Flameproof motors | 19

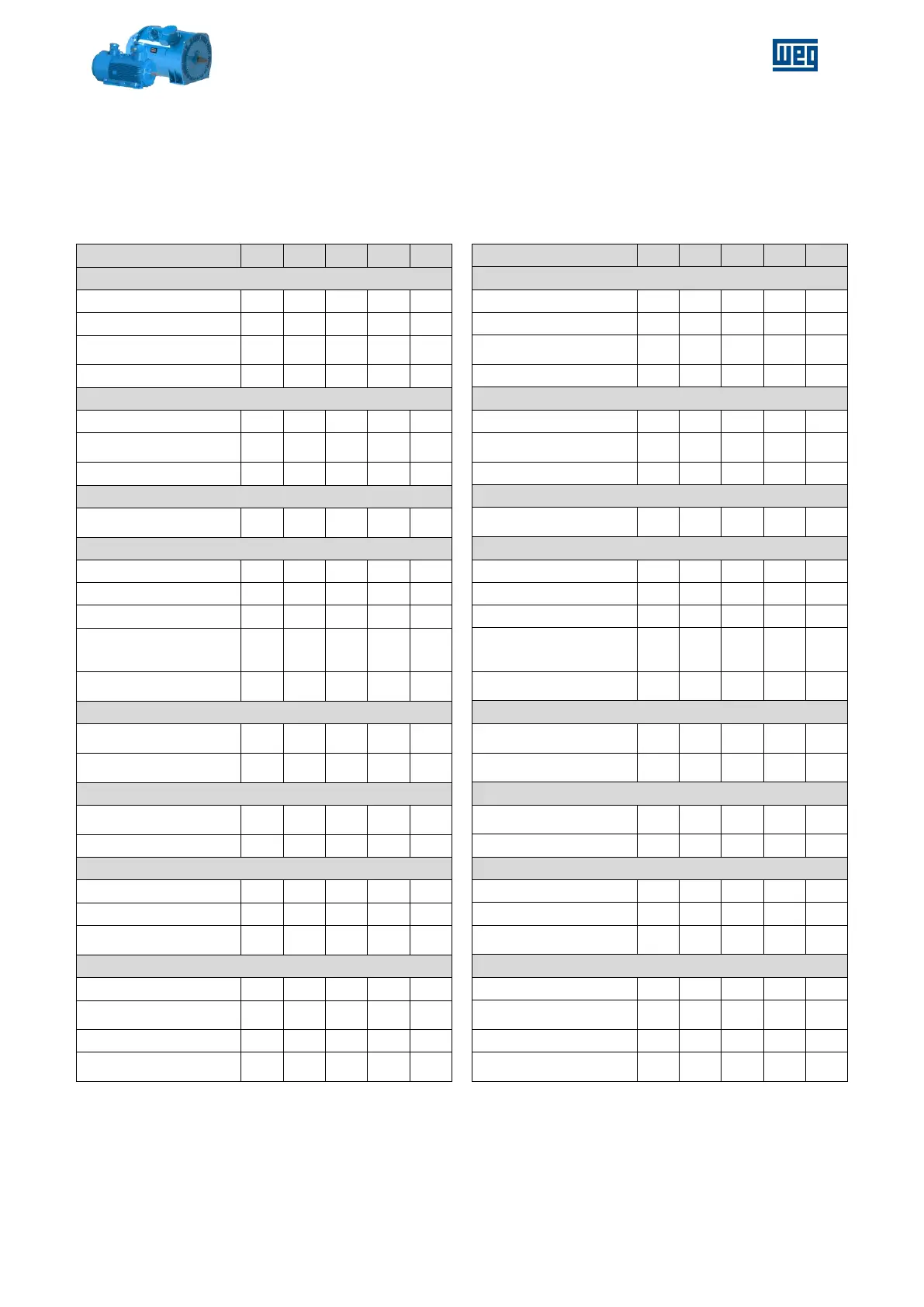

3.7.13. MAINTENANCE PLAN FOR STORAGE

During the storage period, the motor maintenance

must be executed and registered according to the

plan described in the table below:

Table 3-4 - Maintenance plan for indoor storage

Check for signs of insect

infestation

Relative Humidity inside

Motor

Check operation

conditions

Perform External Cleaning

Check Painting Conditions

Check Oxidation Inhibitor

on Exposed Machined

Parts

Replace the Oxidation

Inhibitor

Measure Insulation

Resistance

Measure Polarization

Index

Terminal Box and Grounding Terminals

Clean the boxes inner

parts

Inspect Seals and Sealing

Disassemble / Clean

Bearings

Apply Anticorrosive and

Dehumidifier

Clean / Lubricate Bearings

Disassemble / Store

Bearing Parts

1)

After rotate, positioning the shaft at 45º from the original

position.

