32 | Flameproof motors

The alarm and tripping values of the Table 5-5

represent values of permissible shaft vibration for

coupled electric machines. These values are below

ISO 7919-3 Standard.

They are generic values and serve as a guideline,

where specific application conditions must be taken

into consideration, mainly diametric clearance

between shaft and bearing.

Table 5-5 - WEG limits for shaft vibration

Shaft vibration (μm peak to peak)

Operate the motor with shaft

vibration values close to alarm and

tripping values can damage bearing

liners.

The main reasons to cause increase of vibration

are:

- Unbalance coupling problems and others that

can affect the machine;

- Shaft manufacturing problems, which are

minimized during the manufacturing;

- Residual voltage or magnetism on the shaft

surface where measurement is made;

- Scratches, knocks or vibrations when finishing

the shaft where measurement is made.

5.1.9. AUTOMATIC LUBRICATORS

If motor is supplied with motor lubrication it is

mandatory to activate them at start-up.

For details regarding activation of automatic

lubricators refer to sub-section 8.2.9.

ELECTRICAL ASPECTS

5.2.1. POWER SUPPLY

Make sure the motor is connected to the correct

power supply.

Proper electric power supply is very important. All

the wires and protection system must ensure an

excellent quality of electric power supply on the

motor terminals.

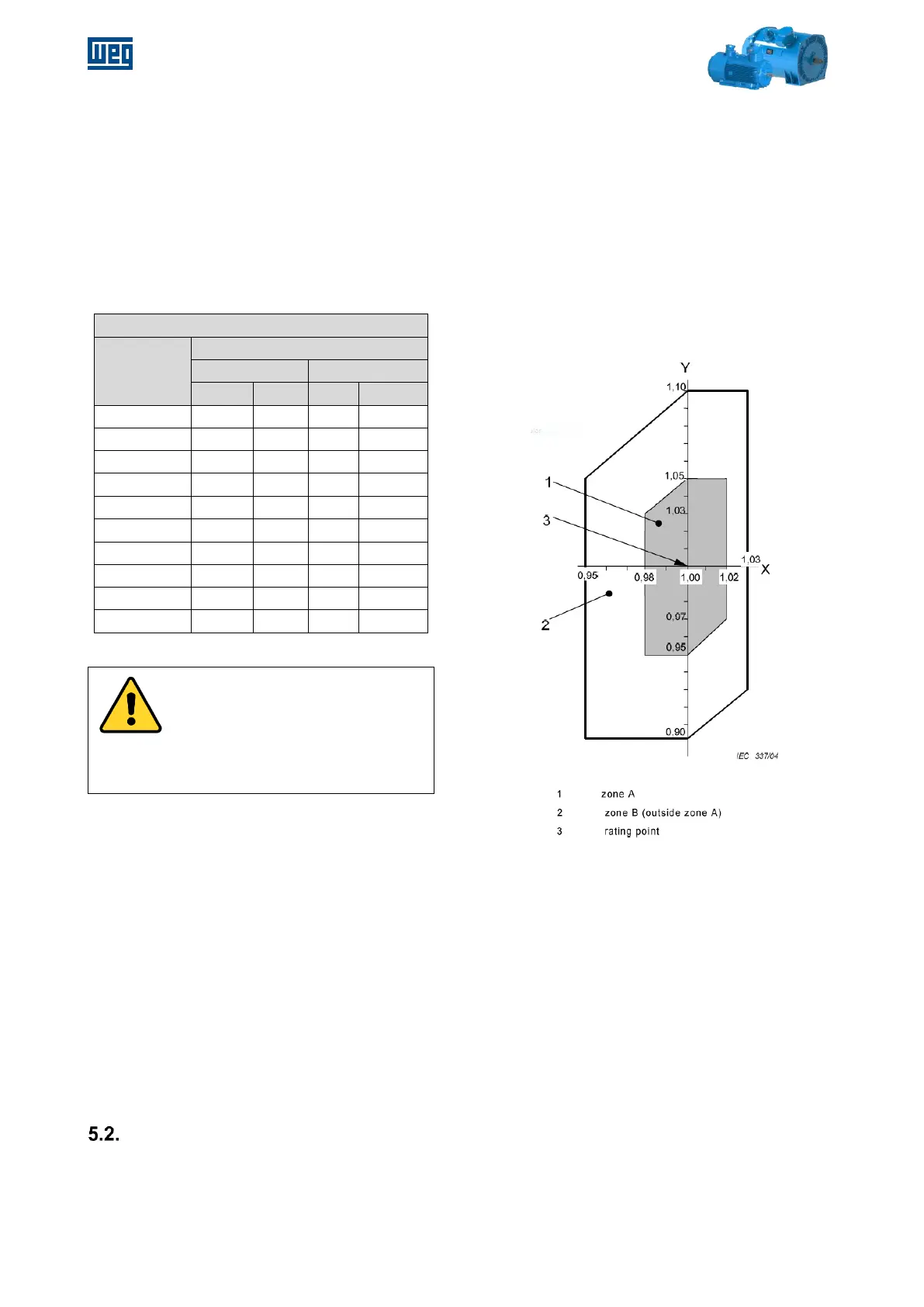

The WEG motors are constructed in accordance

with IEC 60034-1 and, unless otherwise stated on

motor data-sheet, they are designed for a rated

voltage of more or less than 10% in relation to rated

value (zone “B” in Figure 5-18).

For rated frequency, a variation of 95% to 103%

(zone “B”) is allowed.

Figure 5-18 - Voltage and frequency variation limits

(IEC 60034-1)

The motor must be able to perfom its main function

(supply torque) continuously at Zone A, but it does

not have to fully meet its performance

characteristics at rated voltage and frequency

(refer to the point with rated characteristics in

Figure 5-18), and it may present some deviations.

The temperature rises values when the motor is

working in the Zone A may be higher than those

obtained at rated voltage and frequency.

The motor must also be able to perform its main

function in Zone B, but it may present greater

deviations of its performance at rated voltage and

frequency than in Zone A. The temperature rises

may be higher than those observed at rated voltage

and frequency and, most likely, will be higher than

those in Zone A.

Prolonged operation in the periphery of Zone B is

not recommended.

Loading...

Loading...