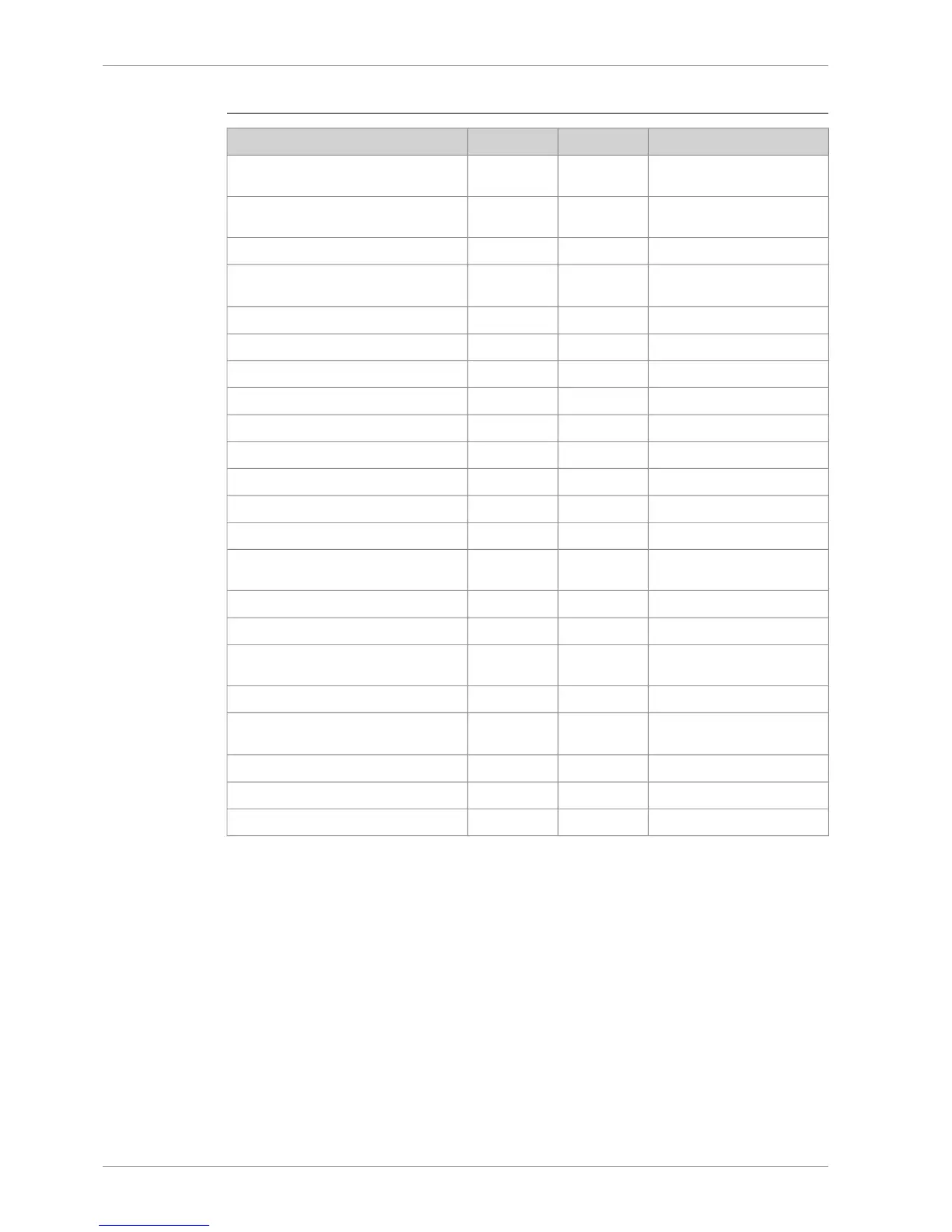

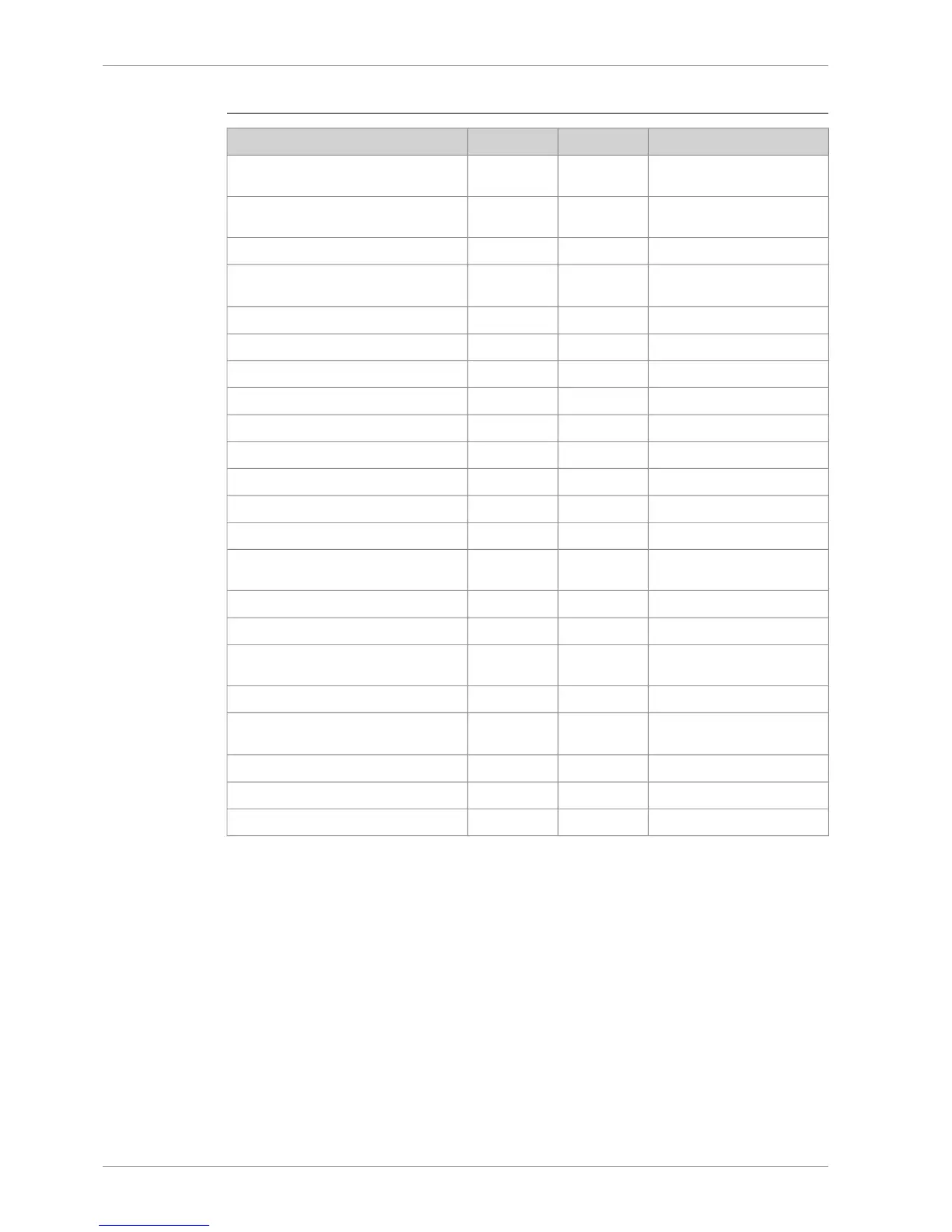

Table 6-4 Crude oils

Test method referenceLimitUnitProperty

-

2,0

e)

mm²/s

a)

Kinematic viscosity before main injection

pumps, min.

-

24

e)

mm²/s

a)

Kinematic viscosity before main injection

pumps, max.

ISO 3104700,0

mm²/s

a)

Kinematic viscosity at 50 °C, max.

ISO 3675 or ISO 12185

991,0 / 1010,0

b)

kg/m

3

Density at 15 °C, max.

ISO 8217, Annex F870-CCAI, max.

ISO 3733 or ASTM D6304-C0,30% v/vWater before engine, max.

ISO 8574 or ISO 145964,50% m/m

Sulphur, max.

c)

ISO 6245 or LP1001

f)

0,150% m/mAsh, max.

IP 501, IP 470 or ISO 14597450mg/kgVanadium, max.

IP 501 or IP 470100mg/kgSodium, max.

IP 501 or IP 47030mg/kgSodium bef. engine, max.

IP 501, IP 470 or ISO 1047830mg/kgAluminium + Silicon, max.

IP 501, IP 470 or ISO 1047815mg/kgAluminium + Silicon bef. engine, max.

IP 501 or 500 for Ca and ISO

10478 for K and Mg

50mg/kg

Calcium + Potassium + Magnesium bef.

engine, max.

ISO 1037020,00% m/mCarbon residue, micro method, max.

ASTM D327914,0% m/mAsphaltenes, max.

ASTM D32365kPa

Reid vapour pressure, max. at 37.8°C,

max.

ISO 301630°CPour point (upper), max.

ISO 3015

IP 309

60

d)

°CCloud point, max. or

Cold filter plugging point, max.

ISO 10307-20,10% m/mTotal sediment aged, max.

IP 399 or IP 5705,00mg/kgHydrogen sulfide, max.

ASTM D6643,0mg KOH/gAcid number, max.

6-8 DBAE248994

Wärtsilä 31DF Product Guide6. Fuel Oil System

Loading...

Loading...