1M All inspections that must be performed and recorded on

a monthly basis;

2M All inspections that must be performed and recorded

every two months;

6M All inspections that must be performed and recorded

every six months;

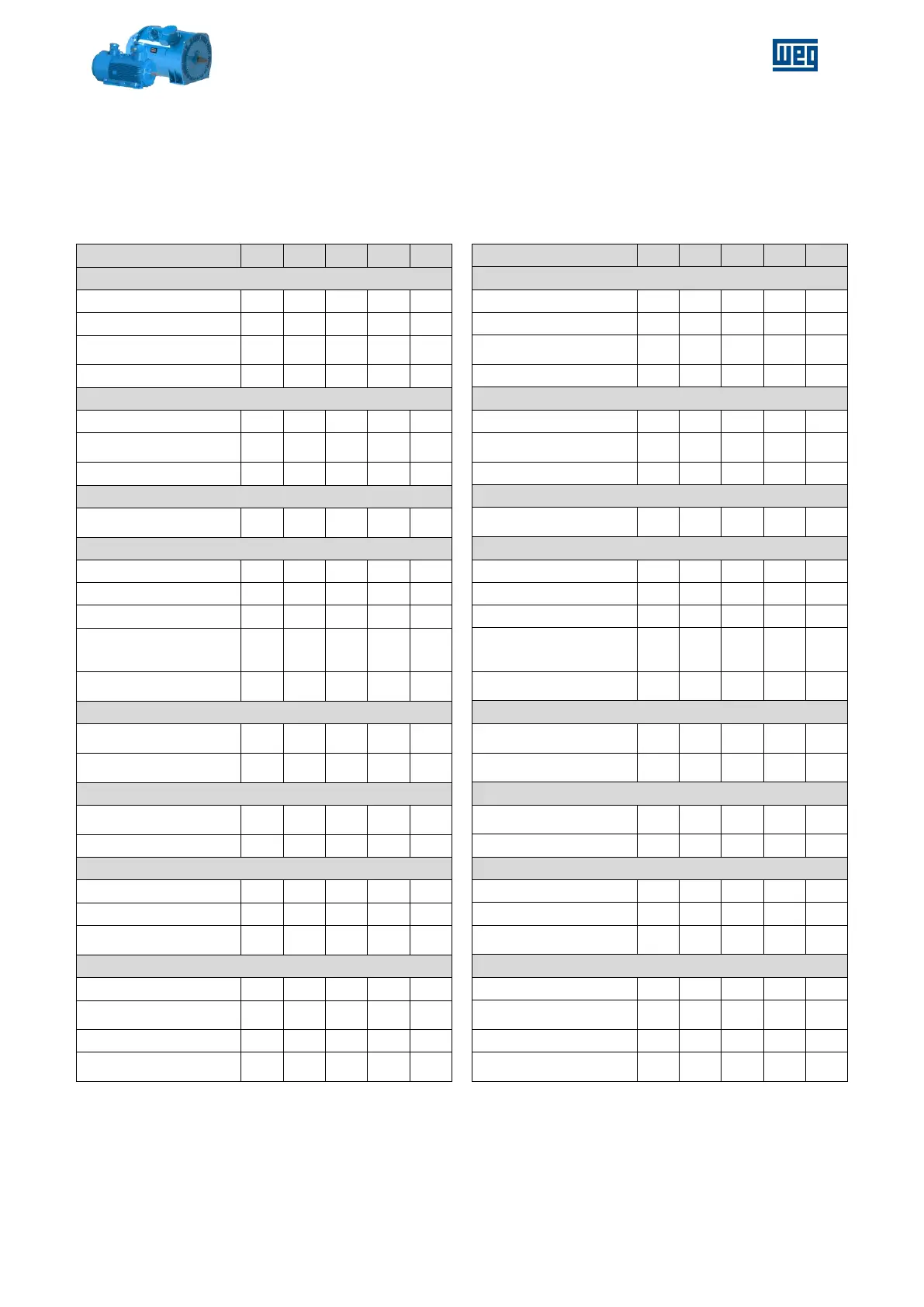

Table 3-5 - Maintenance plan for outdoor storage

Check for signs of insect

infestation

Relative Humidity inside

Motor

Check operation

conditions

Perform External Cleaning

Check Painting Conditions

Check Oxidation Inhibitor

on Exposed Machined

Parts

Replace the Oxidation

Inhibitor

Measure Insulation

Resistance

Measure Polarization

Index

Terminal Box and Grounding Terminals

Clean the boxes inner

parts

Inspect Seals and Sealing

Disassemble / Clean

Bearings

Apply Anticorrosive and

Dehumidifier

Clean / Lubricate Bearings

Disassemble / Store

Bearing Parts

1)

After rotate, positioning the shaft at 45º from the original

position..

2Y All inspections that must be performed and recorded

after 2 years;

BS All inspections that must be performed and recorded

before Start-up;

Loading...

Loading...