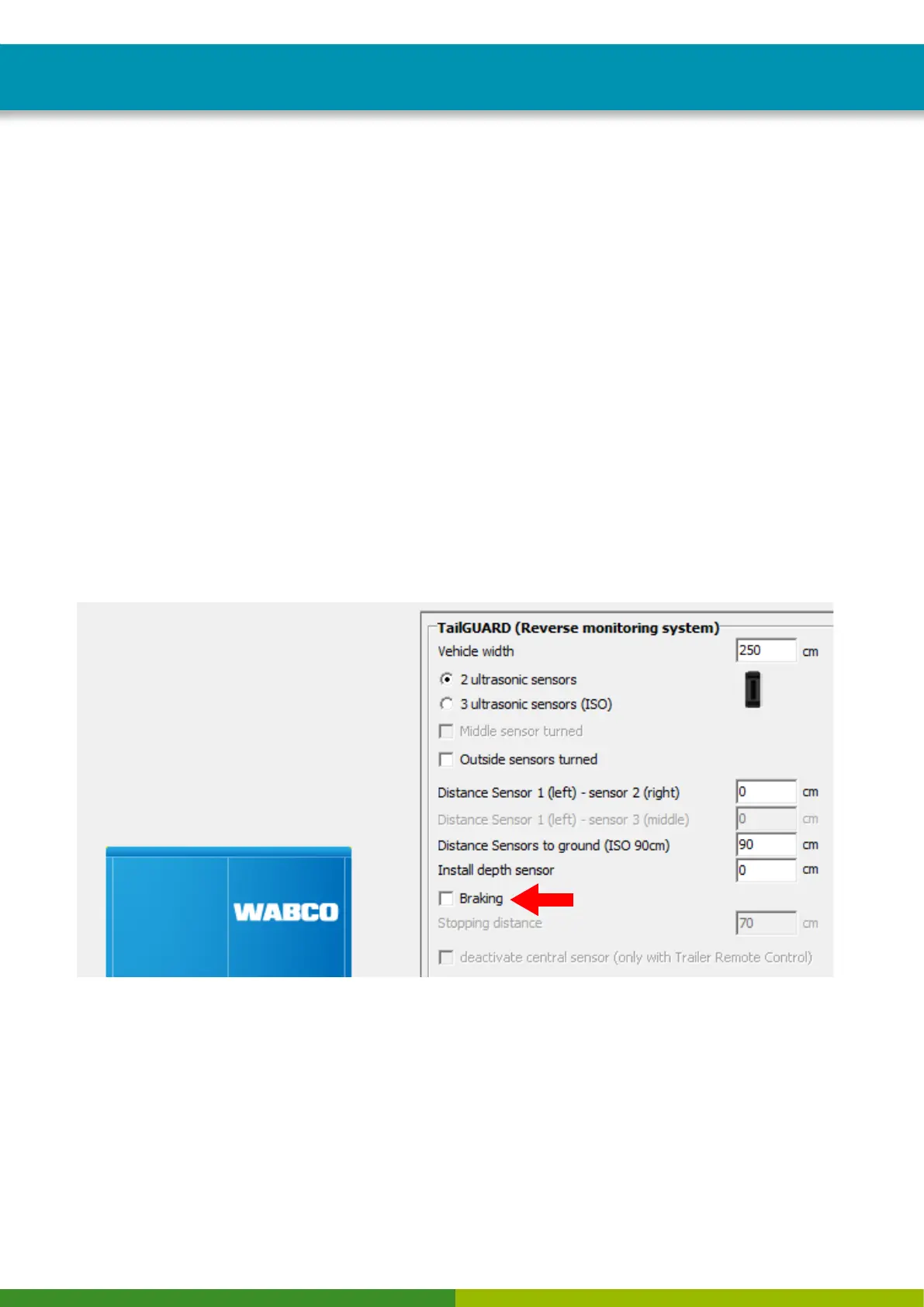

ThesystemcannowbestartedupwiththeaidoftheTEBSEDiagnosticSoftware.The"Braking"optionmustbe

deactivated:

Afterthesystemhassuccessfullystartedup,itattemptstoteachtheconnectedultrasonicsensorsattheiractual

installationpositions.Ifthisfailsbecausereectionsarebeingpermanentlydetected,therelevantinstallation

positionshavetobeoptimisedordifferentoneshavetobefound.

Installation of the ultrasonic sensors

Loading...

Loading...