20 | Flameproof motors

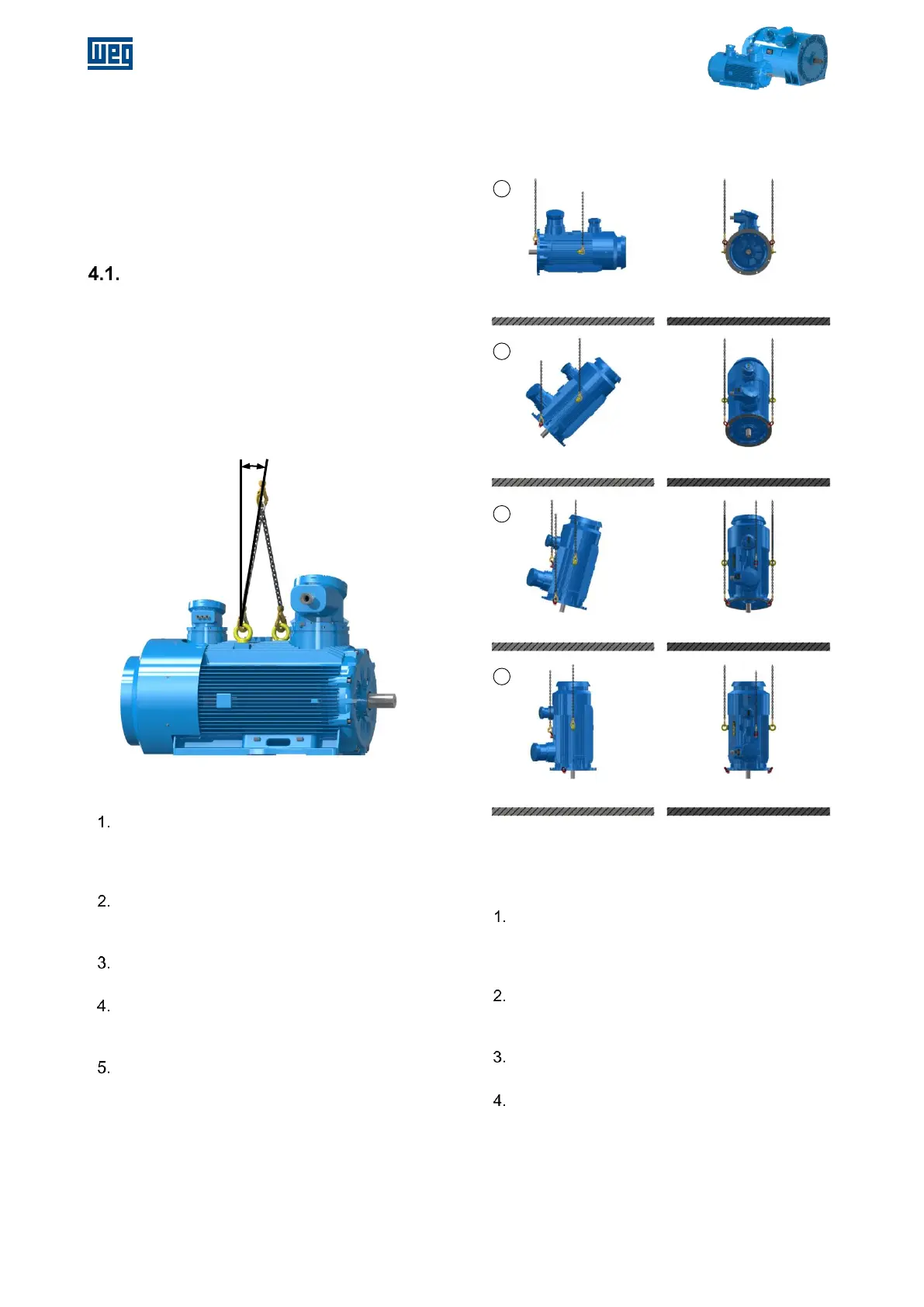

4. HANDLING

Use only the existing eyebolts to lift the motor.

Never lift the motor by the shaft. Check the motor

weight. Lifting and lowering must be done gently in

order to avoid damage to the bearings.

HANDLING RIBBED COOLED

MOTORS

4.1.1. HORIZONTAL MOTORS

The eyebolts attached to endshields, fan cover, etc,

should be used to handle these specific

components only. The complete motor should be

lifted only by the eyebolts in the frame.

Figure 4-1 - W22Xd LINE – horizontal ribbed cooled

motors

Lifting lugs on the frame are designed for

lifting machine only. Do not use for lifting

coupled equipment such as pumps,

compressors, gears or other equipment;

The chains or handles of hoisting must have

on maximum angle of 30º with regard to

vertical line:

Use all of eyebolts fixed in the frame, supplied

together with the motor;

Failure to observe these precautions may

result in damage to the equipment, injury to

personnel or both.

