12. Turbocharger Cleaning

Regular water cleaning of the turbine and the compressor reduces the formation of deposits

and extends the time between overhauls. Fresh water is injected into the turbocharger during

operation. Additives, solvents or salt water must not be used and the cleaning instructions in

the operation manual must be carefully followed.

Regular cleaning of the turbine is not necessary when operating on gas.

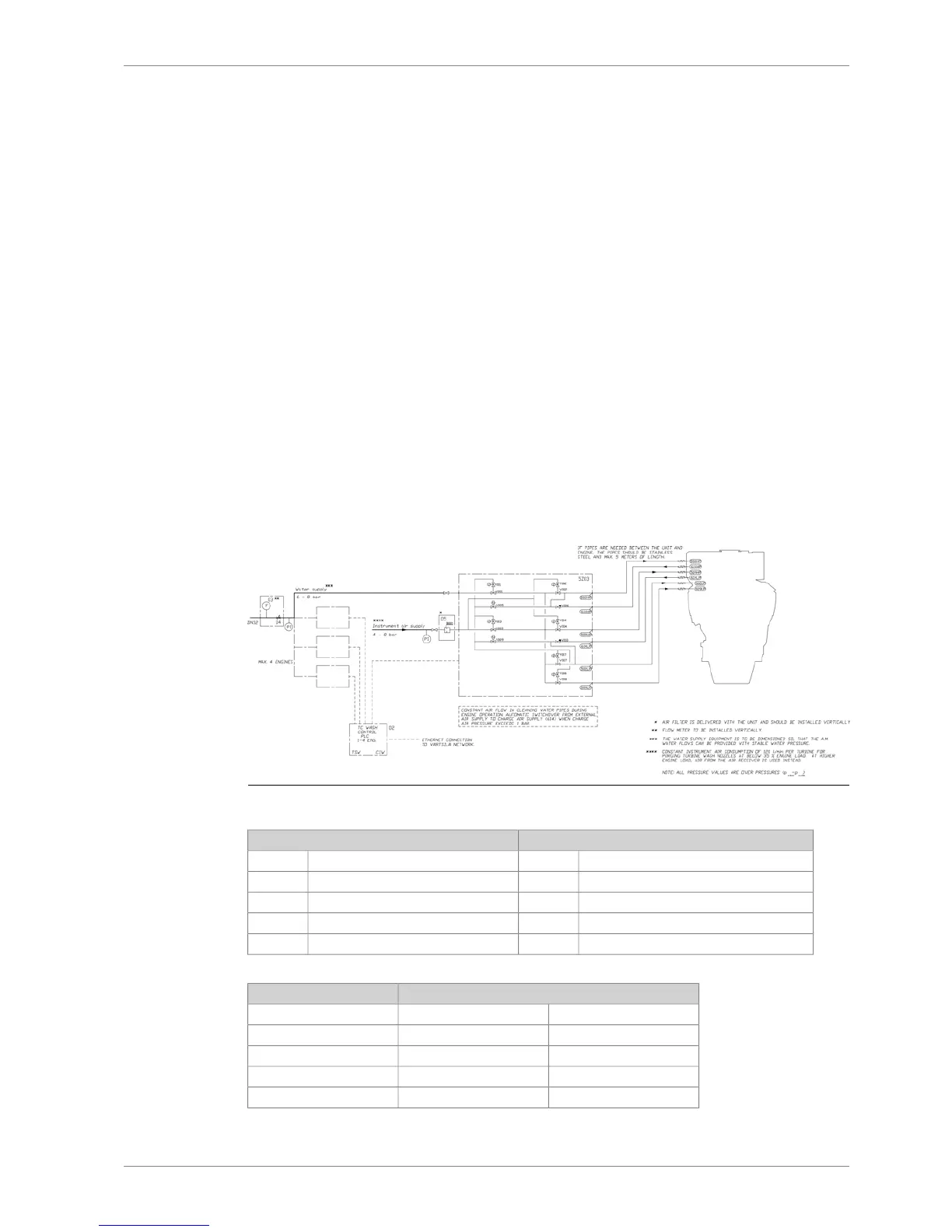

12.1 Turbine cleaning system

A dosing unit consisting of a flow meter and an adjustable throttle valve is delivered for each

installation. The dosing unit is installed in the engine room and connected to the engine with

a detachable rubber hose. The rubber hose is connected with quick couplings and the length

of the hose is normally 10 m. One dosing unit can be used for several engines.

