● Ship Rules Part 6 Chapter 13, Gas Fuelled Engine Installations

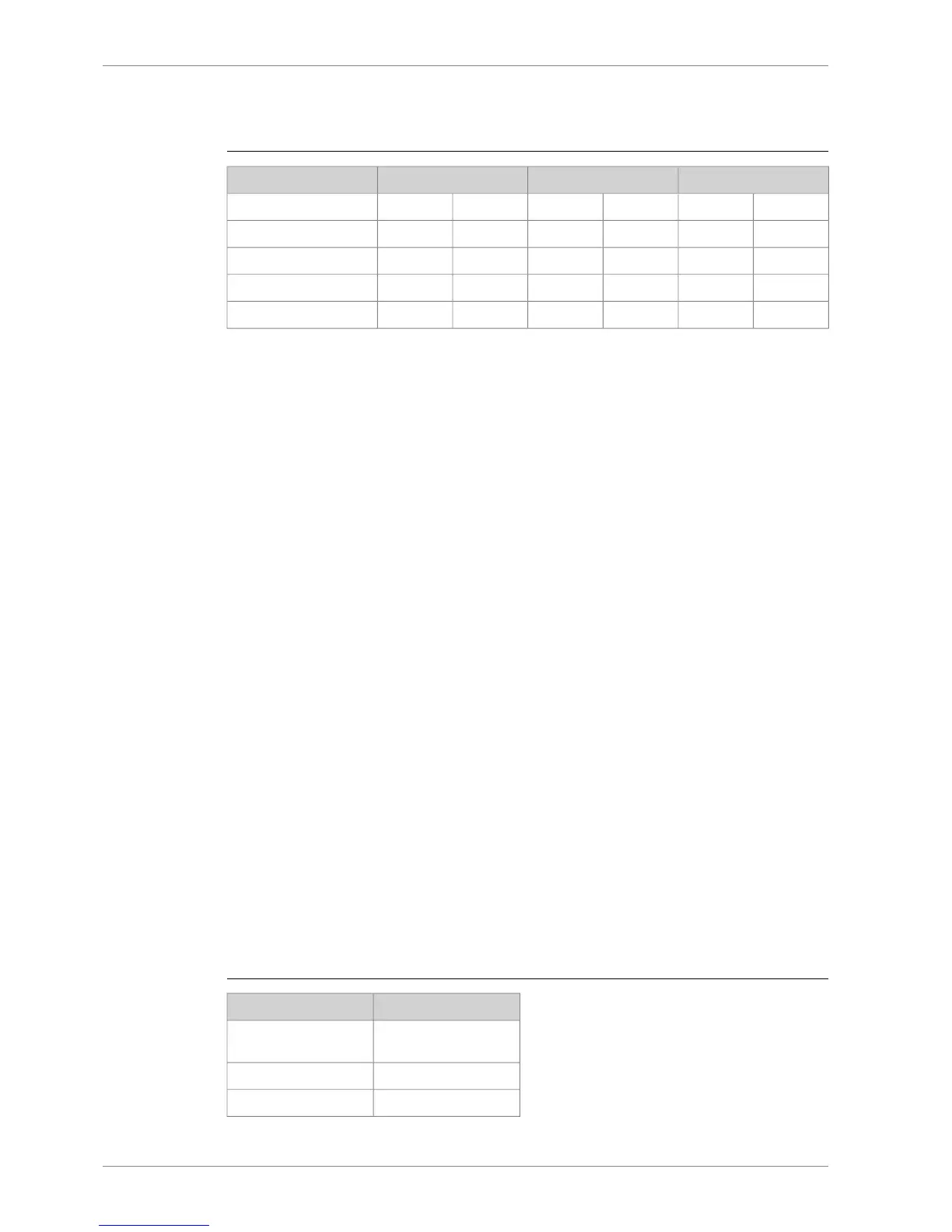

Table 5-2 Classes of piping systems as per DNV rules

Class IIIClass IIClass IMedia

°CMPa (bar)°CMPa (bar)°CMPa (bar)

and < 170< 0.7 (7)and < 300< 1.6 (16)or > 300> 1.6 (16)Steam

and < 60< 0.7 (7)and < 150< 1.6 (16)or > 150> 1.6 (16)Flammable fluid

----AllAllFuel gas

and < 200< 1.6 (16)and < 300< 4 (40)or > 300> 4 (40)Other media

5.5 Insulation

The following pipes shall be insulated:

● All trace heated pipes

● Exhaust gas pipes

● Exposed parts of pipes with temperature > 60°C

Insulation is also recommended for:

● Pipes between engine or system oil tank and lubricating oil separator

● Pipes between engine and jacket water preheater

5.6 Local gauges

Local thermometers should be installed wherever a new temperature occurs, i.e. before and

after heat exchangers, etc.

