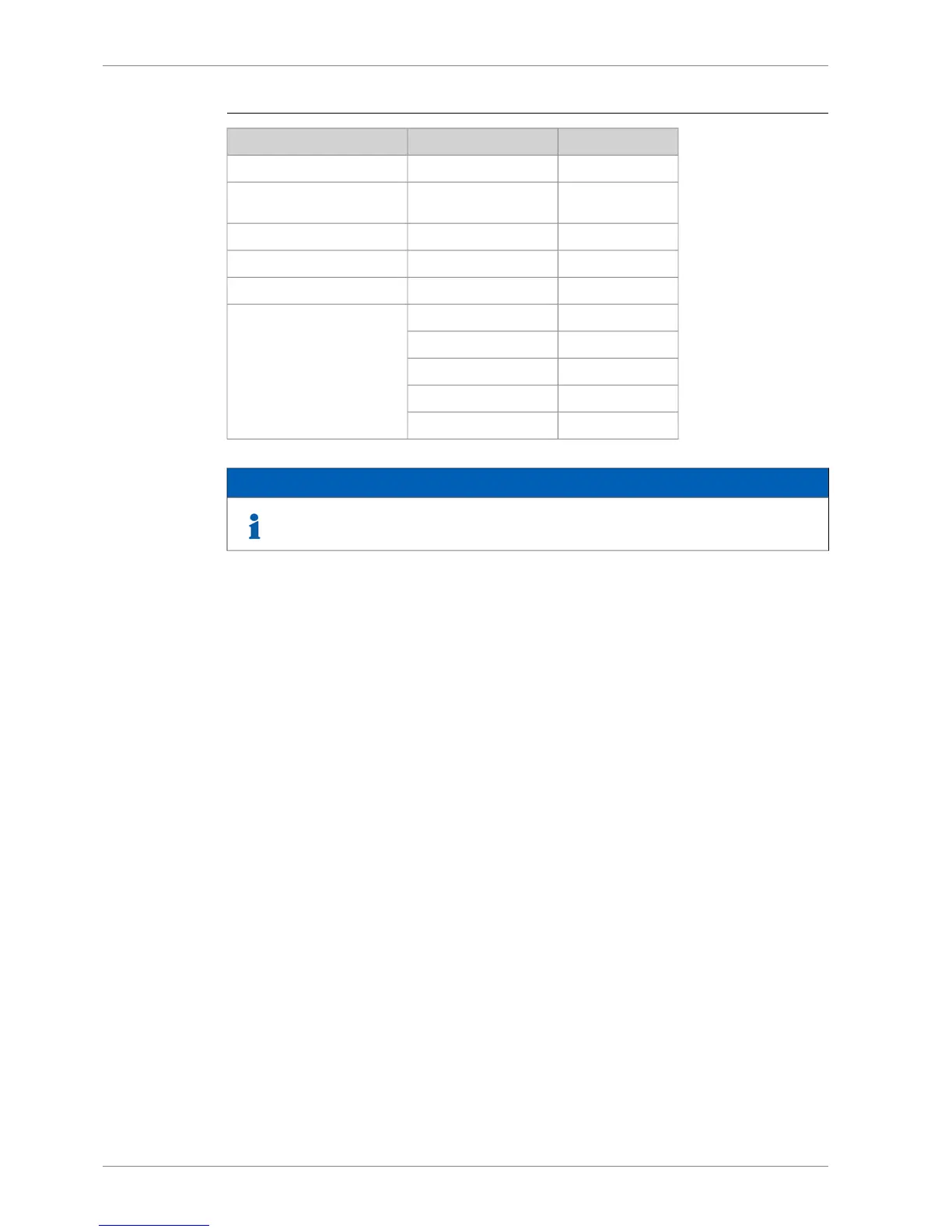

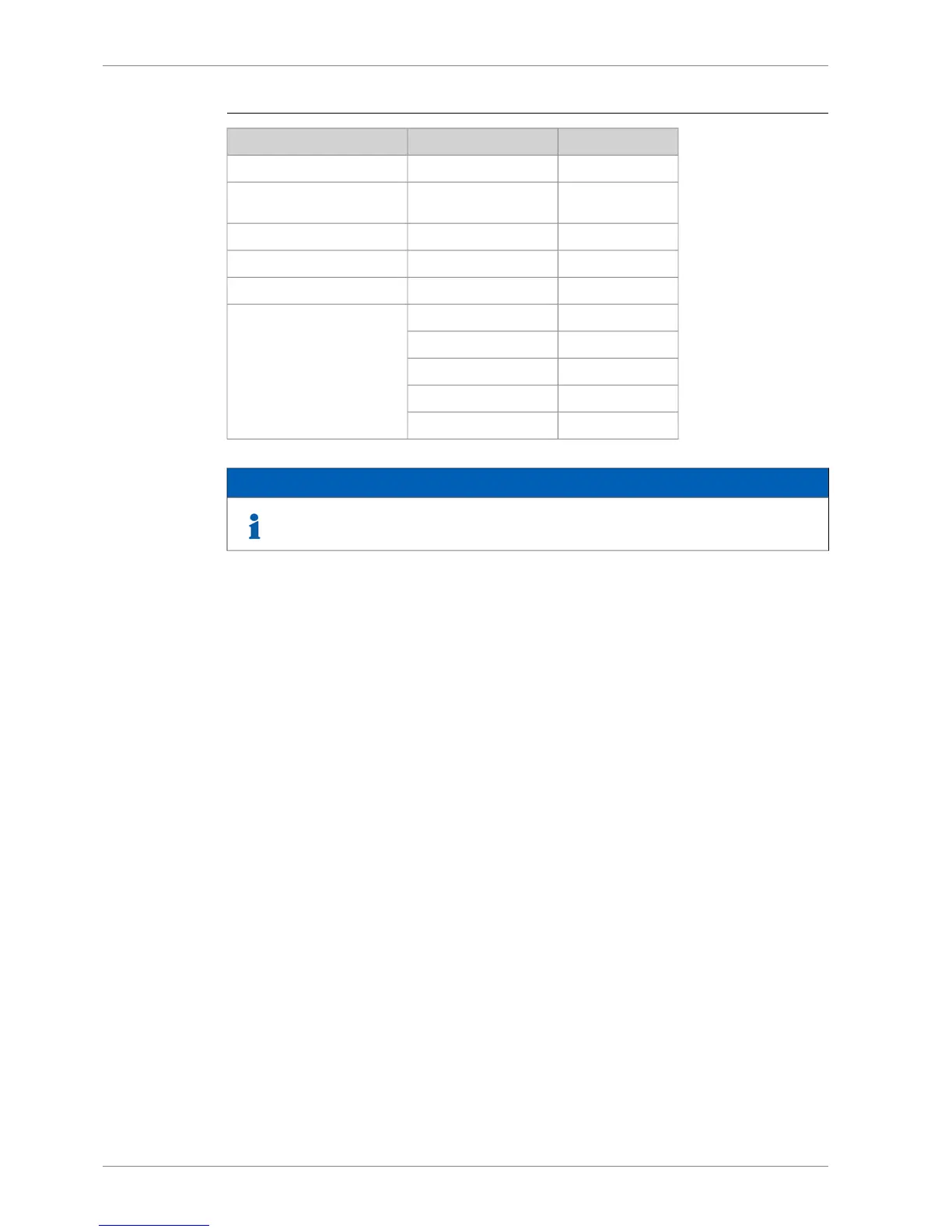

Table 5-1 Recommended maximum velocities on pump delivery side for guidance

Max velocity [m/s]Pipe materialPiping

3Stainless steelLNG piping

20Stainless steel / Carbon

steel

Fuel gas piping

1.0Black steelFuel oil piping (MDF and HFO)

1.5Black steelLubricating oil piping

2.5Black steelFresh water piping

2.5Galvanized steelSea water piping

2.5Aluminum brass

3.010/90 copper-nickel-iron

4.570/30 copper-nickel

4.5Rubber lined pipes

NOTE

The diameter of gas fuel piping depends only on the allowed pressure loss in the

piping, which has to be calculated project specifically.

Compressed air pipe sizing has to be calculated project specifically. The pipe sizes may be

chosen on the basis of air velocity or pressure drop. In each pipeline case it is advised to

check the pipe sizes using both methods, this to ensure that the alternative limits are not being

exceeded.

Pipeline sizing on air velocity: For dry air, practical experience shows that reasonable

velocities are 25...30 m/s, but these should be regarded as the maximum above which noise

and erosion will take place, particularly if air is not dry. Even these velocities can be high in

terms of their effect on pressure drop. In longer supply lines, it is often necessary to restrict

velocities to 15 m/s to limit the pressure drop.

Pipeline sizing on pressure drop: As a rule of thumb the pressure drop from the starting air

vessel to the inlet of the engine should be max. 0.1 MPa (1 bar) when the bottle pressure is 3

MPa (30 bar).

It is essential that the instrument air pressure, feeding to some critical control instrumentation,

is not allowed to fall below the nominal pressure stated in chapter "Compressed air system"

due to pressure drop in the pipeline.

5.2 Trace heating

The following pipes shall be equipped with trace heating (steam, thermal oil or electrical). It

shall be possible to shut off the trace heating.

● All heavy fuel pipes

● All leak fuel and filter flushing pipes carrying heavy fuel

5.3 Pressure class

The pressure class of the piping should be higher than or equal to the design pressure, which

should be higher than or equal to the highest operating (working) pressure. The highest

operating (working) pressure is equal to the setting of the safety valve in a system.

5-2 DBAE248994

Wärtsilä 31DF Product Guide5. Piping Design, Treatment and Installation

Loading...

Loading...