When the risk of motor damage exists by the

lifting chains, special tools must be predicted

by the customer.

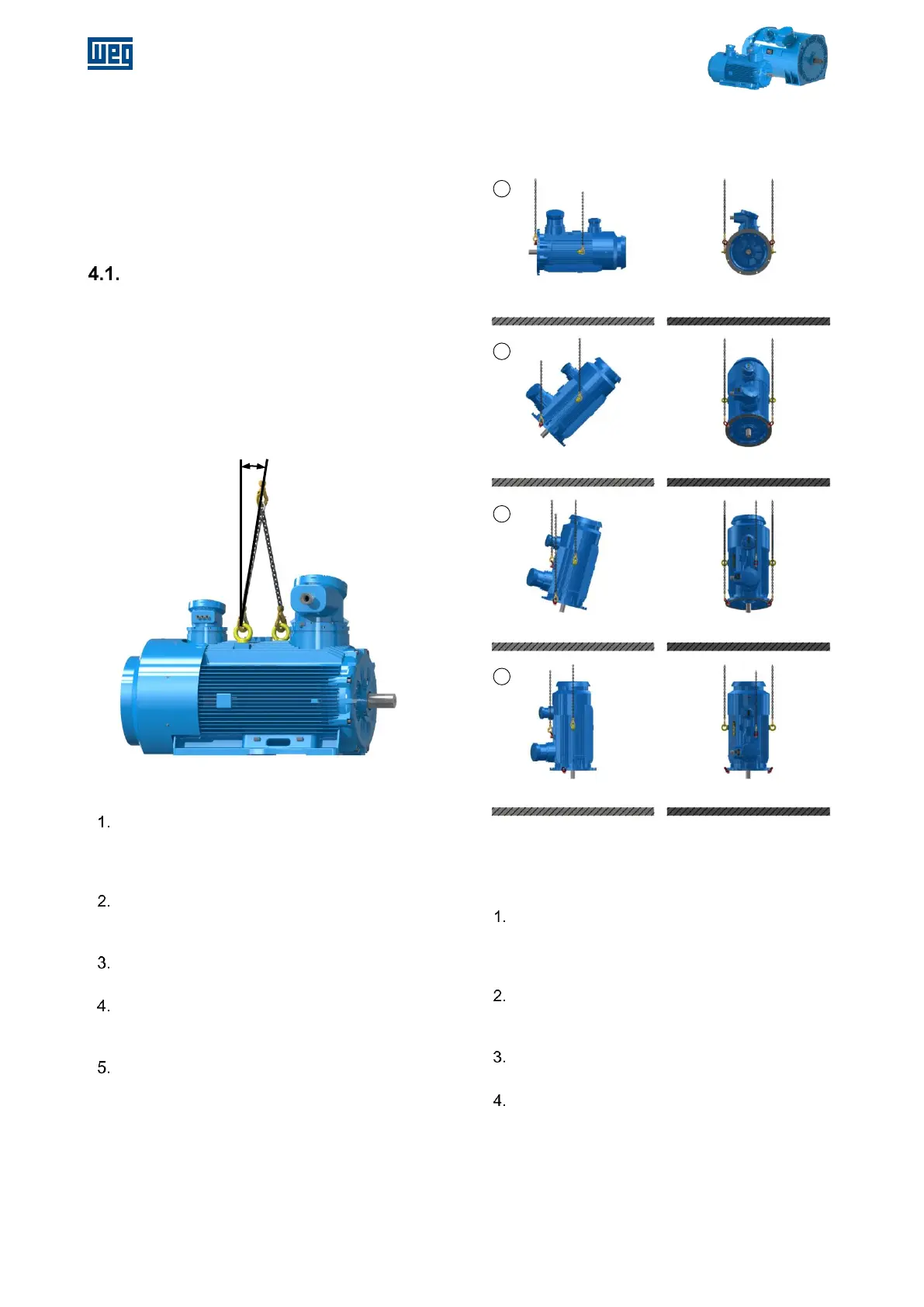

4.1.2. VERTICAL MOTORS

Figure 4-2 - W22Xd LINE – vertical ribbed cooled motors

The handling of the vertical ribbed cooled motors

must be done as showed in the Figure 4-2.

Lift the motor using 2 cranes and 4 eyebolts:

2 chains or cables in motor eyebolts (b) and

2 chains or cables in flange eyebolts (a); (see

detail in Figure 4-3)

Lower the crane that is holding the flange

eyebolts (a) and simultaneously lift the crane

holding motor eyebolts (b);

Attach a third chain or cable (c) to the crane

holding motor eyebolts (b);

Continue to lower the crane attached to

flange eyebolts until motor is in vertical

position and remove flange chains and

eyebolts (a).

1

2

3

4

a)

b)

a)

b)

a)

b)

c)

c)

b)

c)

b)b)

a) a)

b)

a)

b)

a)

b)

a)

b)

a)

b)b) c)

Loading...

Loading...