Pressure gauges should be installed on the suction and discharge side of each pump.

5.7 Cleaning procedures

Instructions shall be given at an early stage to manufacturers and fitters how different piping

systems shall be treated, cleaned and protected.

5.7.1 Cleanliness during pipe installation

All piping must be verified to be clean before lifting it onboard for installation. During the

construction time uncompleted piping systems shall be maintained clean. Open pipe ends

should be temporarily closed. Possible debris shall be removed with a suitable method. All

tanks must be inspected and found clean before filling up with fuel, oil or water.

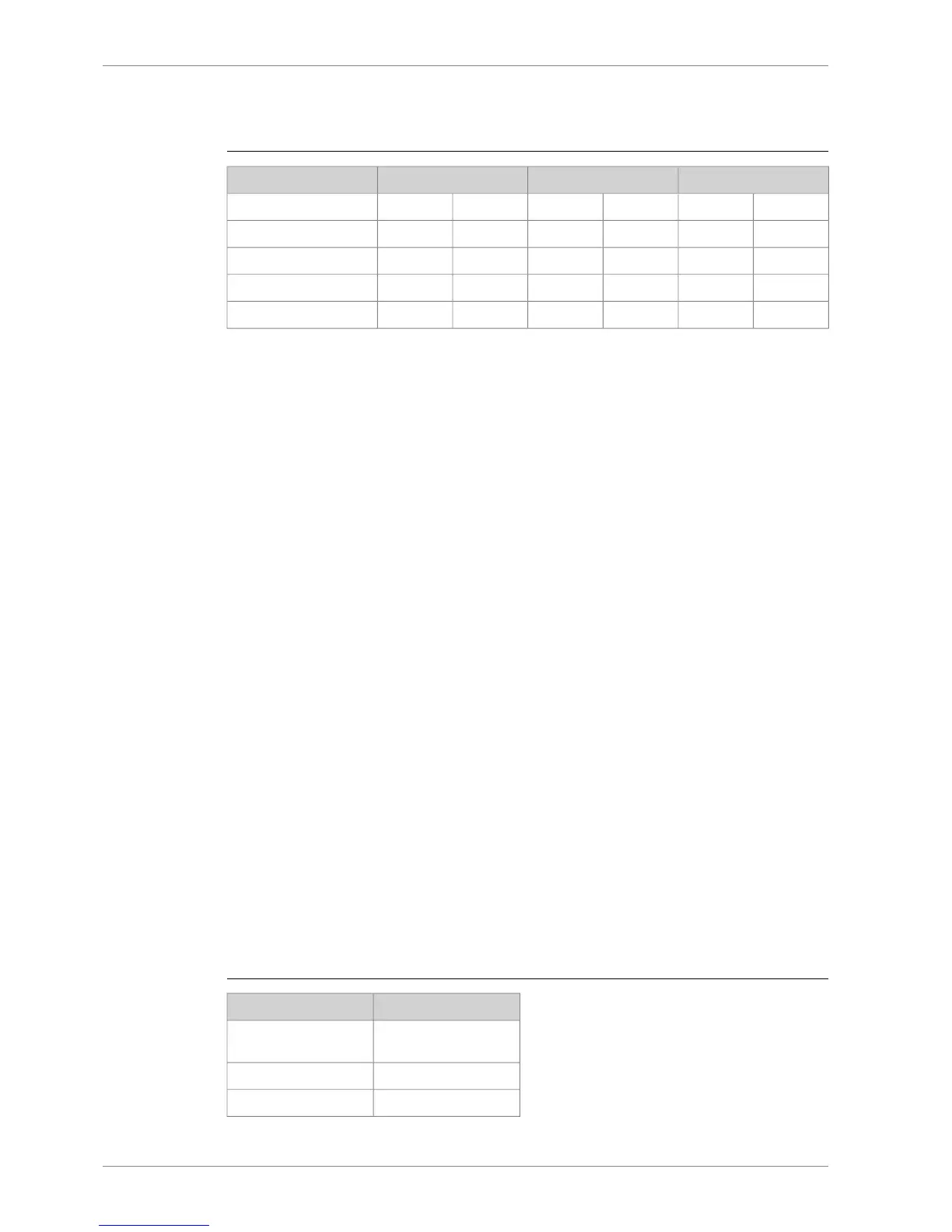

Piping cleaning methods are summarised in table below:

Table 5-3 Pipe cleaning

MethodsSystem

A,B,C

D,F

1)

Fuel gas

A,B,C,D,FFuel oil

A,B,C,D,FLubricating oil

5-4 DBAE248994

Wärtsilä 31DF Product Guide5. Piping Design, Treatment and Installation

Loading...

Loading...