Water supply:

Fresh water

0.3 MPa (3 bar)Min. pressure

2 MPa (20 bar)Max. pressure

80 °CMax. temperature

Fig 12-1 Turbocharger cleaning system (DAAF347567A)

Pipe connectionsSystem components

Cleaning water to turbine502##TC cleaning device5Z03

Cleaning water to compressor509##Wärtsilä control unit for 4 engines02

Scavenging air outlet to TC cleaning valve unit614##Flow meter/control (7,5 - 40 l/min)03

Flow adjustment valve, built in04

Air filter05

WaterEngine

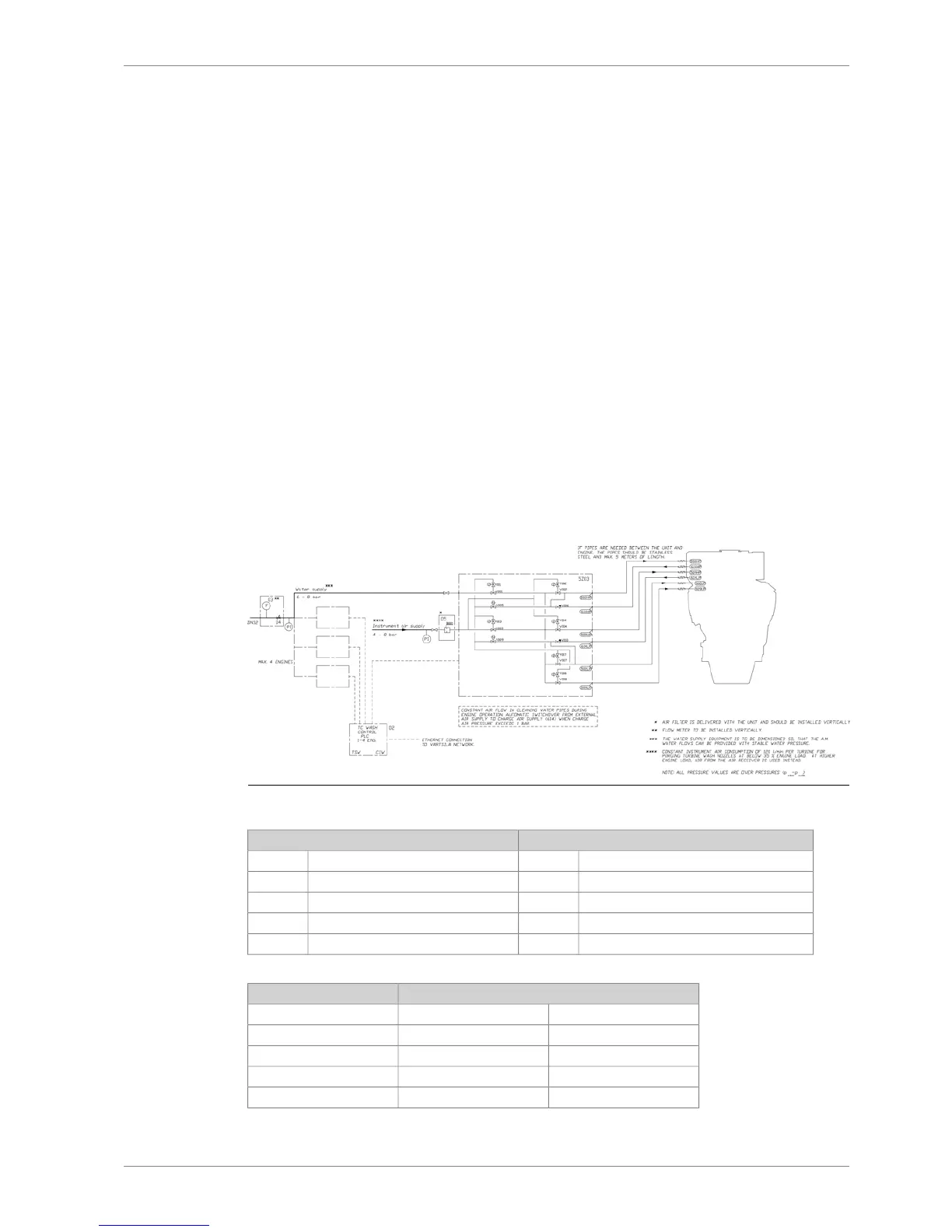

Water consumption/wash (l)Water inlet flow rate (l/min)Turbine / compressor

16.5LP-compressor

18018LP-turbine

16.5HP-compressor

22022HP-turbine

DBAE248994 12-1

12. Turbocharger CleaningWärtsilä 31DF Product Guide

Loading...

Loading...