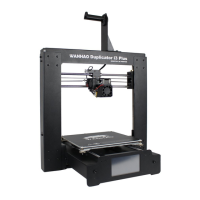

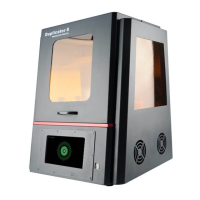

This document is a user manual for the GADOSO Revolution 2 (GR2) 3D printer, also referred to as a WANHAO 3D Printer. It covers initial setup, technical specifications, software usage, and maintenance.

Function Description:

The GADOSO Revolution 2 (GR2) is a 3D printer designed for creating three-dimensional objects using Fused Filament Fabrication (FFF) technology. It operates by laying down material, such as PLA or ABS filament, in successive layers to build a 3D object. The printer is capable of remote operation via a mobile application.

Important Technical Specifications:

- Software: WANHAO Cura

- Extruder System: MK10

- Material Support: ABS, PLA

- Max Printable Area: 200 * 200 * 175 mm

- Filament Diameter: 1.75MM

- Max Printing Speed: 30 mm/s - 100 mm/s

- Case Material: Steel case

- Extruder Quantity: 1

- Net Weight: 13kg

- Gross Weight: 14.8kg

- Accuracy: X:0.05 mm, Y:0.05 mm, Z:0.05mm

- Packing Size: 46CM x 44CM x 55.5cm

- Layer Thickness: 100-400 um

- Platform: Aluminium platform with heating

- Certification: CE, CB, FCC

- LCD Display Size: 75*51 mm

- Language Support: Chinese, English, Netherlands, French, German, Italian, Spanish

- Power Supply Unit: Input 110 AND 250V (optional), 50/60Hz, 350W, 1.9A. Output 24V 4.5A

Usage Features:

The GR2 printer is designed for ease of use, with features supporting both local and remote operation.

- Initial Setup: The manual guides users through connecting to Wi-Fi, selecting a language (from 7 options including English, Chinese, French, German, Italian, Spanish, and Dutch), and updating firmware.

- Mobile App Remote Operation: The printer integrates with the "WANHAO PlaySmart APP" for mobile phone control. This app allows users to download and manage print jobs, monitor printing status, and access a library of sliced 3D models for convenient printing. The app requires pairing with the printer via QR code or manual serial number input.

- Interface: The printer features an LCD screen with a user-friendly interface. Key elements include:

- New Print option for file selection (SD card or USB).

- Display of print time and completion rate.

- Camera and Settings options.

- Temperature displays for extruder and print bed, with target settings.

- Adjustment keys for data and temperature.

- Filament load/unload functions.

- Real-time print interface showing temperature, hot bed temperature, and fan speed.

- Filament Management: The manual provides instructions for installing and removing filament, emphasizing the importance of proper spool positioning and counter-clockwise direction. It also details the "Load" and "Unload" functions, which involve heating the thermal head and feeding/retracting filament.

- Cura Software Integration: The printer uses WANHAO Cura, a free Open Source slicer software, for preparing 3D models for printing.

- Loading 3D Designs: Users can load .STL, .OBJ, .DAE, or .AMF files onto the platform. The software automatically arranges multiple objects.

- Viewing and Positioning: Cura allows users to zoom, rotate, and pan the 3D model, as well as move its position on the build plate.

- Print Settings (Quick Print Mode): Offers profiles for High Quality, Medium Quality, and Fast Quality prints, adjusting layer height and print speeds. Users can select material (PLA, ABS, U-PET) and enable print support structure.

- Advanced Print Settings: Provides granular control over various parameters:

- Quality: Layer height, shell thickness, enable retraction.

- Fill: Bottom/top thickness, fill density.

- Speed and Temperature: Print speed, printing temperature, bed temperature.

- Support: Support type (Touching Buildplate, Everywhere), overhang angle, fill amount, distance X/Y, distance Z.

- Platform Adhesion: Brim (single layer around model to increase surface area), Raft (layer underneath object for adhesion).

- Filament: Diameter (critical for accurate filament calculation), flow percentage.

- Machine: Nozzle size (0.4mm).

- Retraction: Speed and distance to prevent dripping during travel moves.

- Quality (Initial Layer): Initial layer thickness and line width for bed adhesion.

- Speed (Layer Specific): Travel speed, bottom layer speed, infill speed, outer shell speed, inner shell speed.

- Cool: Minimal layer time, enable cooling fan (with settings for full height, min/max speed).

- Black Magic: Options to spiralize outer contour or only follow mesh surface for specific aesthetic effects.

- Fix Horrible: Advanced options to repair mesh errors in models.

- Plugins: Supports custom settings like "Tweak at Z" (for changes at specific Z heights) and "Pause at Height" (for pausing prints, e.g., to switch filament colors).

- Start/End Gcode: Allows for custom Gcode commands to alter print behavior.

Maintenance Features:

- Warranty: The WANHAO GR1 (likely a typo, should be GR2) printer has a 12-month warranty on functionality of individual parts. Wear and tear components (exposure display, FEP foil) are excluded, with specific hour/cycle limits for these parts.

- Troubleshooting & Support:

- Users are advised to contact support via email (support@wanhao3dprinter.com, hello@wanhao3dprinter.com, sales@wanhao3dprinter.com) or phone (+86-571-6337-9578) for issues.

- A Google Forum is available for online support.

- The manual provides a "WARRANTY NOTICE" urging users to contact support before returning items.

- Safety Information: Emphasizes careful reading of the manual, following warnings, and observing guidelines for power connection/disconnection.

- General Safety: Operate on a stable surface, avoid outdoor use, prevent liquids from entering the chassis, use mild detergent for cleaning, disconnect from AC for storage.

- Electrical Safety: Input 110/240V AC, 50/60Hz, operational voltage 24V. Do not allow objects to rest on the power cord. Use supplied power cord set or UL/CSA certified replacement.

- Malfunction: Disconnect immediately and refer repairs to qualified service personnel.

- Resin Handling: Keep printer and resins out of reach of children. Resin is an irritant; wear gloves and use in a well-ventilated room. Avoid breathing fumes.

- Moving Parts: Caution against reaching inside the printer during operation and allowing time to cool down.

- Scraper Use: Be careful when using the scraper, do not direct it towards fingers.

- Environmental Conditions: Operate between 15°C and 30°C, and 20% to 50% humidity.

- Eye Protection: Recommended during cleaning or sanding printed models.

- Print Bed Calibration (Z-Axis Compensation): Instructions are provided for fine-tuning the print bed level, including:

- Waiting for the nozzle to cool.

- Removing residual filament.

- Adjusting bed height using arrow keys until slight resistance is felt with a paper inserted between the nozzle and print bed.

- Bed Levelling: A detailed process for levelling the print bed, involving unscrewing fastening nuts, moving the print head to different points, and adjusting the distance between the nozzle and platform using a levelling card.

- Filament Storage: Both PLA and ABS filaments are sensitive to moisture. Store in sealed, airtight bags/containers with silica gel to prevent quality deterioration.

- Disposal Instructions: Electronic devices should not be thrown into waste; recycle or return to Photocentric for recycling.