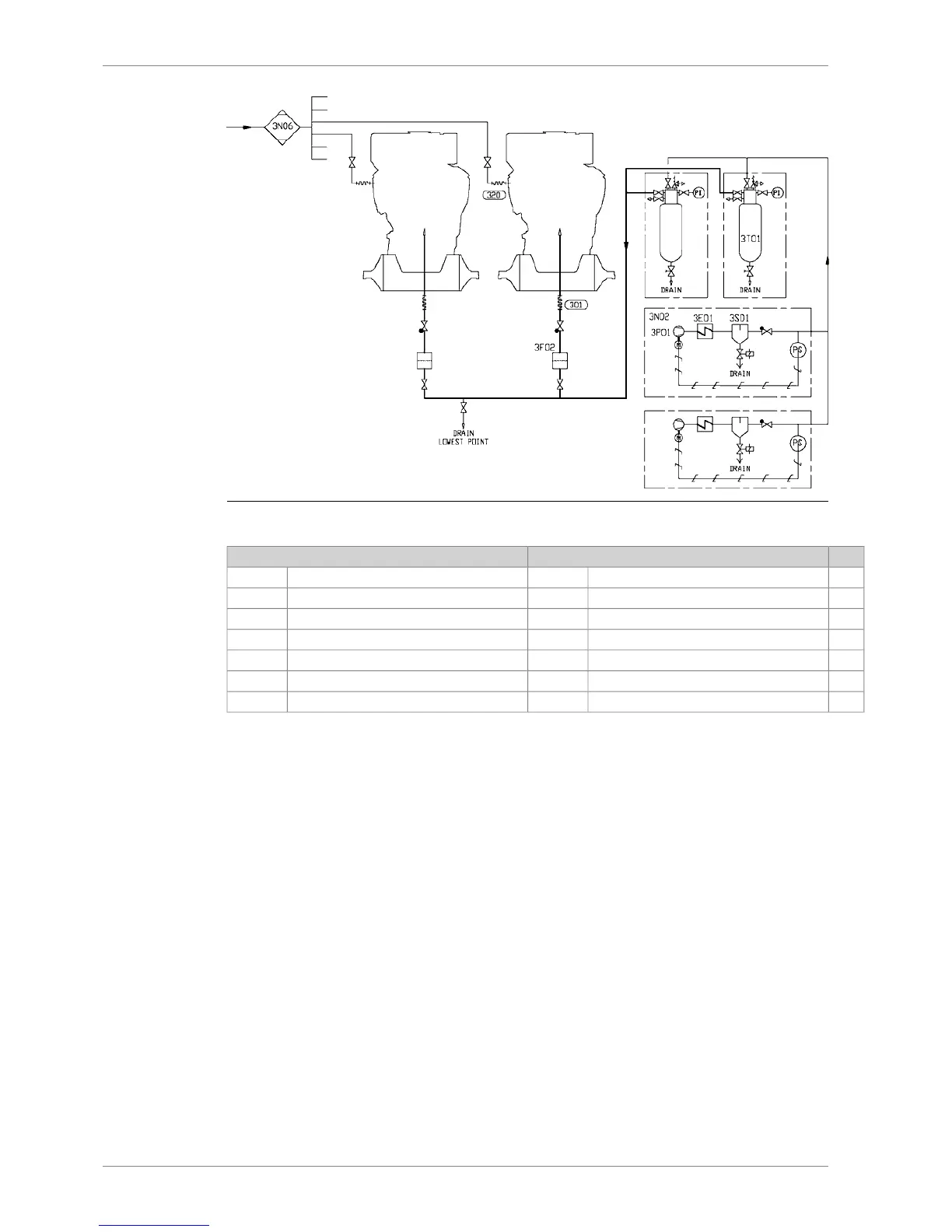

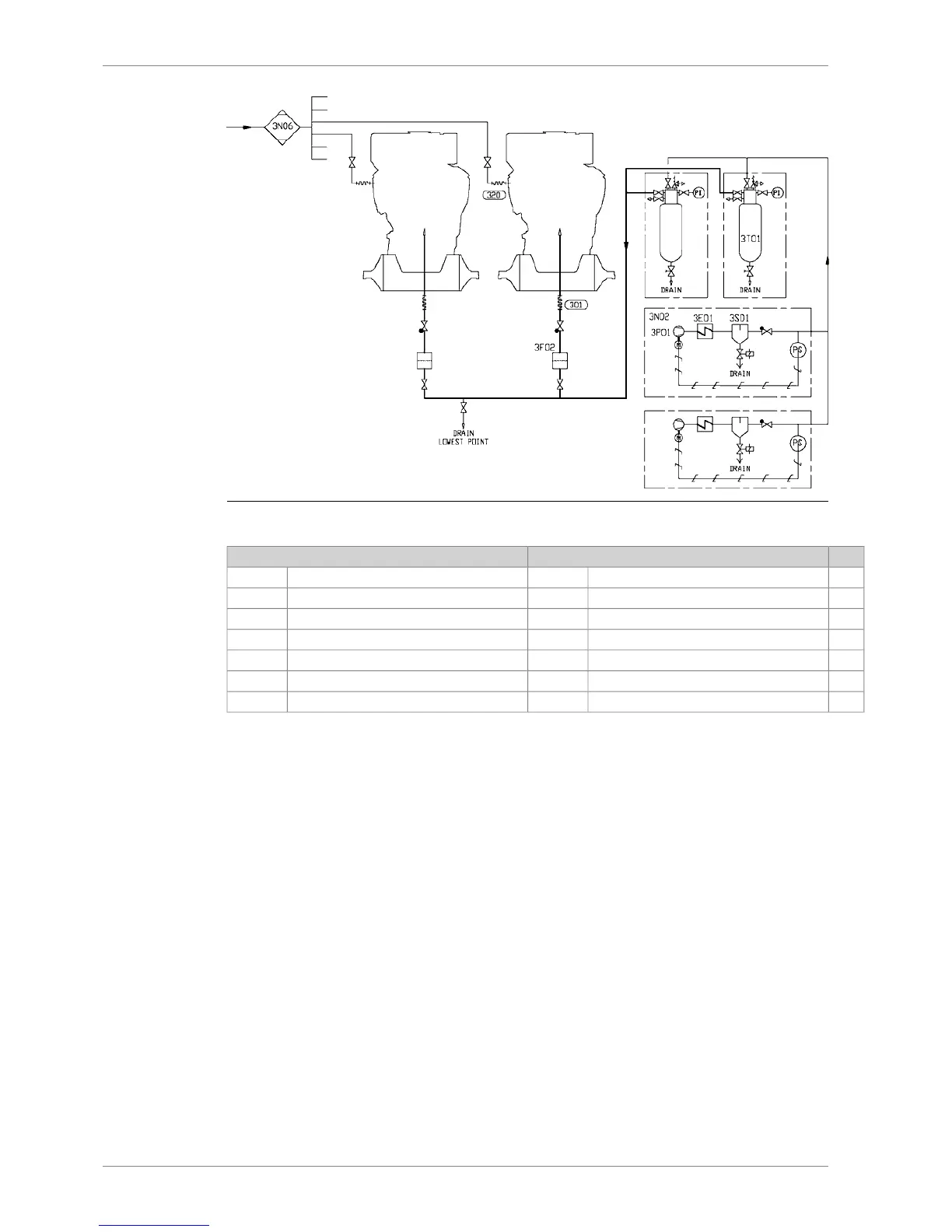

Fig 8-1 External starting air system (DAAF301502)

SizePipe connections:System components:

DN32Starting air inlet301Cooler (Starting air compressor unit)3E01

OD12Instrument air inlet320Air filter (starting air inlet)3F02

Starting air compressor unit3N02

Air dryer unit3N06

Compressor (starting air compressor unit)3P01

Separator (starting air compressor unit)3S01

Starting air vessel3T01

8.2.1 Starting air compressor unit (3N02)

At least two starting air compressors must be installed. It is recommended that the compressors

are capable of filling the starting air vessel from minimum (1.8 MPa) to maximum pressure in

15...30 minutes. For exact determination of the minimum capacity, the rules of the classification

societies must be followed.

8.2.2 Oil and water separator (3S01)

An oil and water separator should always be installed in the pipe between the compressor

and the air vessel. Depending on the operation conditions of the installation, an oil and water

separator may be needed in the pipe between the air vessel and the engine.

8.2.3 Starting air vessel (3T01)

The starting air vessels should be dimensioned for a nominal pressure of 3 MPa.

The number and the capacity of the air vessels for propulsion engines depend on the

requirements of the classification societies and the type of installation.

It is recommended to use a minimum air pressure of 1.8 MPa, when calculating the required

volume of the vessels.

8-2 DBAE248994

Wärtsilä 31DF Product Guide8. Compressed Air System

Loading...

Loading...